1 / 5

High efficiency powder air classifier machine

Get Latest Price

Send Inquiry

| Model No. : | AF |

|---|---|

| Brand Name : | Jinghua |

Weifang Jinghua Powder Engineering Equipment Co., Ltd.

You might also like

Product description

Product Description

AF Air classifier

Description

The feed material enters the classifier with the main air flow which can be a highly cost-effective process option if integrated into a system with direct pneumatic feed. The classifying wheel speed can be steplessly adjusted by means of a frequency converter.By altering the classifying wheel speed,the particle size can be easily adjusted even during operation.Fine particles whose size is below the set cut point are transported through the rotor blades along with the classifying air,are then discharged via the fines discharge in the main air flow,and finally collected in a suitable filter.Coarse particles are rejected by the classifying wheel and are discharged via the coarse material discharge.Before being discharged,the coarse material is rinsed intensively in a spiral flow taken from the secondary air stream to remove any last fine powder,this step improves the precision of cut and increases the fine powder yield.

The dry classification is achieved based on the size,shape and density of particle,the classifier can be used with every kind of grinder in a closed negative operation,the integration of size reduction and classification reduce the production cost,and the flammable and explosive,oxidizable materials can be classified with inert gas shielding.

Feature

1.Optimized impeller structure design of vertical single rotor and horizontal multi-rotor,which can be composed closed circuit system connected with ball mill,using multi-wheel technology to improve product fineness and increase capacity.

2.Classification efficiency can be 60-90%, d97=2.0 ~150um is adjustable.

3.Designed to the infinitely variable speeds and wear resistant,easy clean and change varieties of product.

4.Negative operation is free from dust,low noise and vibration.

5.Eliminate the oversize and superfine particle existing in product,free of particle entrainment.

6.In conjuction with several classifiers,get different particle sizes.

Application

Mineral:calcium carbonate,kaolin,quartz,talc,mica,zircon sand,feldspar.

Chemical,metallurgy,abrasive,ceramic,medicine,pesticide,food,health products,new material,refractory material,etc. Technical Parameter Single impeller: Multi-impeller:

Multi-impeller:

Process Flow Chart

Process Flow Chart  1.Feeding system 2. 1st Air classifier 3. 2nd Air classifier 4. 3rd Air classifier 5. Cyclone collector

1.Feeding system 2. 1st Air classifier 3. 2nd Air classifier 4. 3rd Air classifier 5. Cyclone collector

6. Dust collector 7. Draught fan 8. Electrical control system

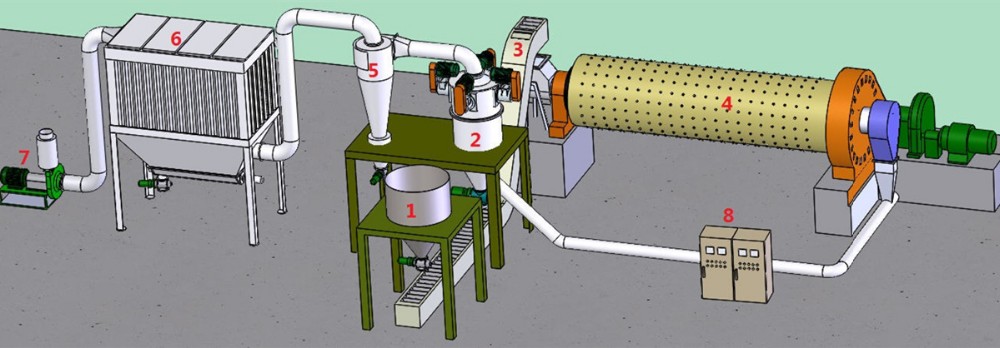

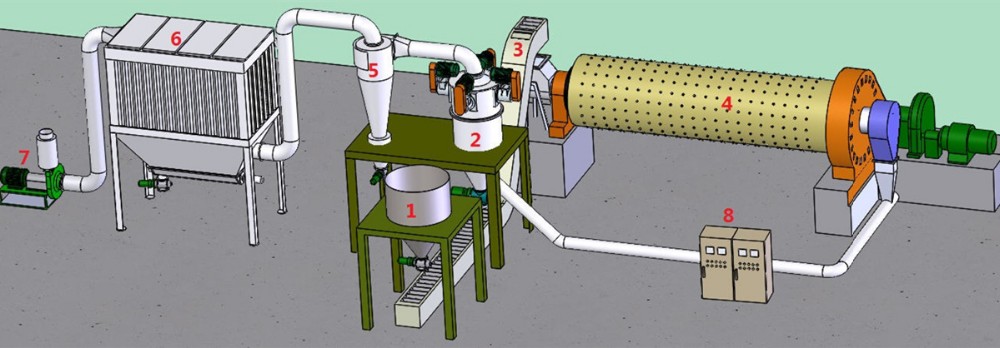

1.Silo 2. Air classifier 3.Belt conveyor 4.Ball mill 5.Cyclone collector

1.Silo 2. Air classifier 3.Belt conveyor 4.Ball mill 5.Cyclone collector

6.Dust collector 7.Draught fan 8.Electrical control system

Kinds of wheel

Our Service

Our Service

Pre-Sales Service 1.To provide technical advisory services,for free testing and provide 1:1 technical parameter for the customers.

Pre-Sales Service 1.To provide technical advisory services,for free testing and provide 1:1 technical parameter for the customers.

2.Provide technical data,equipment floor diagram,space diagram, installation detailed drawing and electric system drawing,etc.

After-Sales Service

1.We shall offer equipment schedule,equipment layout,foundation drawing etc.

2.Provide installation guide,commissioning and technical training,assure production operation on schedule and design requirement.

Our Company Established in 1996,it is working on research and development of powder engineering equipments and technology, and it has become one of main suppliers of superfine powder engineering equipment,actived in the international powder Processing field,Many products have reached international leading level.

It has a modern pilot plant equipped with classic complete equipments as well as lots of advanced test instruments including advanced particle size laser analyser, and can offer 1:1 industrial test for fine grinding and classifying materials before purchasement for customer.

Technical support and service:

International leading optimum solution.

Grinding and classifying test

Design,manufacture,turn-key project

Installation and commissioning,technical support,operator training,maintenance

Contact Us

Description

The feed material enters the classifier with the main air flow which can be a highly cost-effective process option if integrated into a system with direct pneumatic feed. The classifying wheel speed can be steplessly adjusted by means of a frequency converter.By altering the classifying wheel speed,the particle size can be easily adjusted even during operation.Fine particles whose size is below the set cut point are transported through the rotor blades along with the classifying air,are then discharged via the fines discharge in the main air flow,and finally collected in a suitable filter.Coarse particles are rejected by the classifying wheel and are discharged via the coarse material discharge.Before being discharged,the coarse material is rinsed intensively in a spiral flow taken from the secondary air stream to remove any last fine powder,this step improves the precision of cut and increases the fine powder yield.

The dry classification is achieved based on the size,shape and density of particle,the classifier can be used with every kind of grinder in a closed negative operation,the integration of size reduction and classification reduce the production cost,and the flammable and explosive,oxidizable materials can be classified with inert gas shielding.

Feature

1.Optimized impeller structure design of vertical single rotor and horizontal multi-rotor,which can be composed closed circuit system connected with ball mill,using multi-wheel technology to improve product fineness and increase capacity.

2.Classification efficiency can be 60-90%, d97=2.0 ~150um is adjustable.

3.Designed to the infinitely variable speeds and wear resistant,easy clean and change varieties of product.

4.Negative operation is free from dust,low noise and vibration.

5.Eliminate the oversize and superfine particle existing in product,free of particle entrainment.

6.In conjuction with several classifiers,get different particle sizes.

Application

Mineral:calcium carbonate,kaolin,quartz,talc,mica,zircon sand,feldspar.

Chemical,metallurgy,abrasive,ceramic,medicine,pesticide,food,health products,new material,refractory material,etc. Technical Parameter Single impeller:

Multi-impeller:

Multi-impeller:  Process Flow Chart

Process Flow Chart  1.Feeding system 2. 1st Air classifier 3. 2nd Air classifier 4. 3rd Air classifier 5. Cyclone collector

1.Feeding system 2. 1st Air classifier 3. 2nd Air classifier 4. 3rd Air classifier 5. Cyclone collector6. Dust collector 7. Draught fan 8. Electrical control system

1.Silo 2. Air classifier 3.Belt conveyor 4.Ball mill 5.Cyclone collector

1.Silo 2. Air classifier 3.Belt conveyor 4.Ball mill 5.Cyclone collector6.Dust collector 7.Draught fan 8.Electrical control system

Kinds of wheel

Our Service

Our Service

Pre-Sales Service 1.To provide technical advisory services,for free testing and provide 1:1 technical parameter for the customers.

Pre-Sales Service 1.To provide technical advisory services,for free testing and provide 1:1 technical parameter for the customers.2.Provide technical data,equipment floor diagram,space diagram, installation detailed drawing and electric system drawing,etc.

After-Sales Service

1.We shall offer equipment schedule,equipment layout,foundation drawing etc.

2.Provide installation guide,commissioning and technical training,assure production operation on schedule and design requirement.

Our Company Established in 1996,it is working on research and development of powder engineering equipments and technology, and it has become one of main suppliers of superfine powder engineering equipment,actived in the international powder Processing field,Many products have reached international leading level.

It has a modern pilot plant equipped with classic complete equipments as well as lots of advanced test instruments including advanced particle size laser analyser, and can offer 1:1 industrial test for fine grinding and classifying materials before purchasement for customer.

Technical support and service:

International leading optimum solution.

Grinding and classifying test

Design,manufacture,turn-key project

Installation and commissioning,technical support,operator training,maintenance

Contact Us

Send your inquiry to this supplier

Send Inquiry