Video

1 / 6

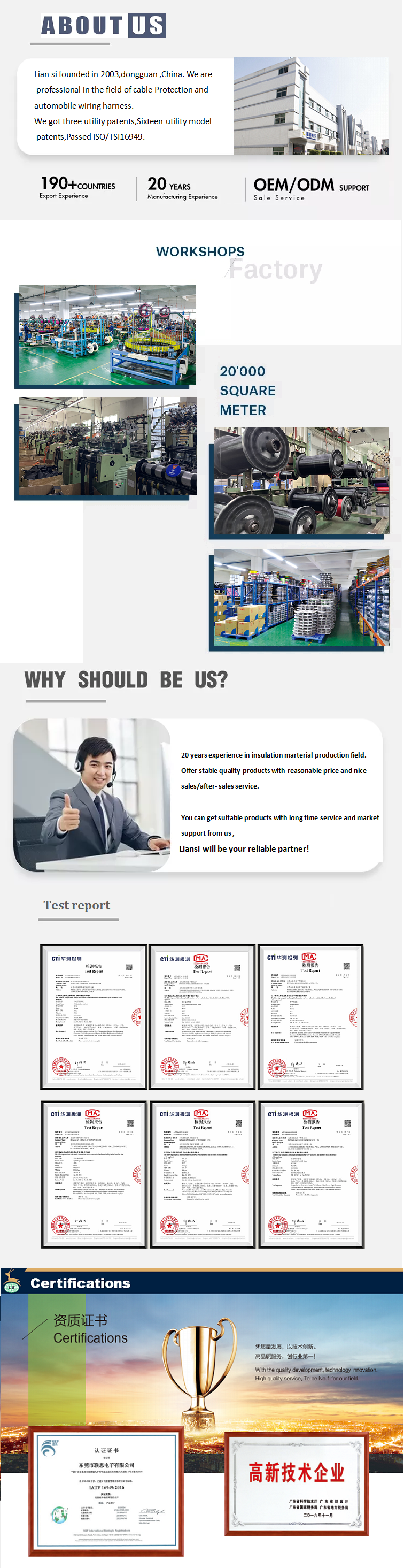

Green electrical insulation PE heat shrinkable tubing

$0.10

≥1000 Others

$0.09

≥1800 Others

$0.08

≥3000 Others

| Brand Name : | Ls |

|---|

Dongguan, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

Product description

Heat shrinkable tubes are commonly used to bundle and protect wires. They are made of a thermoplastic material that shrinks when exposed to heat, creating a tight and secure seal around the wires. Heat shrinkable tubes offer insulation, strain relief, and protection against abrasion, chemicals, and moisture.

When selecting a Heat Shrinkable Tube for bundling wires, consider the following factors:

1. Size: Choose a tube with an appropriate diameter to accommodate the size of the wire bundle. The tube should be large enough to fit over the wires but small enough to shrink tightly when heated.

2. Shrink ratio: Heat Shrink Tubes come in different shrink ratios, which indicate the percentage of shrinkage. Common shrink ratios include 2:1, 3:1, and 4:1. A higher shrink ratio provides a tighter seal.

3. Material: Heat Shrink tubing can be made of various materials, including polyolefin, PVC, and fluoropolymer. Consider the specific requirements of your application, such as temperature resistance, flexibility, and chemical resistance, to choose the appropriate material.

4. Operating temperature: Ensure that the heat shrinkable tube can withstand the operating temperature of the wires. It should have a higher temperature rating to prevent melting or deformation.

5. Color: Heat Shrinkable Tubes are available in different colors, which can help with wire identification and organization.

6. Adhesive-lined: Some heat shrinkable tubes have an adhesive lining that provides additional protection and a watertight seal. This can be beneficial in applications where moisture resistance is required.

When applying heat shrinkable tubes, use a heat gun or heat source to evenly heat the tube until it shrinks tightly around the wire bundle. Ensure that the tube is properly positioned and sealed to provide maximum protection.

Technical parameters

| Initial shrink temperature | 70ºC |

| Minimum full shrink temperature | 125ºC |

| Operating temperature | -45ºC-135ºC |

| Fire rating | Outer layer flame retardant,anti-ultraviolet radiation |

| Certification | ROHS,UL |

| Shrink Ratio | 3:1 ,4:1 |

|

||||||||

|

Specification

|

|

|

|||||

|

|

|

|||||

Video

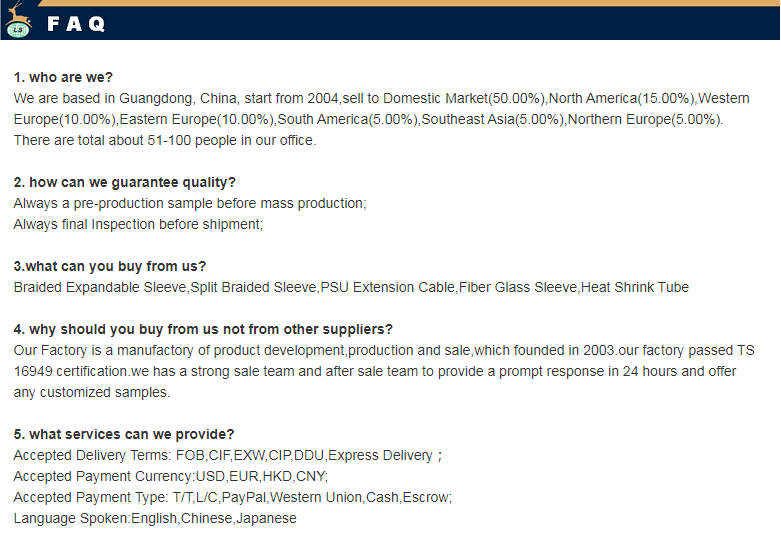

Dongguan, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier