Video

1 / 3

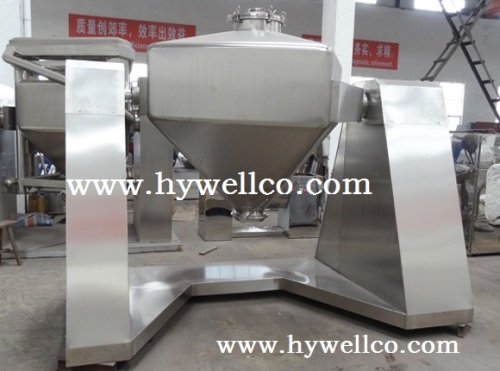

fixed bin blender for powder

$5000.00

≥1 Set/Sets

| Brand Name : | HYWELL |

|---|---|

| Mixing type : | Agitator |

Changzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Hywell machinery's fixed bin blender is designed for ultra-uniform mixing of a wide range of powder and granular products in the pharmaceutical, chemical, food, light and related industries. This type of powder mixer has a three dimensional mixing method for high efficiency mixing unlike other 2D mixers.

The fixed bin blender features novel design, compact structure, and good appearance; The evenness of mixing reaches 99%, and the volume charge coefficient reaches 80%, compared to 40%-50% of other blenders.

Hywell machinery’s cone blender have the lab model, and the cone mixer machine have the volume drum of 5-50L that can work with interchangeable drums.

Fixed Bin Blender Introduction

Hywell Machineryfixed bin powder blender are used for homogeneous mixing of powdery substances with different specific weights and particle sizes. The production process is hygienic and dust-free because the product is mixed in independent containers of variable sizes. During the mixing process the powder moves on a random direction from center to the end of the trough and on the same time from top to the bottom. In such a multi-dimensional way.

Materials are charged into a closed square-cone mixing barrel, the symmetrical axes of hopper and the axes of rotating shaft form an included angle, materials with different constituents are strenuously rolling over in the closed hopper and producing high shear to achieve the best effect of mixing. For the materials, there is no centrifugal function, without the specific gravity segregation and the layer division. For each of build-up phenomenon, there is the remarkable weight rate. The mixing rate is high. The material charge rate of barrel is big. Maximum rate can be up to 80% . The barrel adopts arc shape connections and its well polished and reach GMP.

Square cone mixer Working Principles

During the mixing process the powder moves on a random direction from center to the end of the trough and on the same time from top to the bottom. the HF series powder mixing machine needs only short mixing time and relatively low power consumption. The mixer‘s “Gentle” mixing action is good for final products that are sensitive to high shear of the mixer and tend to break or to reduce their particles size, or are highly abrasive.

The fixed bin mixer is composed of machine base, driving system, control system, mixing bin and so on. When it works, after materials are fed into the bin, lock the feeding cover. Set the blending time and blending speed according to your process requirements. Start the control system, and start the blending operation. When the set time is reached, the equipment will stop automatically. The printer can print the records according to the set items and process parameters.

The Fixed Bin Powder Blenders the whole process adopts PLC and interface automatic control system, guarantee homogenous blending. The process parameters can be recorded and printed for each batch. you can analyze and monitor the blending processes of the bin blenders. The highly sensitive infrared sensor device to ensure safety and prevent wrong operation. Inside of pharma bin smooth without dead corners and mix in a sealed space to avoid dust and cross contamination, realizes dust free production.

Fixed Bin Blenders are widely used in pharmaceutical industry mainly for mixing of granules and powder. Meanwhile, it can be widely used in such as raw material industry, chemical industry, foodstuff industry, etc. It has advantage of stable transmission, reliable structure, large mixing amount, homogenous blending for dry granules and powder.

If you are looking for HF Series Fixed Cone Blender and have detailed requirement ideas in mind, You tell us what you want, and we will custom your best Bin Blenders.

fixed bin powder mixer specifications

|

Model |

Total volume (L) |

Operation Volume(L) |

Maximum loading (Kg) |

Speed of mixing (r/min) |

Power (kw) |

Size (mm) |

Weight (Kg) |

|

HF-10 |

5 |

4 |

2 |

10-25 |

0.55 |

1000x900x800 |

120 |

|

HF-20 |

20 |

16 |

8 |

10-20 |

0.75 |

1000x900x800 |

180 |

|

HF -50 |

50 |

40 |

20 |

8-15 |

1.1 |

1200x1100x1000 |

300 |

|

HF-100 |

100 |

80 |

40 |

8-15 |

1.1 |

1300x1200x1800 |

500 |

|

HF-200 |

200 |

160 |

80 |

8-15 |

1.5 |

1600x1280x1900 |

800 |

|

HF-400 |

400 |

320 |

160 |

8-15 |

2.2 |

1700x1280x1950 |

1200 |

|

HF-600 |

600 |

480 |

240 |

8-15 |

2.2 |

2200x1600x2200 |

1500 |

|

HF-800 |

800 |

640 |

320 |

8-15 |

4 |

2800x1900x2820 |

2000 |

|

HF-1000 |

1000 |

800 |

400 |

5-10 |

4 |

2800x2000x2820 |

2500 |

|

HF-2000 |

2000 |

1600 |

800 |

5-10 |

7.5 |

3300x2550x3280 |

2800 |

|

HF-3000 |

3000 |

2400 |

1200 |

5-10 |

11 |

3800x3000x3800 |

3500 |

|

1.5-50L can work with interchangeable drums. 2.Bigger size up to 5000L are available against request 3.Hywell machinery reserves the right to .the design without notice 4.All specifications are as accurate as is reasonably possible, but they are not binding. |

|||||||

Square cone blender construction material

Hywell Machinery are able to offer our HF Series Square cone blender with contact part to be built in SS304, SS316L, Titanium, Duplex stainless steel, etc. Electrical parts of control system of the Powder mixing machine can be adapted to the customer’s needs.

Cone Mixing Machine Advantages

Hywell machinery HF series Mixing Machine had the following advantages over conventional solutions.

1. Excellent homogeneity of mixing with no dead points

2. Complete discharge and easy cleaning

3. Easy loading of materials into the shells.

4. Blender automatically stops at the home position after blending is complete.

5. Safety cage to prevent human injury

6. Mixing in independent containers (on small models as an Option) offers no contamination and emissions, no extra cleaning.

7. Time-saving, fast exchange of the container, due to simple and fast mounting of the container

8. The whole machine novel design, compact structure, and good appearance, the evenness of mixing reaches 99% , and the volume charge factor reaches 0.8.

9. Highly polished inner and outer surfaces of the barrel, no dead comer, easy to discharge materials, easy to clear, no cross contamination. Confining to the requirement of GMP.

10.With large production capacity, convenient maintenance and cleaning

11. Fixed Bin Blender adopts PLC and HMI automatic control system

12. Reasonable structure, stable performance and simple operation

Video

Changzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier