1 / 5

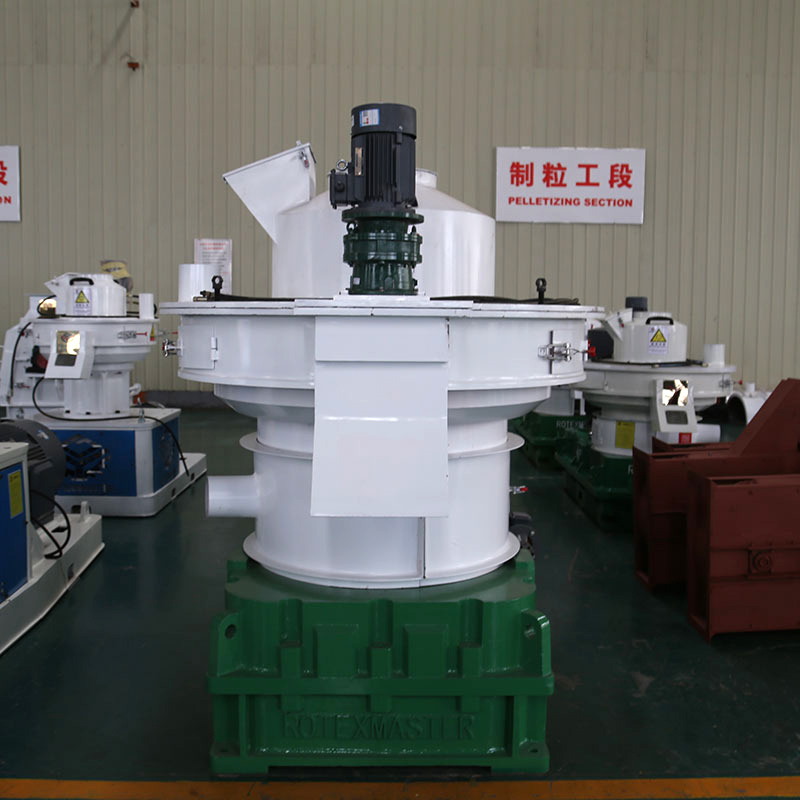

Efficient Vertical Ring Die Pellet Machine

| Model No. : | YGKJ560 |

|---|---|

| Brand Name : | Rotexmaster |

| Certification : | CE.ISO |

Product description

Is a professiona equipment to produce biomass fuel pellets & poultry feed pellets,pellet size 4-12mm. All kinds of biomass raw materials could be compressed into biomass pellets,such as wood logs,sawdust,wood chips,rice husk,cotton seeds,olive waste,efb fiber,cotton straw etc. Wood pellet complete production line includes

Wood chipper (crushing wood logs into chips) -- hammer mill (grinding different biomass powder) -- rotary dryer (drying 5-100mm biomass particles or powder) -- biomass wood pellet machine (making biomass pellets) -- counter flow cooler (cooling biomass pellets) -- packing machine (packing pellets into bags automatically)

Main Features of Vertical Ring Die Wood Pellet Machine

1) The motor and main shaft are parallel vertical installed , which can reduce energy consumption loss in the process of transmission, more output power, higher transformation of energy efficiency.

2) The gearbox adopts independent research and development big gear with 3 level drive , module increased , gear strengths increased , carrying more power and more stability ,in addition ,Good meshing, smooth transmission, small vibration and low noise, the service life increased 8-10 times than the traditional reducer , greatly increase the service life

3) Gear box body is casted ,Its advantages has strong,good heat dissipation,low heat deformation,high steady etc .Avoid disadvantages of the bad sealing for welding body,easily deformation due to high heat,low steady in basis etc.

4) Bearing room structure is smaller,make the whole structure compact,It guarantee th bearing room,pelleting room working steady.The hollow shaft connect directly with spline shaft in bearing room,guarantee high concentricity,reduce the failure rate of equipment.

5) Roller use the independent new design unlocked enclosed roller, roller sealing better,

reduce fuel consumption, extended lifetime of roller bearings, reduce cost and increase efficiency.

Send your inquiry to this supplier