1 / 4

High accuracy low-power Gear Reducers Crank Shaft Bearings

| Model No. : | robot reducer bearing |

|---|---|

| Brand Name : | ZXZ |

Shaoxing, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

High accuracy low-power Gear Reducers Crank Shaft Bearings

ZXZ Regard the R&D and innovation as the fundamental of a company, and provide the product exceeding the customer expectation. Digitized simulation software and static-dynamic simulation analyzation help to achieve the highly CAE; We also adopt nanoscale level of runout, ultra-precision measuring instruments of contour, etc. To meet the need of high precision bearings inspection; Digital controlled simulation test equipments of bearing performance can conduct fully simulation tests according to the situations Professional engineers keep creating, improving the production technology to improve machinery efficiency and product precision. Has built the Post-doctoral work station, provincial technology center and Enterprise Institute.

With the rapid development of equipment manufacturing industry, automation has been increasingly demanded, industrial robots gradually adopted in various industries. The harmonic reducer of industrial robots has characteristics of high speed ratio and high transmission torque. Harmonic reducer flexible bearings require high- precision, abrasion resistant, and anti-fatigue.

•Using high quality of ultra pure bearing steel and vacuum heat treatment process, strict control the hardness and microstructure of materials, to ensure flexible bearings maintain the stability of size and rotation accuracy, and fatigue resistance, which under a large deformation of working condition.

•Using high-precision CNC equipment and special processing technology, accuracy level of bearings can reach P2-class.

•Using nano-scale ultra high-precision measuring instruments to measure the profile and geometric tolerances of major working surface, which ensure the accuracy of design requirements.

Apply to Robot harmonic reducer:

With the rapid development of equipment manufacturing industry, automation has been increasingly demanded, industrial robots gradually adopted in various industries. The harmonic reducer of industrial robots has characteristics of high speed ratio and high transmission torque. Harmonic reducer flexible bearings require high- precision, abrasion resistant, and anti-fatigue.

·Using high quality of ultra pure bearing steel and vacuum heat treatment process, strict control the hardness and microstructure of materials, to ensure flexible bearings maintain the stability of size and rotation accuracy, and fatigue resistance, which under a large deformation of working condition.

·Using high-precision CNC equipment and special processing technology, accuracy level of bearings can reach P2-class.

·Using nano-scale ultra high-precision measuring instruments to measure the profile and geometric tolerances of major working surface, which ensure the accuracy of design requirements.

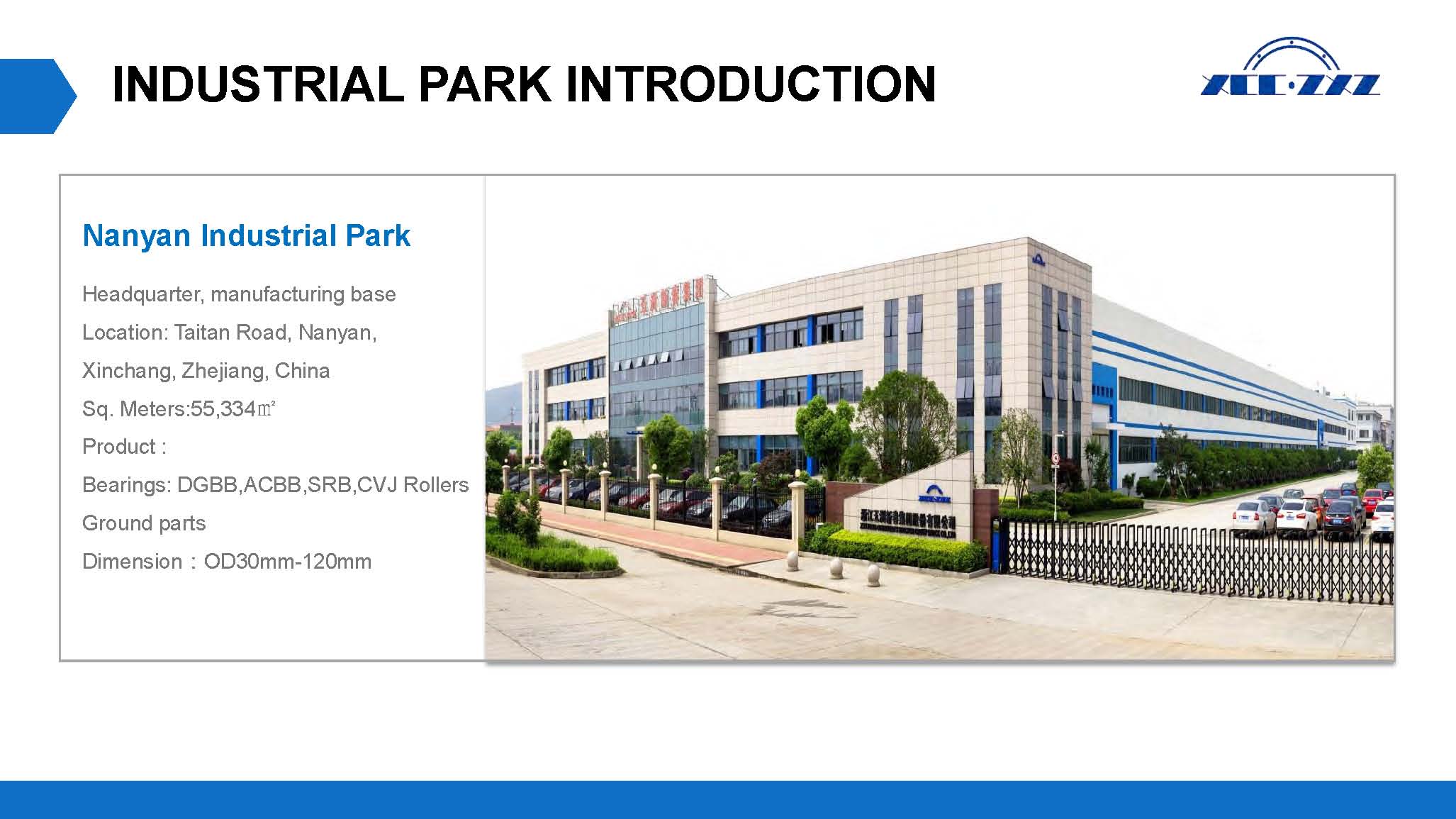

XCC Group is China listed group enterprise (stock code: 603667) with more than 10 subsidiaries, specialized in the fields of bearings, bearing parts and auto parts manufacturing.

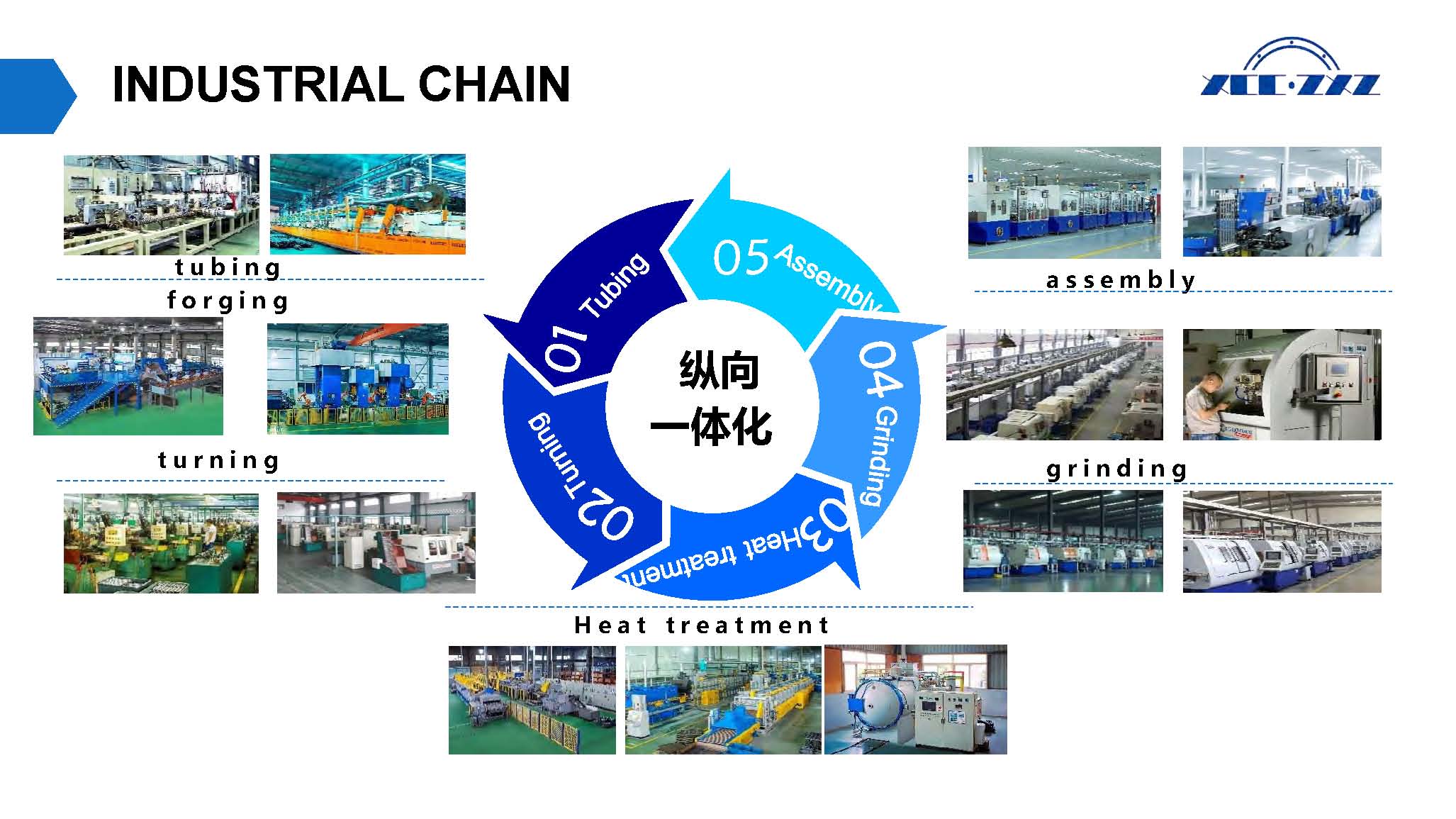

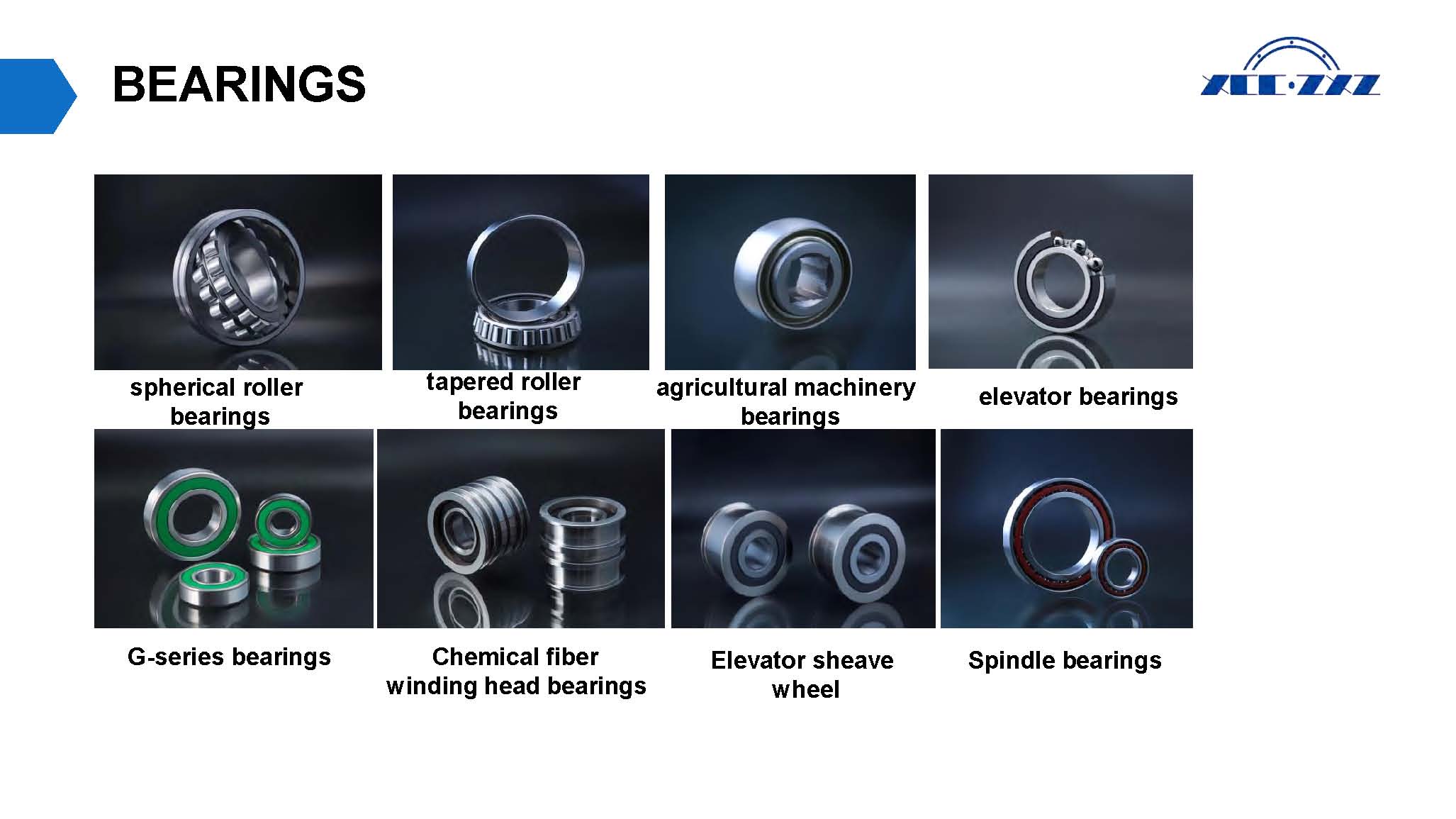

XCC has an integrated bearing production chain what combined with R&D, tubing, forging, turning, heat treating, grinding etc. Including auto alternator bearings,tension bearings, air-conditioner clutch bearings, water pump bearings, precision machine tool bearings, chemical fiber & textile machinery bearings, as well as whole series of standard and non-standard deep groove ball bearings etc with high precision, high speed, low noise and long life.

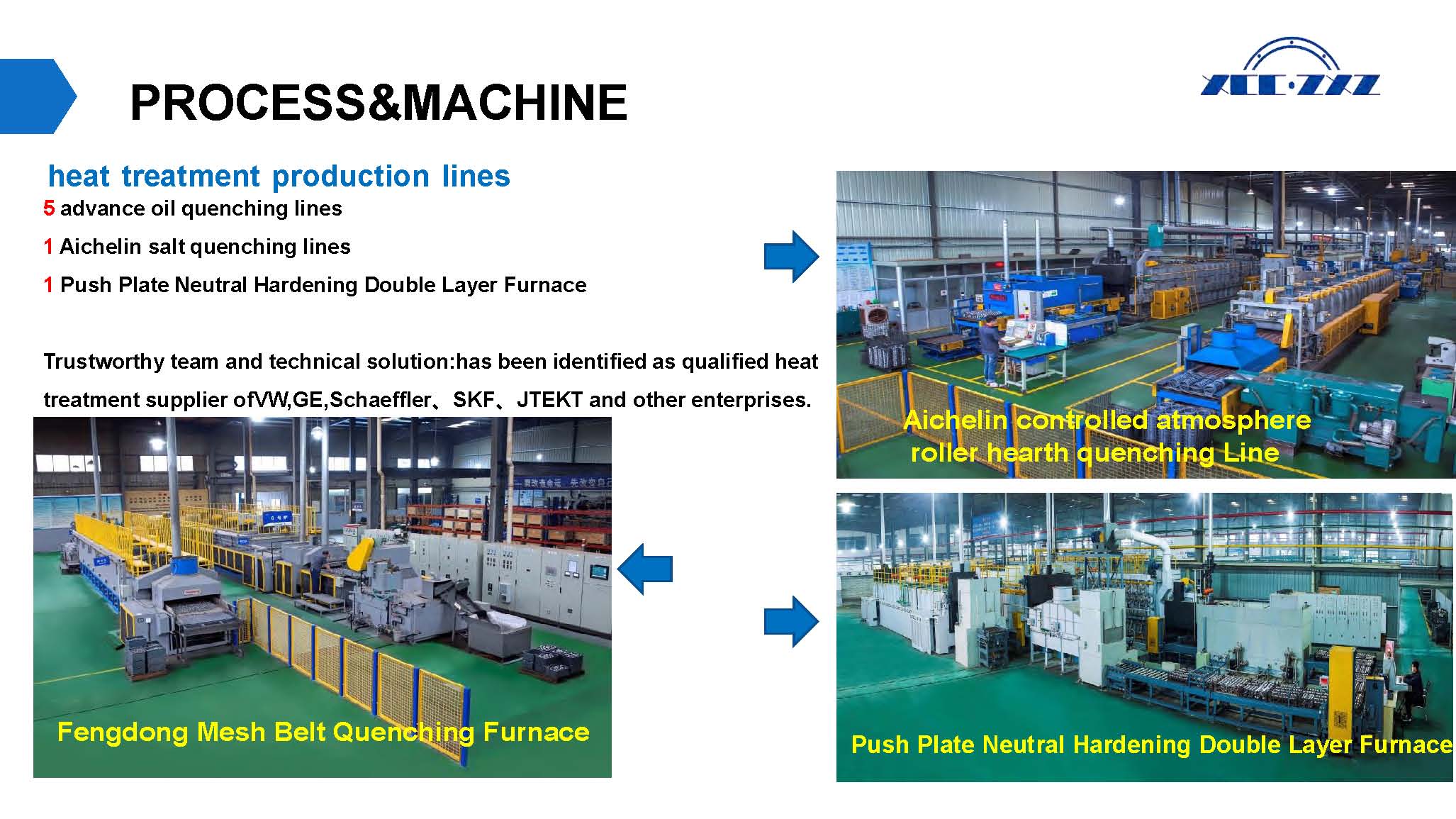

ZXZ build up entire bearing production line from steel tube, forging, turning, heat treatment to grinding and assembling after 10 years effort; high quality bearing rings which do heat treatment already provide for top 5 bearing manufacturer worldwide, production capacity reach 200 million sets annually; adopt full automatic CNC grinding and assembly line, benefit from big amount of advanced manufacturing equipment, ZXZ has ability to service for world class level customers.

XCC has been one most supplier of bearing rings for SCHAEFFLER,SKF,NSK,NTN, JTEKT,TIMKE..., and been a supplier of bearings used for BMW,NISSANS,NISSAN, and HYUNDAI... Tapered roller bearing supplier to DANA and FAG.

we also produce lot of special form shafts, wasters, thin wall rings, vanes for automotive OE customers.

Shaoxing, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier