1 / 5

High Output Wood Pellet mill

| Model No. : | SZLH660 |

|---|---|

| Brand Name : | Kingoro |

| Voltage : | 380V |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Video

Product description

High output Wood Pellet Machine:

High Output Wood Pellet mill is applied to the materials with low adhensiveness and low shaping rate such as rice husk, suflower seeds husk, peanut shell husk, and other nut shell and fruit shells, this pellet mill is widely used in the biomass-energy fules plant, power plant, wood processing plant, it is the ideal pressing shaping machine with low investments and high profit.

Biomass Vertical Ring Die Wood Pellet Making Machine is applied to the materials with low adhesiveness and low shaping rate such as the rice husk,sunflower seed husk,peanut shell and other fruit shell;branch,trunk,bark and other wood waste;a variety of corp straws,rubber,cement,ash and other chemical materials.This type of pellet mill is widely used in the biomass-energy fuels plant,wood processing plant,fertilizer plant,chemical plant etc,It is ideal pressing shaping equipment with low investment and high profit.

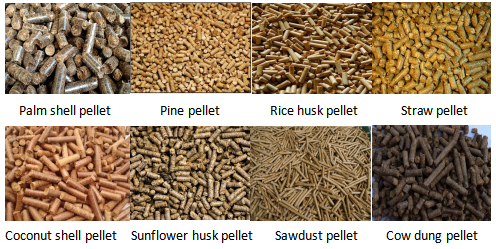

Vertical Ring Die Wood Pellet Machine Applicable Material:

Pellets are a solid biomass fuel, mainly produced from wood residues but also from agricultural by-products such as straw. They have a cylindrical form with a diameter of 6 – 12 mm. Applicable for:residential heating, power generation, and for heat generation in the manufacturing and energy sectors.

Wood pellets making process:

Features:

1.Mold static vertical installation,easy fixed,stable performance

2.Stand Mold,vertical feed, No arch camber,good heat radiation

3.Roller rotation,make the material produce centrifugal force,well-distributed

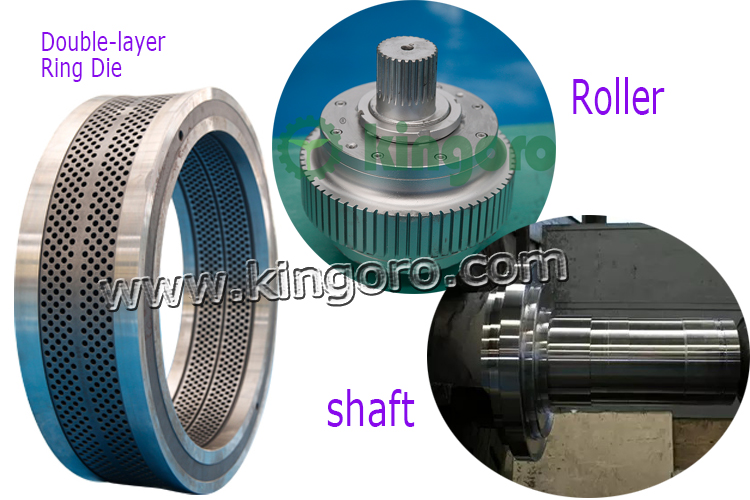

4.double layer mold,Up and Down dual-use,decreasing cost and increasing benefit

5.With high precision cylindrical in volute helical gear drive directly, transmission efficiency

Machine advantages:

1.Feeding vertically and direct in place, with stationary die and rotary pinch roller, the material is centrifugal and equispaced around the die

2.Double-ring die, can use for substitute

Die is the core part of the wood pellet machine, customer can adjust the pellet machine with different thickness and compression ratio to adapt to different materials and realize best pelletizing result.

3.Vertical hopper: this design can avoid the raw material be stuck in granulating room

4.Unique automatic lubricating system: lubricate the bearing, dies and rollers, increase the produce efficiency and reduce energy consumption. It can work continuous 20 hours.

Vertical Ring Die Wood Pellet Machine Specification:

Model

SZLH470L

SZLH560

SZLH560G

SZLH580

SZLH600

SZLH660

SZLH760

SZLH850

Power (kw)

Capacity (t/h)

Weight (T)

55

0.7-1

2.6

90

1.2-1.5

5.6

132

1.8-2

6.5

90

1-1.5

5.5

110

1.3-1.8

8.6

132

1.5-2

8.8

160

1.5-2.5

9.6

220

2.5-3.5

13

Details of Wood Pellet Maker:

Spare parts:

Certificate:

Our customers:

our product has been sold to different countries including UK, Serbia, Indonesia, Malaysia, Vietnam, Bangladesh ,Ghana, Suriname etc.

After service:

24 Hours Online Service.

Free training for operation, debugging and daily maintenance.

We can provide professional guide installation.

One year warranty and all-round after-sales service.

1.We need to know the following information to give a quote and solution

1)What is your raw materials? (to confirm mould pressure ratio of machines )

2) What is the moisture content of your raw material?

3)How many output capacity do you want per hour / month/ year?

Note: If the moisture is high, you need a dryer, because the suitable moisture content to enter pellet machine is 10-15%.

And please provide us above detailed information, then we would design the most suitable production line with reasonble offers.

2. Q: How long is your guarantee?

A: 12 months warranty but except quick wearing parts.

3. Q: Voltage requirement ?

A: Our machines can use 380V, 220V, 240V, 415V, 480V, and 50Hz, 60Hz.

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Video

Send your inquiry to this supplier