1 / 5

Galvanized Steel Sheet Cold Roller Forming Machine

| Model No. : | ZY |

|---|---|

| Brand Name : | ZHIYE |

| Tile Type : | Colored Steel |

Cangzhou, Hebei, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Organization

- Service

- Trade Company

- OEM service

- Platform Certification

- Video

Product description

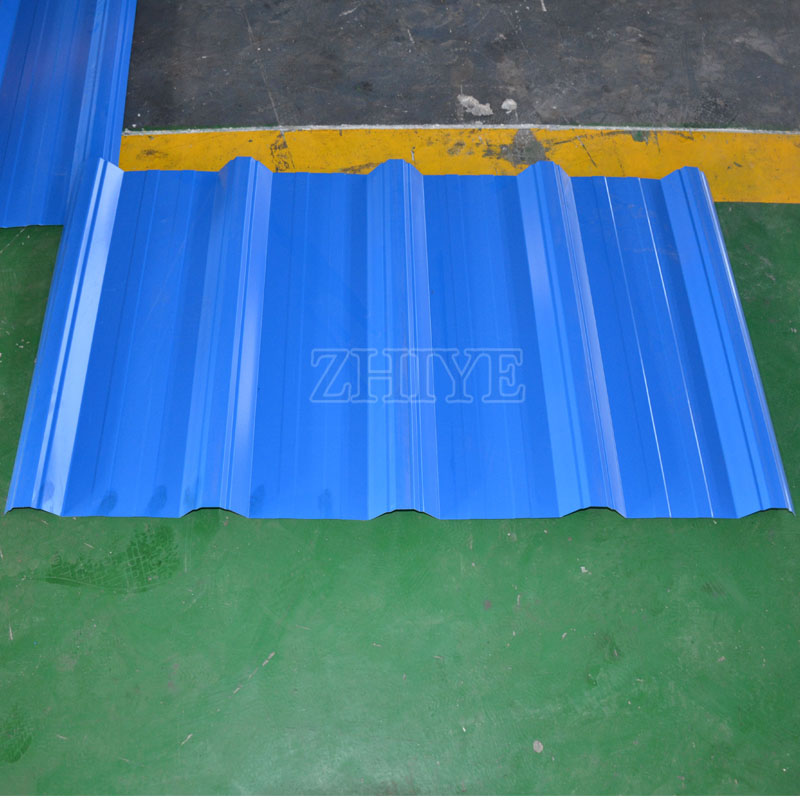

Galvanized Steel Sheet Cold Roller Forming Machine

General information for the Galvanized Steel Sheet Cold Roller Forming Machine

The tiles produced by Galvanized Steel Sheet Cold Roller Forming Machine are widely used in all kinds of factories, houses, warehouses and simple steel shed, and with beautiful appearance, high efficiency and reliable working.It consists of feeding platform, main molding core, shearing mechanism, hydraulic station, computer control cabinet, high precision counter and so on.Our main machine is Trapezoidal Roof Panel Roll Forming Machine,Glazed Roofing Tile Roll Forming Line,Roof Ridge Cap Production Line,C/u/z Purlin Roller Former Machine,Roller Door Panel Rolling Forming Machine,Floor Decking Panel Rolling Forming Machine,Downpipe Rain Gutter Roll Forming Machine,Light Steel Frame Cold Roll Forming Machine,Double Layer Roof Sheet Roll Forming Machine,Sandwich Panel Wall Roof Roll Forming Machine.

1.The Parameters of the Galvanized Steel Sheet Cold Roller Forming Machine

|

1 |

Processing Material |

PPGI;GI |

|

2 |

Processing Thickness |

0.3-0.8 mm |

|

3 |

Material of Roller |

45#steel |

|

4 |

Material of Shafts |

45#steel |

|

5 |

Total Power |

8kw |

|

6 |

Material of Cutting Blades |

Cr12 |

|

7 |

Brand of PLC |

Delta/Mitsubishi/Siemens |

|

8 |

Production Speed |

10-15 m/min |

|

9 |

Brand of Frequency Converter |

Delta/Mitsubishi/or as clients requirements |

|

10 |

Transmission Type |

Chain transmission+Decelerating motor |

|

11 |

Voltage |

380 V 50 HZ or as clients requirement |

|

12 |

Cutting Type |

Mold Cutting |

Machine details

The Spare Parts of the Galvanized Steel Sheet Cold Roller Forming Machine

1. Galvanized Steel Sheet Cold Roller Forming Machine Manual Decoiler and hydraulic fully automatic style part

Usage:It is used to support the steel coil and uncoil it in a turnable way.Passive uncoil pulled by roll forming system

2.Galvanized Steel Sheet Cold Roller Forming Machine Coil feeding part

Usage:Put the raw material(steel plate) through the beach to manufacture and process,it can guarantee that the products are neat, parallel and everything is uniformity.

Please refer to the equipment regulation to know the function of locate angle iron.

Used Metal Roof Panel Roll Forming Machine

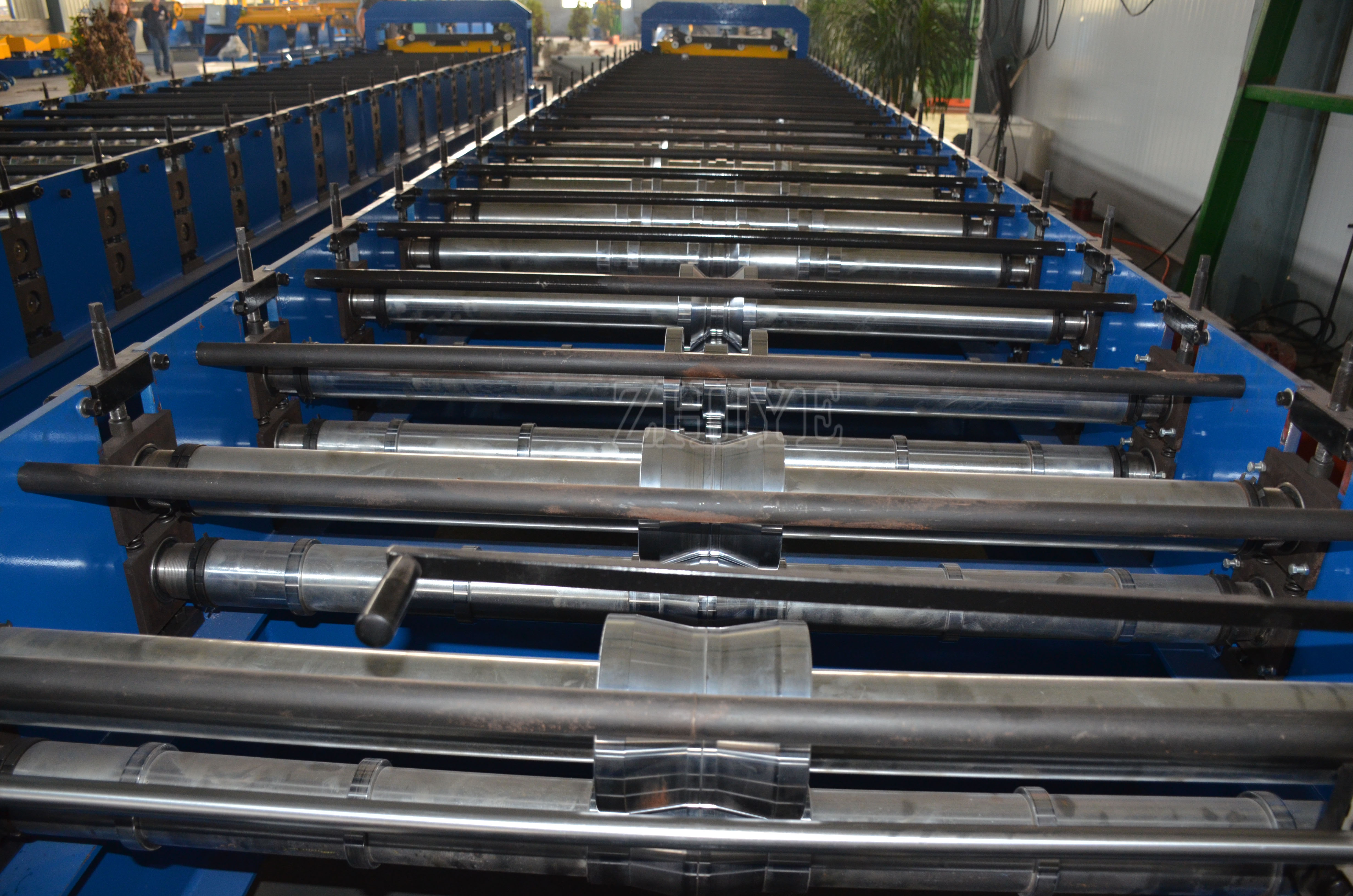

3.Galvanized Steel Sheet Cold Roller Forming Machine Main roll forming machine part

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working

4.Galvanized Steel Sheet Cold Roller Forming Machine Automatic Cutting System

Components:It contains one set of blade, one hydraulic tank and one cutter machine

5. Galvanized Steel Sheet Cold Roller Forming Machine Computer controlling parts

1).PLC brand: Normally, it is Delta. Mistubishi, Panasonic, Siemens are optional.2).working model: fully automatic and manaul.3).working language: normally are English, Chinese,Russia. Can be set as per your requirements.

6.Galvanized Steel Sheet Cold Roller Forming Machine Hydraulic station

1).including one motor,one oil tank,one magnetic valve,one pressure gage, hydraulic oil tube.2).3kw,4kw,5.5kw,will be adopted as per your profile sheet.

Galvanized Steel Sheet Cold Roller Forming Machine Packaging & Shipping

Contact us if you have any questions about Galvanized Steel Sheet Cold Roller Forming Machine.

Cangzhou, Hebei, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Organization

- Service

- Trade Company

- OEM service

- Platform Certification

- Video

Send your inquiry to this supplier