1 / 6

eddy current testing and ultrasonic flaw detector testing system for metal tubes and bars

| Model No. : | IDEA-EUT02 metal detectors system |

|---|---|

| Brand Name : | IDEA metal detectors system |

Product description

ET and UT testing system/NDT testing equipment 1.Independent R&D

ET and UT testing system/NDT testing equipment 1.Independent R&D 2.Factory production,quality assurance

3.Stable performance high precision

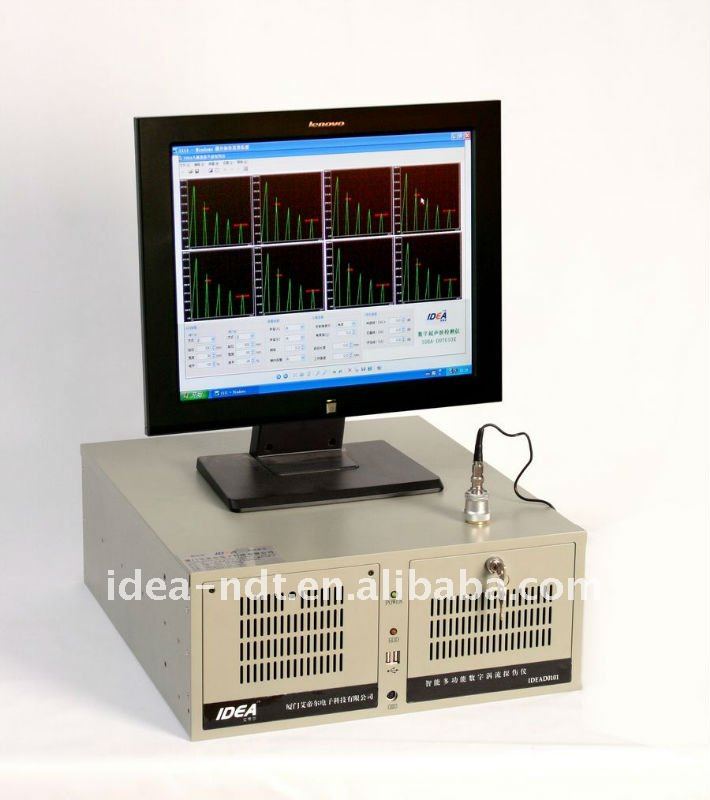

4High-quality after-sale service 1. UT machine/NDT testing equipment sketch NDT Digital Ultrasonic flaw detector Fully digital smart multichannel ultrasonic flaw-testing machine combining the internationally-advanced digital integration technology and ultrasonic technology is practical, stable in performance, easy to operate and affordable.

NDT Digital Ultrasonic flaw detector is extensively used for automatic (or semiautomatic) ultrasonic nondestructive testing to tubular products like titanium tubes, zirconium tubes, seamless steel tubes, welded natural gas/oil delivery pipes, nonferrous and ferrous tubes, rods or plates or a part of nonmetal tubes, rods and plates, as well as railroad rails. 2. NDT Digital Ultrasonic flaw detector/testing machine Parameters:

1) Gain 0-110dB, step 0.1dB

2) Detection channels 1\2\4\8\16, 32

3) Operation mode Single probe transmitter and receiver, dual probe transmitter and receiver

4) Scan mode A\B\C type scan

5) Surplus Sensitivity ≥ 65dB

6) Resolution ≥ 36dB

7)Dynamic range ≥ 42dB

8)Scan range(steel longitudinal wave) 0~6000mm

9)Frequency range 0.5~20MHz

10)Repetition frequency 100Hz~10KHz adjustable

11)Vertical linearity ≤ 3%

12)Horizontal linearity ≤ 1%

13)Gate setting Each channel has three gates, alarm gate, tracking gate, self locking gate

14)Delayed (marking) alarm split in two, delayed time: 0.5~10S, step: 0.1S

Testing conditions and flaw wave form Quantity unrestricted, invocation, wave replay\wave communicate\wave print

15)Test report Automatic generate(WORD \EXECL)

16)Parameter storage Detection state parameters\echo pattern\DAC curve and remark information etc.

17)Clock Type Inner, outer CLOCK

18)Encoder 50-1024 (Optional)

19)Detector mode positive, negative, bi-directional, radio frequency (RF)

20)Peak memory Can choose echo peak memory display, background peak wave can be in a different color represents.

21)SA\PA\RA\% Real-time display

eddy current testing equipment/surface crack detector parameters

eddy current testing equipment/surface crack detector parameters Parameter |

1. Testing channel: 1 2 4 8 16 32 2. Frequency range: 10 Hz~10 MHz,to meet various metal material testing requirements. 3. Gain: 0 dB ~ 110 dB, continuously adjustable, the work of each file 0.1dB step 4. Phase: 0 ~ 359 °, continuously adjustable, continuously adjustable, precision 1 ° 5. Gain ratio: (X/Y)0.1~10.0 6. Testing speed: <=120m/min 7. Adjustable probe drive rank: 1~16 8. Fast digital / analog electronic balance 9. Non-amplitude, unsymmetrical phase alarm region setting 10. Various display: impedance, time base display 11. Digital Filtering: High-pass frequency (0Hz ~ 2000Hz), low-pass frequency (0Hz ~ 2000Hz) 12.Filtering points: 0—1024 13.Pre-amplication: 1-32dB 14. Delayed hardware output alarm, real-time hardware output alarm 15.Delayed,fixed length mark,precision0—65536ms/0—9999.999MM 16.Auto balance time: -1~1024 17.Multi-mode inside and outer clock, encoder I/O input and output unit. 18.Resection function for end socket and tail end signal 19. Mass storage of various test procedures and test data 20. Eddy current testing signals playback, and the defects amplitude, phase and digital value measurement 21. Automatically record and display the number and the position of defects. 22. Display modes: solid line and blanking display 23. Blanking display coefficient: 1~200 24. English and Chinese operating languages, on-line help 25. Rectangular coordinate system and polar coordinates background for choices 26. Automatically display the date and time 13. Sound-light alarm output 14. Charging power supply: 110V/60HZ 220V/50HZ Power Dissipation<=300W

|

Application | Applied to the ndt (non-destructive) detecting of metal material. For example, weldless steel tubes, petroleum pipes, metal welded tubes, non-ferrous metal tubes, stainlesssteel tubes, metal plates, alloy steel, carbon steel and other metal material. |

Xiamen IDEA Electronic Technology Co., Ltd MS.Emily Liu Tel: +86-0592-6301909 Fax: +86-0592-6301919 Mobile: +86-13599504218 skype: liu.emily52 Web:http://www.idea-ndt.com Address: Floor 2, NO.20,Tong'an industrial park, Huangdong Waters, Tong'an, Xiamen ,China 361100

Xiamen IDEA Electronic Technology Co., Ltd MS.Emily Liu Tel: +86-0592-6301909 Fax: +86-0592-6301919 Mobile: +86-13599504218 skype: liu.emily52 Web:http://www.idea-ndt.com Address: Floor 2, NO.20,Tong'an industrial park, Huangdong Waters, Tong'an, Xiamen ,China 361100 Send your inquiry to this supplier