1 / 5

high frequency welded pipe making machine

| Model No. : | ZT-008 |

|---|---|

| Brand Name : | ZHONGTUO |

| Application : | Decoration |

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

Metal steel high frequency welded pipe making machine

High technology apply to the pipe making, PLC contorl system, work statble and easy operate and maintain. On he construction and precision to ahieve the advance level in this field. From the feeding to cut to product, machine work speed can be adjusted with the pipe sizes change.

One machine can make the round pipe, square pipe and the rectangular pipe, we will match the right machine type according to the pipe size and material thickness.

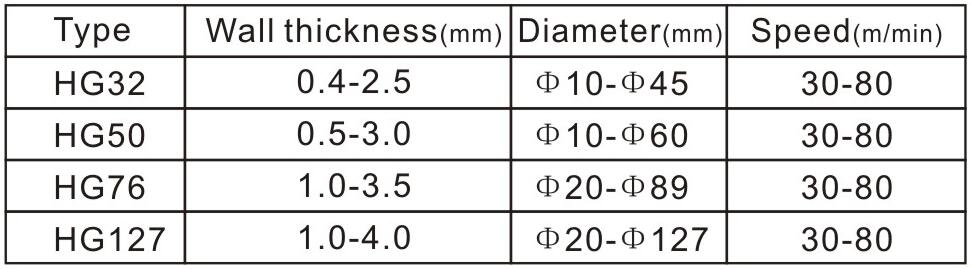

Here is the main types for the pipe making machine:

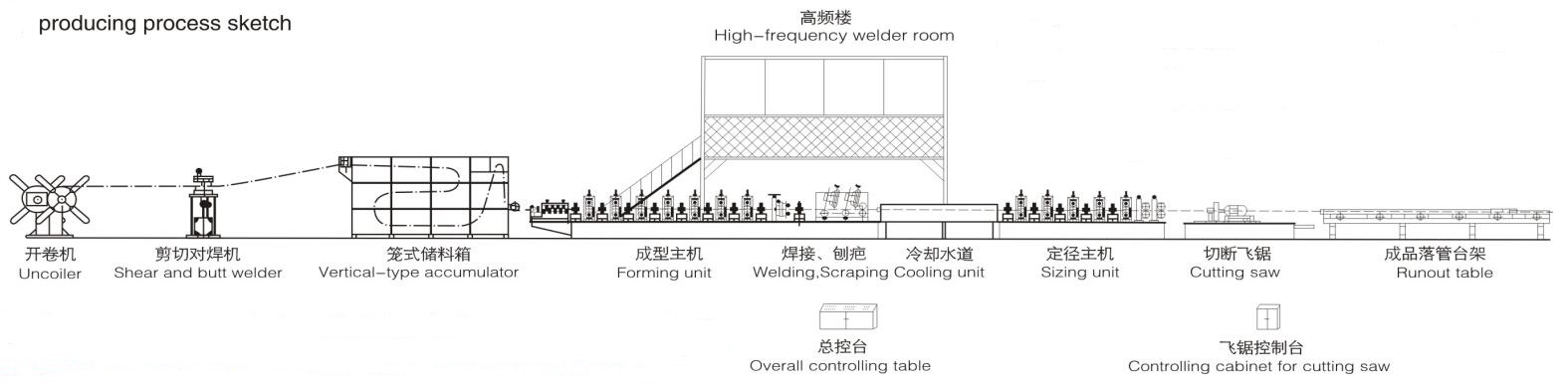

The whole production line include the uncoiler, shear and butt welder, vertical type accumulator, forming unit, high frequency welded system, sizing unit, the cutting system and powerful product table.

The product flow photo can help you to know how the machine working:

We will provide the double head uncoiler with the pipe making machine, the double head uncoil can change the coil very fast, so that it can match the high working speed. Each head can load the coil of 1.5-2 tons. Here is the uncoil photo please check:

For the material storage we have two types machine for choice:

The first one is vertical type accumulator, the function is to in store enough material keep the machine working when material cutting and welding.

1. construction: steel plate welded, with auto-feeder and pull material unit

2. adjust way: by hand

3. storage capacity: 150-300m,

4. length: 5.5*2.8m

The second type is the horizontal accumulation, the main function is to store a certain amount of steel strip for supplying main machine before it doing head and end welding to make sure main machine's continuous production without stopping.

1. accumulation diameter: 5m

2. coil width: 240*530mm(accoding to the pipe size)

3. coil thickness: 1.5-4mm (accoding to the pipe size)

4. feeding speed: 120-200m

Structural form: reversing stand, pinch feeding structure (22kw AC speed-adjusting motor), main body of accumulator (30kw AC speed-adjusting motor)

The two types units function is same, according to the machine productivity the customer can choose the one he wants. The first one can save much cost compared the second type, but the material store length is less than the second one. The second type can work more steady and protect the material surface without damage and more length instore.

The shaft material is 40Cr, and Roller material is Cr12 for both the forming unit and sizing unit. The shaft numbers depend on the pipe size or machine type.

As we know, no matter what pipe shape we make, the first step is to make it round, that's what the forming unit do.

The sizing machine with mold will make the shape for what we need, like the round shape, square pipe and the rectangular pipe. Both the forming unit and sizing unit will include the Turkey head, it can guide and straightening the pipe more better to the next unit.

Between the forming unit and sizing unit, we will put the high frequency welded system. It's made in Baoding city,

solid statehigh frequency welder, Rectifier cabinet, Inverter cabinet, transformer, worktop, wind and water cooling system.

For the transmission system, the unit adopt the forming machine and sizing machine drive system, the main motor through reducer, gear box, universal drive shaft drag the horizontal roller, vertical roll for non powered roller.

The cutting system is the computer controled flying saw cutting, it can match the machine producing speed. The tracking cutting make it more safe.

We provide the 9 meter's long powerful table to collect the product.

Cangzhou, Hebei, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier