1 / 1

Full Automatic Salt Packaging Machinery

| Model No. : | GQ-520 |

|---|---|

| Types of : | Multi-Function Packaging Machine |

Jinan, Shandong, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Platform Certification

Product description

Full Automatic Salt Packaging Machinery

Full Automatic Pet Food Packaging Machinery

Full Automatic Melon Seeds Packaging Machinery

Full Automatic Rice Packaging Machinery

I. 520 complete set Include five parts:

① GQ-520 automatic vertical packaging machine

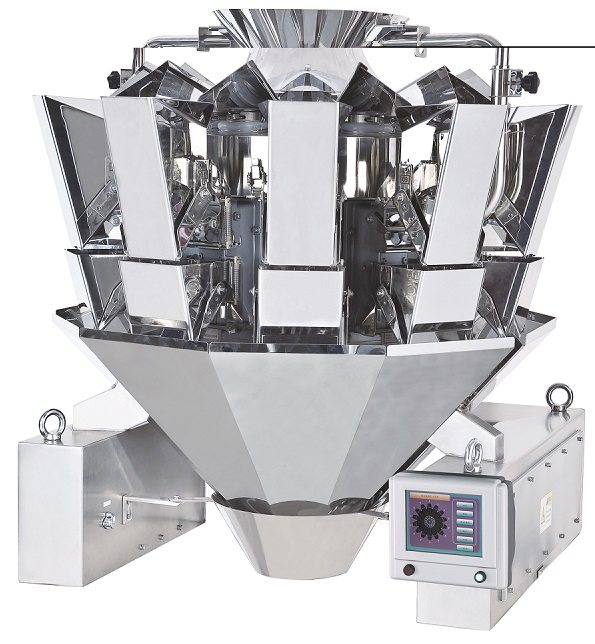

② 10-head computer combination scale

③ Z-type material conveyor (with vibration device)

④ Finished product conveyor

⑤ Working platform

Application:

Suitable for the packaging of bulk objects requiring high metering accuracy and fragility, such as puffed food, potato chips, potpourri, jelly, candy, pistachios, peanuts, beans, apple slices, dumplings, dumplings, herbs, etc.

III, Introduction of the machine.

1. GQ-520 automatic vertical packaging machine

* Imported PLC full computer control system, full Chinese/English touch screen operating system, clearly display the working status and operation instructions.

* High precision servo film transport system, smooth film transport, with the photoelectric automatic positioning tracking system, high positioning accuracy.

* Intelligent digital temperature control system, stable temperature difference control, with a tooth-shaped sealer to ensure firm sealing.

* Including automatic fault alarm display function, such as low temperature, no packaging film, no ribbon, no material, servo fault, no color code signal, and automatic alarm or stop function when the glass protection door is opened.

* The machine can automatically complete the whole packaging process of metering, feeding, bag filling, date printing, and finished product output with the matching of the metering device.

Technical parameters:

| Model | GQ-520 |

| Packing speed | 10-60 bag/min |

| Bag size | (L)50-300mm (W)60-250mm |

| Film thickness | 0.06-0.10mm |

| Air consumption | 0.4m3/min 0.6MPa |

| Bag material | Heat sealable laminates film(OPP/CPP、OPP/CE、MST/PE、PET/PE) |

| Total power/voltage | 3KW/220V 50-60Hz |

| Overall dimension | 1430×1200×1700mm |

| Gross weight | 650kg |

2. 10-head computer combination scale

(1)Applicable products:

Candy, melon seeds, potato chips, pistachios, peanuts, jelly, frozen dumplings, cookies, chocolate, nuts, pet food, puffed food, small hardware, plastic parts and other kinds of granular, flaky, strip, irregular-shaped materials quantitative weighing.

(2) Main performance and structural features:

* Perfect combination of high precision and high speed, the best combination is instantly selected from the rich weight combination by computer calculation.

* High precision digital load cell makes accurate measurement instantly possible.

* IP65 rated water and dust proof design. All parts are made of stainless steel for clean and hygienic use. Fully sealed design prevents material build-up and is easy to clean.

* Fine adjustment of the hopper door opening and closing speed according to the characteristics of the material to be measured, preventing crushing and jamming.

* Powerful automatic data statistics function, recording the total number of bags produced in each batch, qualification rate and single bag error and other indicators.

* Selection structure device: patterned weighing hopper, collecting hopper, printing device, super differential selection device.

* Multi-language LCD operating system such as Chinese/English. Strong compatibility, directly mounted on top of the packaging machine, more compact structure.

* Save a lot of raw material and labor cost for you, quick return on investment.

* Parameters:

Net weight: 300Kg;

Gross weight: 370Kg

Voltage: 220V;

Power: 1500W;

Frequency: 50/60HZ;

Rated current: 9A

(2) Technical parameters:

| Model |

Ten-head computer combination scale |

|

Single weighing range |

10-1000g |

|

Max. weight |

3000g |

|

Weighing accuracy range |

0.1-1.5g |

|

Max. weighing speed |

70bag/min |

|

Hopper capacity |

1300ml |

|

Hopper type |

Double row without memory bucket |

|

Drive mode |

Stepper motors |

|

product preset number |

99 |

|

Overall dimension(mm) |

1150(L)X950(W)X1129(H) |

3. Z-type material conveyor (with vibration device)

1)Introduction

This elevator is suitable for vertical lifting of granular materials in the departments of grain, food, feed and chemical industry. The elevator is driven by the chain drive to lift the hopper, used for vertical conveying of granular and small lumpy materials, with the advantages of large lifting capacity and high lifting degree.

2)Technical parameters

Lifting height :can be determined by customer

Total power :500w

Lifting speed :0-17m/min

Lifting capacity:5.5m3/hour

4. Finished product conveyor

(Function: Convey the automatically packed finished bags to the post-packaging inspection equipment or packing platform)

Size:2110×340×500mm

Voltage: 220V/45W

Conveying speed :30m/min

4. Working platform

Jinan, Shandong, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Platform Certification

Send your inquiry to this supplier