1 / 5

Galvanized steel roller shutter door lath forming machinery

| Model No. : | customized |

|---|---|

| Brand Name : | dixin |

| Certification : | ISO |

Product description

Galvanized steel roller shutter door lath roll former machinery

The roller shutter door lath roll former machinery of Galvanized steel roller shutter door adopts a unique process to make the door body's main frame profile, which is connected by plastic parts. The screw fixing of the connection position adopts concealed design to improve the appearance of the door body. The connection between the profile and plastic parts adopts the processes of punching, pressing and drilling, so that the door body structure is firm without solder spots.Cross connection design: the cross pipe is made by special process and equipped with super PA wear-resisting sleeve. The close combination with the round pipe not only makes the door row structure more firm, but also ensures smooth operation.

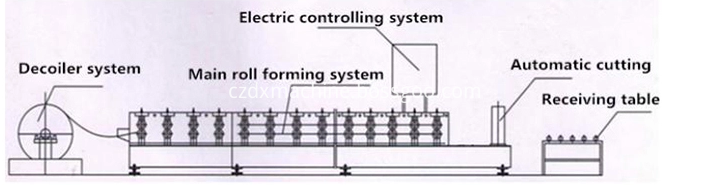

Working flow

These drawing may have what you need

Technical Parameter

|

No. |

main parameter of Shutter Door Roll Forming Machine

|

|

|

1 |

Suitable to process |

Galvanized Steel |

|

2 |

Width of the plate |

100mm |

|

3 |

Rollers |

12 stations |

|

4 |

Dimensions |

4M*0.8M*1.2M |

|

5 |

Power |

3KW |

|

6 |

Thickness of the plate |

0.3-0.8mm |

|

7 |

Productivity |

8-10m/min |

|

8 |

Diameter of the roller |

Φ50mm |

|

9 |

Weight |

About 3T |

|

10 |

Voltage |

380V 50Hz 3phases |

|

11 |

Material of the cutting plate |

Cr12 |

|

12 |

Hydraulic |

40# oil |

|

13 |

Processing precision |

Within 1.00mm |

|

14 |

Control system |

PLC control |

|

|

Use

The best quality machine materials and accessories

Packaging

About our company

Our service

1.We have professional team to make different kinds of roll forming machines for our customers,

from designing, processing,assembling, debugging, delivery.

2.we can send our engineer to your site and do the training for your worker. you just only bear the cost for our engineer's air ticket,visa,accommodation,food and transpotaion in your country.

3.You can send your worker to our factory. we will teach them how to operate the machine without training charges.

We can produce too many types roofing panels roll forming machine ,especially according to your request to produce.

you need provide panel drawing,feeding width,effective width,and materials thickness,

then we can send you more machine details.

Please feel free contact me.

Send your inquiry to this supplier