1 / 5

Gold Smelter Automatic Chamber Hydraulic Filter Press

$3500.00

≥1000 Set/Sets

productivity:

- 100sets/month

Model:

- XJ50/800-30U

Send Inquiry

| Model No. : | XJ50/800-30U |

|---|---|

| Brand Name : | SHEN HONG FA |

| Applicable industry : | Manufacturing Plant,Food &Amp; Beverage Factory,Retail,Construction Works,Energy &Amp; Mining |

More

4yrs

Shenzhen, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- Gold Supplier

- Platform Certification

Shenzhen Hongfa Environmental Protection Equipment CO., LTD

You might also like

Product description

Product Introduction

Overview

Cast iron filter press is widely used in the solid-liquid industry, which is used in oil plants (lubricating oil, mechanical oil, diesel oil, waste oil, glycerin, coal tar), chemical industry (chemical fertilizer, dye, pigment, electrolytic manganese), fine chemical industry (paohua alkali, sodium silicate, sodium silicate), water treatment and other different industries. The preferred production process of the spherical ink filter press is sand casting, which has the advantages of high strength, toughness and plastic comprehensive performance, good wear resistance, and good casting process performance. After heat treatment, the spheroidal ink filter plate has the characteristics of high strength, high filtration pressure and high temperature resistance, and the prospect is very broad.

Product description

Our company produces various types of box and plate frame mechanical filter presses, hyd raulic filter presses, diaphragm filter presses, automatic filter presses, quick-opening filter pr esses, and filter press accessories, with reliable quality and complete specifications

1. Specifications : Types of 200, 380, 500, 700, 870, 1000, 1250, 1500, 2000, and various special-shaped filter plates and filter presses.

2.The filtering area is up to 2000m

3. Filter plate material: stainless steel, cast iron, rubber, reinforced polypropylene, glass fiber with high temperature resistance, pp-30 elastomer membrane plate.

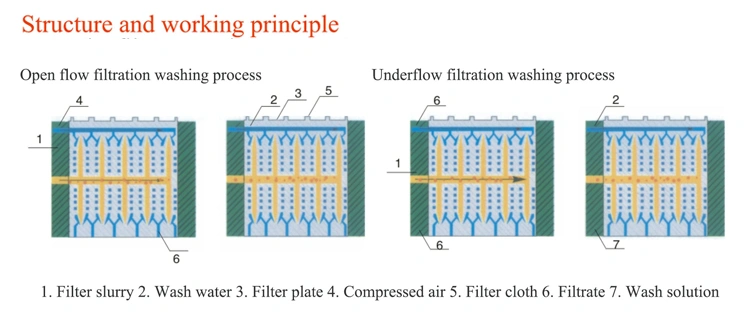

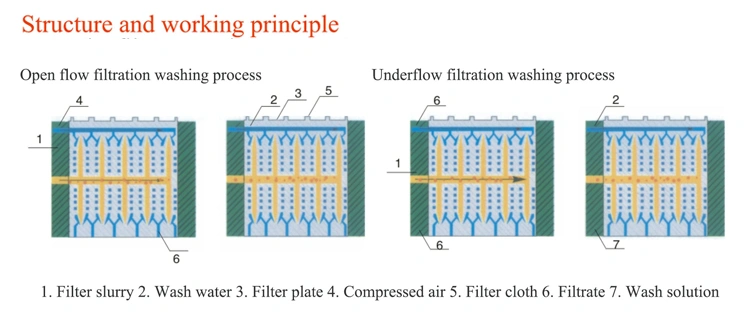

4. Liquid flow forms are open flow, dark flow, washable, non-washable, medium feed, corner feed, upper and middle feed and other forms.

5. Filter plate compąction methods are: manual sçrew compaction, electro-mechanical com paction fluid, and hydraulic cylinder compaction. For special requirements of the filter press can be resolved separately.

6. The whole maçhine doęs not include material infusion pumps

and filter cloths. If nece ssary supplies can be specified in the contract.

and filter cloths. If nece ssary supplies can be specified in the contract.

7. According to the special requirements of customers, our company can produce non standard models and products suitable for your needs.

8. If technical data changes due to model improvements, the actual size at the time of ordering shall prevail.

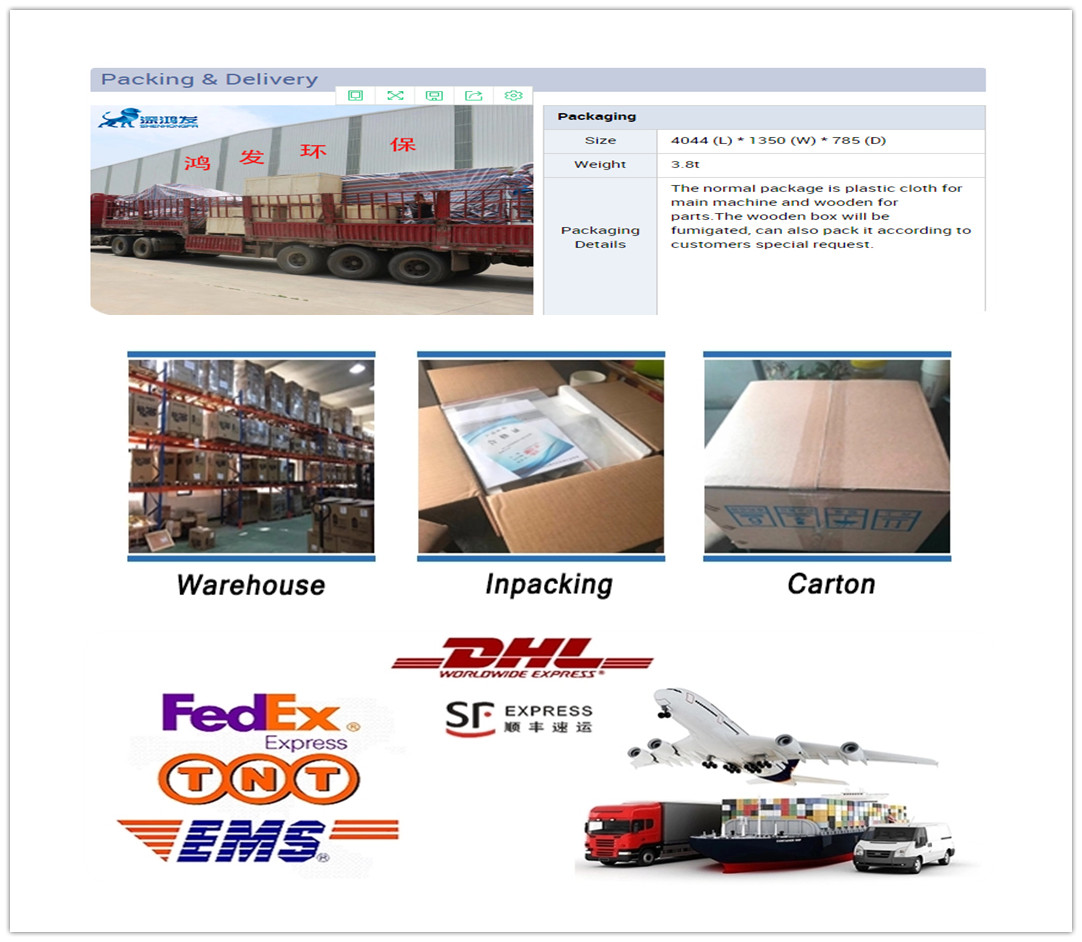

Packing & Shipping

FAQ

Q1: What's your business range?

A: We manufacture pH/ORP/EC/DO/Chlorine/Turbinity meter and provide dosing pump, diaphragm pump, dosing system, pressure instrument, flow meter, level meter, dosing system and so on.

Q2: How about the quality of the managements?

A: We have a complete quality control system, all of our products will be fully pre-inspection by QC departments before shipping to you. We have the certification of ISO, CE we could send the certification test of our company to you.

Q3: Can you offer OEM or design services?

A: Yes, we have our own design department and production tools. We can make OEM products according to your requirements.

Q4: What are your terms of payment and delivery time?

A: We could accept T/T, Paypal, Western Union, Credit Assurance. Generally, we will arrange the shipment within 7 days after received payment.

Q5: How about warranty?

A: 12 months warranty.

More information please contact us, we will provide the timely feedback!

4yrs

Shenzhen, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier

Send Inquiry