1 / 1

High capacity PLA sheet extrusion line

$200000.00

≥1 Set/Sets

$195000.00

≥2 Set/Sets

Model:

- HBD-65

- HBD-75

| Model No. : | HBD-150 |

|---|---|

| Brand Name : | HAOBANG |

| place of origin : | China |

Product description

PLA biodegradable sheet project & machines

PLA polylactic acid/cornstarch-based biodegradable material is a new type of polyester bio-renewable and fully degradable material.

We supply the high capacity PLA sheet extrusion machine with professional Technics.

Product specifications and applications:

The thickness is 0.15-2 mm, and the width is mainly 600-2000mm (adjustable). Different color specifications can be made according to customer requirements. PLA polylactic acid degradable sheet is suitable for blister processing, and can also be made into various food packaging boxes, lunch boxes, plates, cards, tags, folders and envelopes, etc.

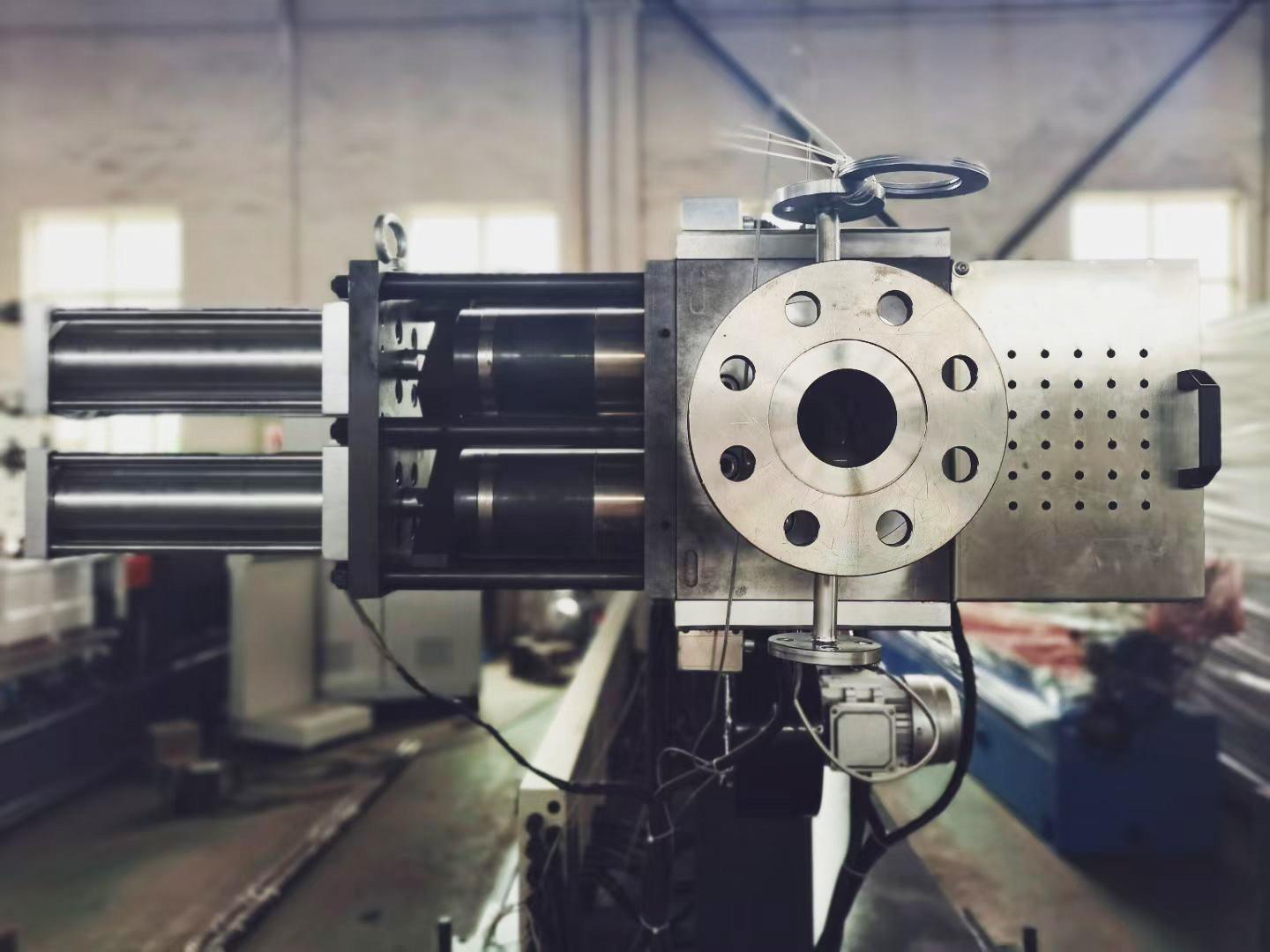

Machines need:The production line includes co-rotating twin-screw extruder, screen changer, melt metering pump, mould, calender, cooling bracket, trimming device, haul off, duplex winder, etc.

Features of PLA degradable sheet equipment:

The screw adopts a twin-screw design, which is specially designed for the melting of polylactic acid and corn starch. At the same time, it can be vented according to the particularity of the material. The horizontal three-roller calender is formed, and the temperature of the roller is adjusted by the mold temperature machine, to ensure that the product is free from paste and has a good surface color. Equipped with melt metering pump for quantitative extrusion, speed and pressure closed-loop control, so that the thickness of the sheet is uniform. The rollers are driven independently, and the linear speed of each roller is controlled synchronously. The whole machine adopts PLC control, the actual parameter setting, data calculation and feedback, alarm and other functions are automated

Processing flow:

PLA degradable sheet equipment production process principle: PLA material corn starch material → vacuum feeding → extruder (raw material melting and plasticization) → quick screen changer → melt metering pump → extrusion die extrusion Forming → Horizontal three-roll calender → Cooling conveying device → Edge trimming knife set → Haul off conveying → Tension winding machine

Equipment advantages:

1.Equipped with precision distributor, uniform layering, adjustable ratio of each layer, digital control precision.

2.The inclined and horizontal tablet pressing structure is more convenient for operation and maintenance.

3. The roller has independent power, the linear speed and the extruder speed are synchronously closed-loop controlled.

4. The whole machine adopts PLC control to realize automatic control of parameter setting, data calculation and feedback, alarm and other functions.

5.The electrical control system and operating procedures are designed and programmed by HAOBANG Machinery

Applications:

Send your inquiry to this supplier