Video

1 / 4

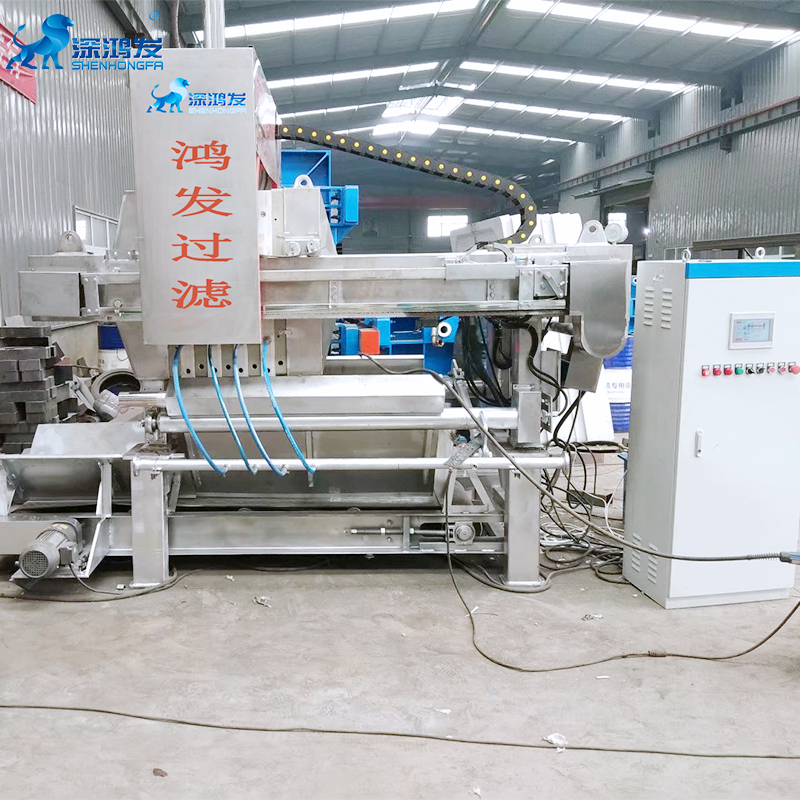

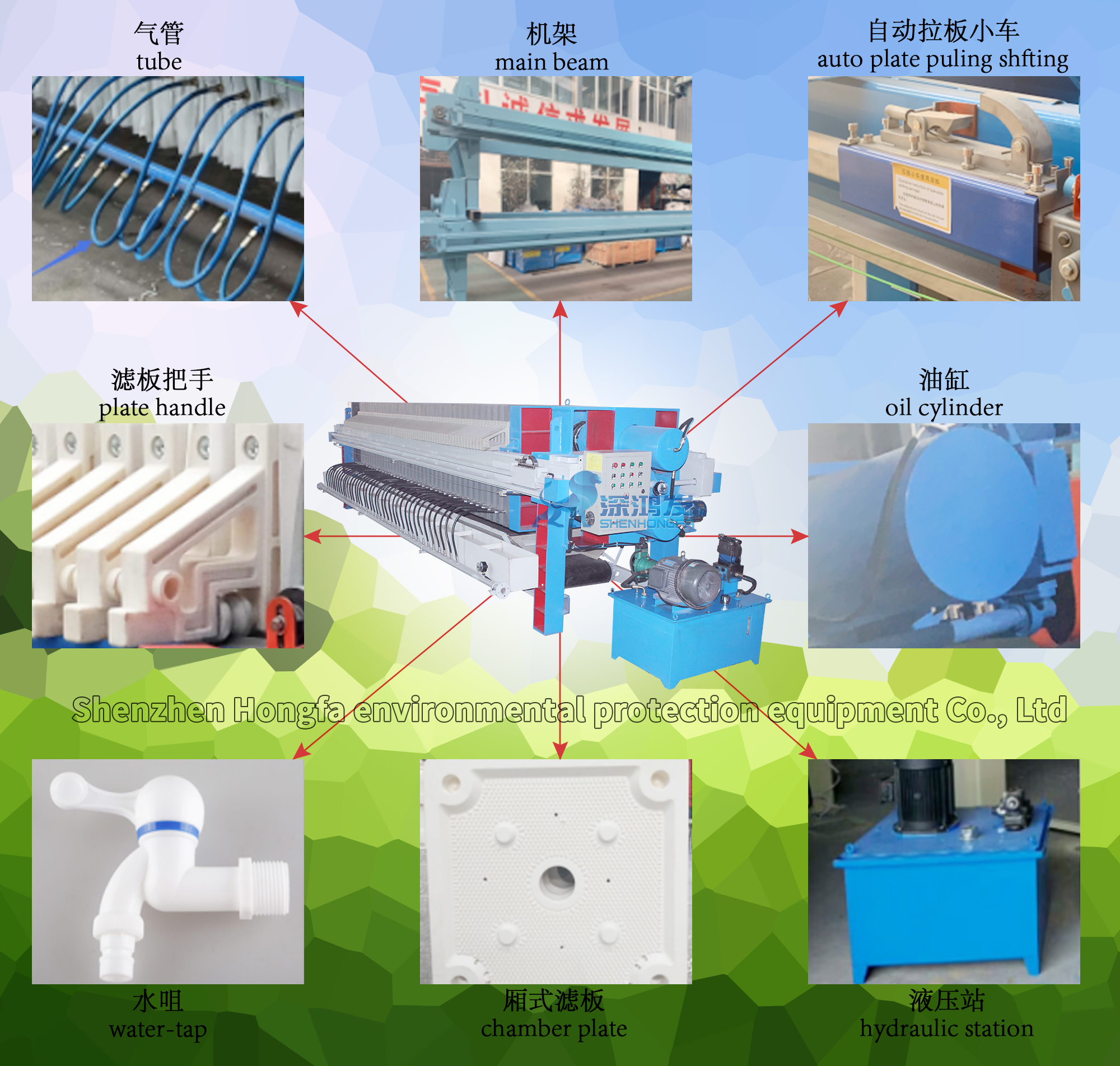

Cast Iron large chamber filter press

productivity:

- 300sets/month

Model:

- XMZ100/1000-30U

| Model No. : | XMZ100/1000-30U |

|---|---|

| Brand Name : | Shenhongfa |

| Applicable industry : | Other,Manufacturing Plant,Construction Works,Food &Amp; Beverage Factory,Energy &Amp; Mining |

Shenzhen, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- Gold Supplier

- Platform Certification

Product description

Abstract

Nowadays, the pollution of the environment is becoming more and more serious, not only the environment is polluted, the water source is also gradually polluted, how to treat sewage has been a major problem to be solved in our country, filter press is essential machinery in the process of sewage treatment, which cast iron filter press is very popular with customers, what is that cast iron filter press? How to maintain cast iron filter press?

What is the cast iron filter press

Cast iron filter press is made of cast iron or ductile iron precision casting. It has the characteristics of high strength of filter plate, large filtration pressure, high temperature resistance, fast filtration speed, low water of filter cake, fast discharge and long service life. Suitable for high viscosity, high temperature, require low moisture content of ceramic industry, petrochemical, oil, mechanical oil decolorization and other products filtration.

Three, how to maintain the cast iron filter press

1, the normal commissioning of the filter press can feed work, each shift before work to the whole machine for a comprehensive inspection. Mechanical pressing transmission parts and reducer must be added sufficient lubricating oil; Hydraulic pressure check the oil storage capacity of the tank and the working pressure of the hydraulic station. The hydraulic oil is generally replaced once a year, and the hydraulic system should be comprehensively cleaned during the replacement. The working pressure of the hydraulic station is less than the high working pressure of the cylinder, but it should not be lower than the allowable value of the filtration pressure.2. It is forbidden to start the machine when the filter plate is less than the specified number, so as not to damage the parts. Check the arrangement of the filter plate before feeding, and the press cloth should not be folded to prevent large leakage; After unloading the cake, the filter plate must be tightly arranged.

3, when everything is normal, can press the filter plate pressure filtration, filtration pressure and filtration temperature must be within the specified range, filtration pressure is too high will cause leakage, filtration temperature is too high plastic filter plate deformation, feeding suspension to uniform concentration. There shall be no mixed things; After unloading the cake, the press cloth and the filter plate must be washed, and the residue is not allowed to stick in the sealing surface or feed channel, otherwise it will affect the smooth feed and the tightness of the filter plate, which will result in the unbalanced pressure on both sides of the filter plate, resulting in the deformation and damage of the filter plate.

4, the choice of filter cloth must conform to the requirements of the propeller of filtration technology, should be shrunk before new filter cloth production, the hole diameter should be less than the filter plate aperture, the matching filter plate holes and hole of the plate should be relatively concentric, Jane should feed opening cloth tiejin compared.in addition, otherwise it will cause, filter, filter rate is low, cloth tube rupture, short of filtering the expected goal.

5. In the early stage of the filter press, the filter is cloudy, and the filtrate will become clear when a layer of cake is formed on the filter cloth. If the filtrate is always cloudy or clear, the press cloth may be damaged or the cloth hole deviates from the plate hole. At this time, the valve should be closed or the feed should be stopped to replace the press cloth. A small amount of leakage caused by cloth capillarity is allowed between the filter plates.6, when moving the filter plate, the force should be uniform and appropriate, not collision, fall, so as to avoid damage to the sealing surface and filter wrench. The press cloth will harden and deteriorate in performance after being used for a period of time. Therefore, regular inspection is needed. If the filtering rate is affected by changes, neutralization and cleaning with weak acid and base of corresponding low concentration can be used to restore the function of the press cloth.

7. The slurry, lotion or compressed air valve must be opened according to the operating procedure, and cannot be opened at the same time. The compressed air pressure cannot exceed the filtration pressure when the diaphragm is squeezed.

The above is a brief introduction of cast iron filter press. The emergence of cast iron filter press has made a great contribution to the national sewage treatment problem, but no matter how good the machinery is, we should also pay attention to its maintenance, so that it can be more efficient and convenient to use.

Welcome to SHENHONGFA

As a professional filter press manufacturer with more than ten years of experience, Shenzhen Hongfa

Video

Shenzhen, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier