1 / 4

High fracture zirconia ceramic shaft sleeves for micropump

Get Latest Price

Send Inquiry

| Model No. : | SMK010602 |

|---|---|

| Brand Name : | Seamark |

Suzhou Seamark Fine Ceramics Co., Ltd.

You might also like

Product description

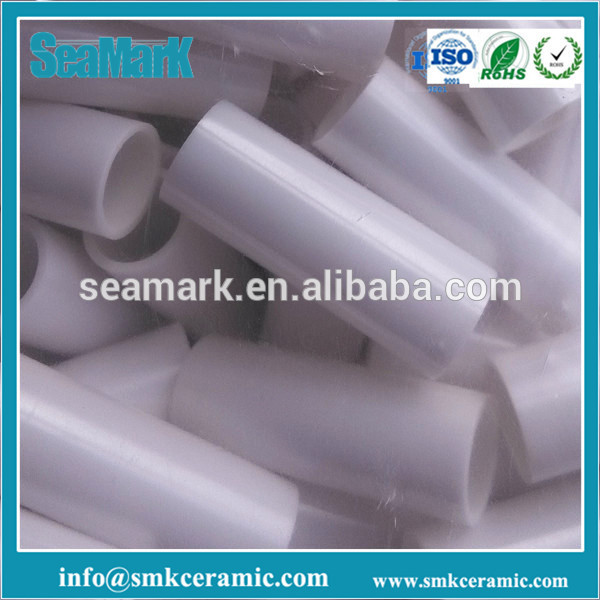

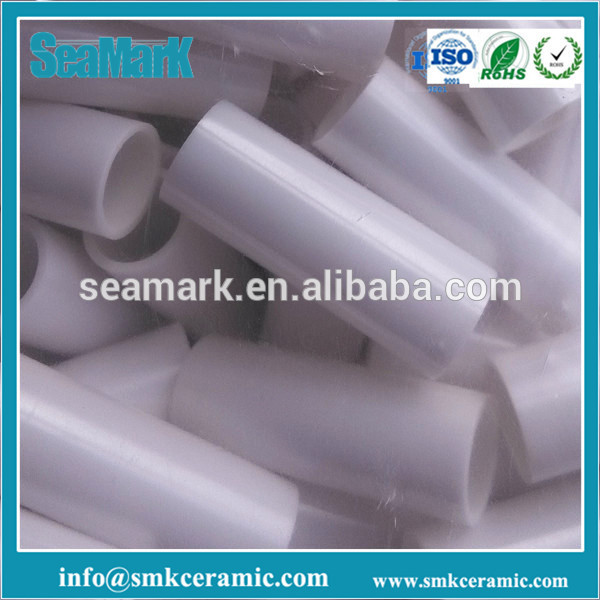

High fracture zirconia ceramic shaft sleeves for micropump Description of ceramic shaft sleeves.

Zirconia ceramic material introduction. 1.High density 2.High corrosion resistance. 3.High strength and high fracture toughness. 4.High hardness and excellent wear resistance. 5.High temperature resistance ability. 6.Low thermal conductivity. Technial datasheet for zirconia ceramic material.

Zirconia ceramic material introduction. 1.High density 2.High corrosion resistance. 3.High strength and high fracture toughness. 4.High hardness and excellent wear resistance. 5.High temperature resistance ability. 6.Low thermal conductivity. Technial datasheet for zirconia ceramic material.

Stock specification of zirconia ceramic shaft sleeves zirconia ceramic shaft sleeves tolerance of OD can reached 0.002mm, ID can reached 0.01mm. Our normal zirconia ceramic shaft sleeves diameter from 1mm to 15mm, the max diameter can reached 100mm. the zirconia ceramic rod normal length within 100mm. but we also can provide 1000mm length ceramic rods. High strength pump zirconia ceramic shaft sleeves with high wear resistance, its working life almost 10 times than cemented carbide.

About us. Suzhou Seamark Fine Ceramics Co., Ltd, treats honest and trustworthiness as business concept to treat perfect quality ,best price and punctual delivery as business guidelines, treats customer fist, good faith compliance, high quality and efficiency and the pursuit of excellence as the quality policy. We welcome friends from all over the world .We believe that our cooperation must be mutually beneficial win-win situation. Our service: The stable and experience team can provide professional service. Our Advantage: 1.Best quality

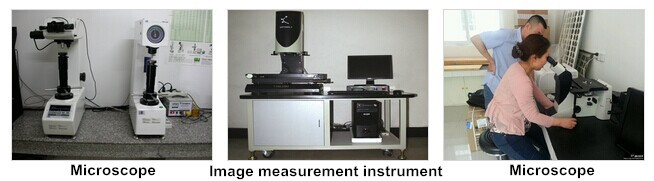

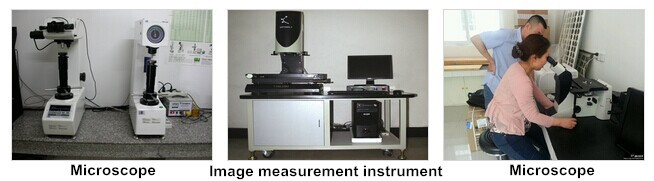

2.Competitive price and on time delivery 3.Professinal service 4. Export the bearings to the whole world with high reputation 5. Strict Quality Control 6. Experienced sales and Engineers Quality Assurance: All products are strictly inspected by Inspectors. Submit each order status via picture every week. Full-set quality control tracking system.

Choose Seamark Ceramic, we are now able to offer following services: 1. Before sales service: we will reply all your questions or inquiry in time, if you need some suggestion on your project, it will be our pleasure to do it. 2. In contract: our strict quality control is performed in every step of producing; we pay attention on every detail to ensure you are satisfied with our products and service. 3. After sales service: any questions, please let us know by email or phone, we will help you to deal with those problems. We can supply the products according to customer's drawings, samples and performance requirement. If you need any further information, please do not hesitate to contact us .or you can visit our website. www.smkceramic.com Suzhou Seamark Fine Ceramics Co., Ltd Ms.Linda Huang Tel: +86 512 66255075 Fax: +86 512 66255030 Mob: +86 18550512237

Choose Seamark Ceramic, we are now able to offer following services: 1. Before sales service: we will reply all your questions or inquiry in time, if you need some suggestion on your project, it will be our pleasure to do it. 2. In contract: our strict quality control is performed in every step of producing; we pay attention on every detail to ensure you are satisfied with our products and service. 3. After sales service: any questions, please let us know by email or phone, we will help you to deal with those problems. We can supply the products according to customer's drawings, samples and performance requirement. If you need any further information, please do not hesitate to contact us .or you can visit our website. www.smkceramic.com Suzhou Seamark Fine Ceramics Co., Ltd Ms.Linda Huang Tel: +86 512 66255075 Fax: +86 512 66255030 Mob: +86 18550512237

| Product Name: | High fracture zirconia ceramic shaft sleeves for micropump |

| Size: | According to drawings(Customized) |

| Material: | zirconia ceramics |

| Accuracy: | Accuracy Of Machining:+/-0.01mm |

| Accuracy Of Grinding:+/-0.005mm | |

| Surface Roughness:Ra0.02 | |

| Parallelism:0.01mm | |

| Verticality:+/-0.005mm | |

| Concentricity:0.01mm | |

| Application: | Pump motor, Car industrial, Chemical, Mechanical Equipment, etc. |

| Drawing: | JPEG, PDF, CAD, IGS Accepted |

| services: | Quality assurance, on time delivery. comparative price. |

| Design: | Design and improvement to meet your individual demands. |

| Production: | High precision production, high standard and strict requirement. |

| Quality: | ISO9001 Quality System Management Assurance |

| Products: | Custom made service for you. |

| Payment: | T/T,30% Prepaid,70%before shipment. |

| Logistics: | Air Express or Sea shipment. |

| Customer Service: | 24-hours standby, Critical listening your every suggestion or demand and feedback ASAP. |

Zirconia ceramic material introduction. 1.High density 2.High corrosion resistance. 3.High strength and high fracture toughness. 4.High hardness and excellent wear resistance. 5.High temperature resistance ability. 6.Low thermal conductivity. Technial datasheet for zirconia ceramic material.

Zirconia ceramic material introduction. 1.High density 2.High corrosion resistance. 3.High strength and high fracture toughness. 4.High hardness and excellent wear resistance. 5.High temperature resistance ability. 6.Low thermal conductivity. Technial datasheet for zirconia ceramic material. | Property | Density | g/cm3 | 6 |

| sintering temperature | °C | 1600 | |

| Weibull Modulus | m | 23 | |

| Flexural Strength | HV0.5 | 1300 | |

| Compressive Strength | Mpa | 1000 | |

| physical properties | fracture toughness | Map.m3/2 | 42163 |

| Compressive Strength | Mpa | 3000 | |

| Modulus of Elasticity | GPa | 200 | |

| Impact Resistance | MPa.m1/2 | 8 | |

| Thermal performance | Thermal expansion | X10-6/K | 10 |

| Heat resistance impact force | T(°C) | 360 | |

| Thermal Conductivity | W/mk | <2 | |

| Thermal Shock resistance | ΔT°C | 270 | |

| Highest Application Temperature | °C | 1000 | |

| Electrical characteristics | Volume Resistivity at 20°C | Ωcm | >10^12 |

| Dielectric breakdown strength | KV/mm | - | |

| Dielectric constant | 100MHz(E) | - | |

| 1 MHZ dielectric loss Angle at 20°C | tanδ | - |

| Φ1.91*36.8mm | 10000set |

| Φ19.23*15.5mm | |

| Φ1.91*52mm | 40000set |

| Φ3*Φ1.923*15.5mm | |

| Φ2.39*55mm | 9000set |

| Φ3.2*Φ2.4*15.5mm | |

| Φ2.485*19.2mm | 20000set |

| Φ3.9*Φ2.5*10mm | |

| Φ1.98*16.8mm | 20000set |

| Φ3.9*Φ2*8mm | |

| Φ3.16*46mm | 4000pcs |

| Φ1.57*32mm | 1000pcs |

2.Competitive price and on time delivery 3.Professinal service 4. Export the bearings to the whole world with high reputation 5. Strict Quality Control 6. Experienced sales and Engineers Quality Assurance: All products are strictly inspected by Inspectors. Submit each order status via picture every week. Full-set quality control tracking system.

Choose Seamark Ceramic, we are now able to offer following services: 1. Before sales service: we will reply all your questions or inquiry in time, if you need some suggestion on your project, it will be our pleasure to do it. 2. In contract: our strict quality control is performed in every step of producing; we pay attention on every detail to ensure you are satisfied with our products and service. 3. After sales service: any questions, please let us know by email or phone, we will help you to deal with those problems. We can supply the products according to customer's drawings, samples and performance requirement. If you need any further information, please do not hesitate to contact us .or you can visit our website. www.smkceramic.com Suzhou Seamark Fine Ceramics Co., Ltd Ms.Linda Huang Tel: +86 512 66255075 Fax: +86 512 66255030 Mob: +86 18550512237

Choose Seamark Ceramic, we are now able to offer following services: 1. Before sales service: we will reply all your questions or inquiry in time, if you need some suggestion on your project, it will be our pleasure to do it. 2. In contract: our strict quality control is performed in every step of producing; we pay attention on every detail to ensure you are satisfied with our products and service. 3. After sales service: any questions, please let us know by email or phone, we will help you to deal with those problems. We can supply the products according to customer's drawings, samples and performance requirement. If you need any further information, please do not hesitate to contact us .or you can visit our website. www.smkceramic.com Suzhou Seamark Fine Ceramics Co., Ltd Ms.Linda Huang Tel: +86 512 66255075 Fax: +86 512 66255030 Mob: +86 18550512237 Send your inquiry to this supplier

Send Inquiry