1 / 6

DX-12.0III-DX Large vacuum timber drying chamber with dielectric generator

Get Latest Price

Send Inquiry

| Model No. : | DX-12.0III-DX |

|---|---|

| Brand Name : | DAXIN |

Shijiazhuang Development Zone Daxin Electronic Technology Co., Ltd.

You might also like

Product description

DX-12.0III-DX Large vacuum timber drying chamber with dielectric generator

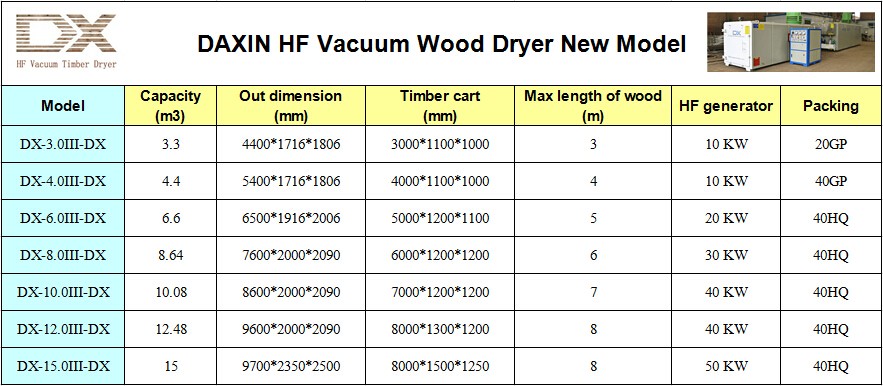

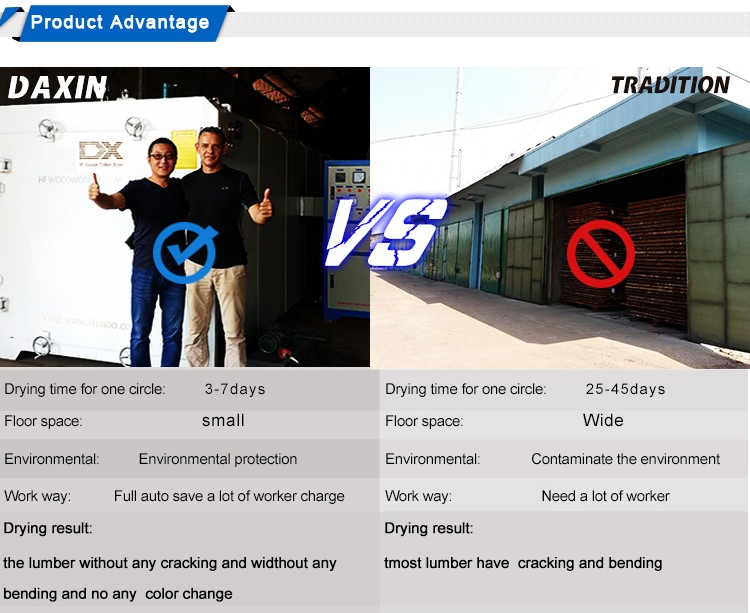

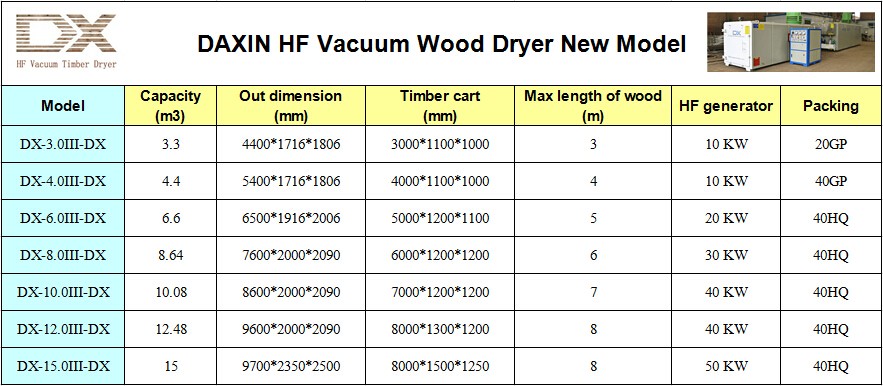

Product Description Daxin Electronic Science And Technology Co., Ltd. is one of the leading manufacture factory of high frequency vacuum wood drying equipment and high frequency generator in Hebei Province,China. In this industry more than 20 years, we have the Natioanl patent certification and CE certification, SGS certification. It is the newest drying technology in woodworking machinery industry. We can supply capacity 3cbm, 4cbm, 5cbm, 6cbm, 8cbm, 10cbm, 12cbm. It sold in Japan, Thailand, Vietnam, USA, UK, Canada, Uganda, New Zealand, Bulgaria, Iran, Indonesia, Tanzania, Austria etc. Now very popular drying technology in China. Three main parts of HF vacuum wood dryer machine: High strength steel structural vacuum square oven High frequency generator Cooling tower

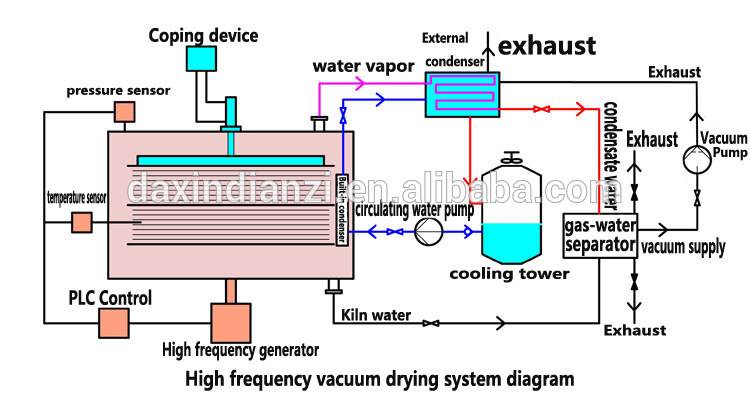

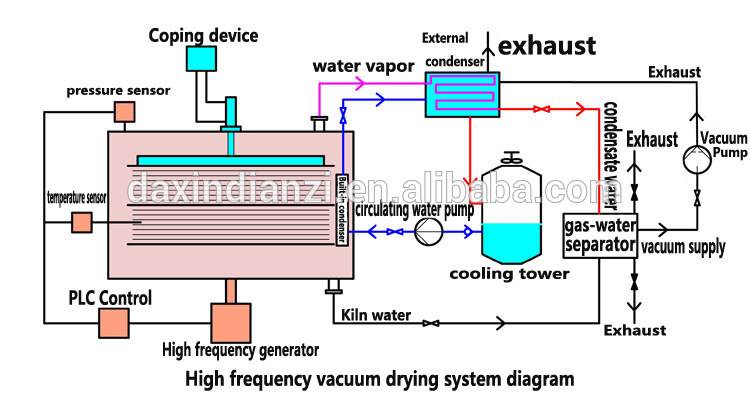

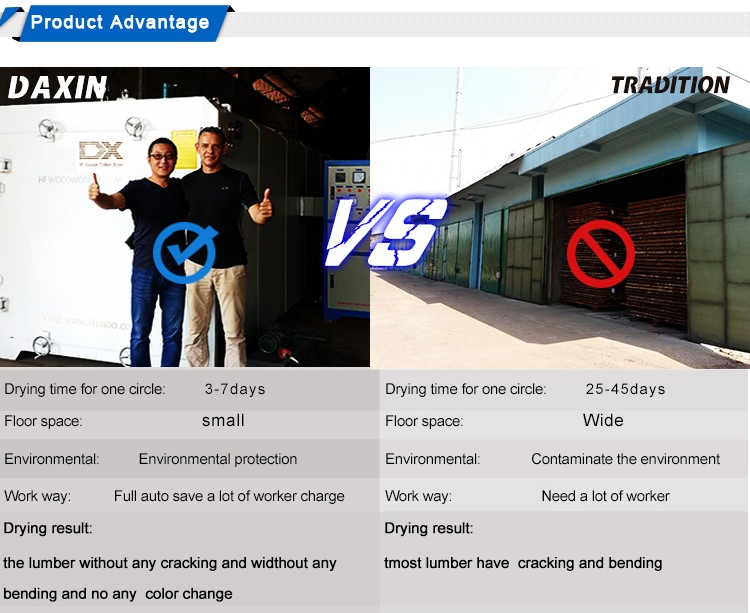

Three main parts of HF vacuum wood dryer machine: High strength steel structural vacuum square oven High frequency generator Cooling tower  HF vacuum wood drying equipment adopts high frequency drying, inside and outside of wood timber is heated at same time, uniform heating, high speed drying, short time and good quality, which can keep the timber nature color, meanwhile, the timber is aerated under the vacuum environment, non-cracking, especially applied for the thick and hard precious wood, wet wood. Drying eucalyptus timbers from wet of saw to a final mositure content of about 8-12%. HF generator is the core of dielectric heating equipment. It applies three phase alternating current to form frequency oscillation electric field .Under this high frequency electric field, the molecules like water .glue or PVC will be polarized and form two poles. The electric field will change pole rapidly meanwhile all the molecules will also move in very high speed. The friction and impact among molecules can make material get heated in short time. Then the water will be vaporized, glue becomes solid and PVC gets softened rapidly.

HF vacuum wood drying equipment adopts high frequency drying, inside and outside of wood timber is heated at same time, uniform heating, high speed drying, short time and good quality, which can keep the timber nature color, meanwhile, the timber is aerated under the vacuum environment, non-cracking, especially applied for the thick and hard precious wood, wet wood. Drying eucalyptus timbers from wet of saw to a final mositure content of about 8-12%. HF generator is the core of dielectric heating equipment. It applies three phase alternating current to form frequency oscillation electric field .Under this high frequency electric field, the molecules like water .glue or PVC will be polarized and form two poles. The electric field will change pole rapidly meanwhile all the molecules will also move in very high speed. The friction and impact among molecules can make material get heated in short time. Then the water will be vaporized, glue becomes solid and PVC gets softened rapidly.  Details Images A. Mahogany drying from 40%-50% to 5%-10% take about 3-4days :

Details Images A. Mahogany drying from 40%-50% to 5%-10% take about 3-4days :

B. Walnut drying from 40% to 10% take about 4-5days :

B. Walnut drying from 40% to 10% take about 4-5days :  C. Rosewood drying from 50% to 10% take about 4-5days:

C. Rosewood drying from 50% to 10% take about 4-5days:  D. Teak wood drying from 40% to 8% take about 3-4days:

D. Teak wood drying from 40% to 8% take about 3-4days:

Packaging & Shipping

Packaging & Shipping  Why choose us? Professional worker team at factory. Professional sale team at office. Professional engineer team at customer's factory. Professional wood dryer machine;s technology. Professional after-sales service for customer.

Why choose us? Professional worker team at factory. Professional sale team at office. Professional engineer team at customer's factory. Professional wood dryer machine;s technology. Professional after-sales service for customer.  Guarantee and After-sell Service Warranty: 1 year for the whole machine. (If there were some parts broken by itself, we can supply the parts freely within 1 year.) After-sale service: Our Professional engineers can provide overseas installation, training and Perfect after-sales service and maintenance. ---24 hours technical support by e-mail ---Calling or door-to-door service ---User manual and detailed video Thank you for visiting our website, pls contact with us freely!

Guarantee and After-sell Service Warranty: 1 year for the whole machine. (If there were some parts broken by itself, we can supply the parts freely within 1 year.) After-sale service: Our Professional engineers can provide overseas installation, training and Perfect after-sales service and maintenance. ---24 hours technical support by e-mail ---Calling or door-to-door service ---User manual and detailed video Thank you for visiting our website, pls contact with us freely!

Product Description Daxin Electronic Science And Technology Co., Ltd. is one of the leading manufacture factory of high frequency vacuum wood drying equipment and high frequency generator in Hebei Province,China. In this industry more than 20 years, we have the Natioanl patent certification and CE certification, SGS certification. It is the newest drying technology in woodworking machinery industry. We can supply capacity 3cbm, 4cbm, 5cbm, 6cbm, 8cbm, 10cbm, 12cbm. It sold in Japan, Thailand, Vietnam, USA, UK, Canada, Uganda, New Zealand, Bulgaria, Iran, Indonesia, Tanzania, Austria etc. Now very popular drying technology in China.

Three main parts of HF vacuum wood dryer machine: High strength steel structural vacuum square oven High frequency generator Cooling tower

Three main parts of HF vacuum wood dryer machine: High strength steel structural vacuum square oven High frequency generator Cooling tower  HF vacuum wood drying equipment adopts high frequency drying, inside and outside of wood timber is heated at same time, uniform heating, high speed drying, short time and good quality, which can keep the timber nature color, meanwhile, the timber is aerated under the vacuum environment, non-cracking, especially applied for the thick and hard precious wood, wet wood. Drying eucalyptus timbers from wet of saw to a final mositure content of about 8-12%. HF generator is the core of dielectric heating equipment. It applies three phase alternating current to form frequency oscillation electric field .Under this high frequency electric field, the molecules like water .glue or PVC will be polarized and form two poles. The electric field will change pole rapidly meanwhile all the molecules will also move in very high speed. The friction and impact among molecules can make material get heated in short time. Then the water will be vaporized, glue becomes solid and PVC gets softened rapidly.

HF vacuum wood drying equipment adopts high frequency drying, inside and outside of wood timber is heated at same time, uniform heating, high speed drying, short time and good quality, which can keep the timber nature color, meanwhile, the timber is aerated under the vacuum environment, non-cracking, especially applied for the thick and hard precious wood, wet wood. Drying eucalyptus timbers from wet of saw to a final mositure content of about 8-12%. HF generator is the core of dielectric heating equipment. It applies three phase alternating current to form frequency oscillation electric field .Under this high frequency electric field, the molecules like water .glue or PVC will be polarized and form two poles. The electric field will change pole rapidly meanwhile all the molecules will also move in very high speed. The friction and impact among molecules can make material get heated in short time. Then the water will be vaporized, glue becomes solid and PVC gets softened rapidly.  Details Images A. Mahogany drying from 40%-50% to 5%-10% take about 3-4days :

Details Images A. Mahogany drying from 40%-50% to 5%-10% take about 3-4days :

B. Walnut drying from 40% to 10% take about 4-5days :

B. Walnut drying from 40% to 10% take about 4-5days :  C. Rosewood drying from 50% to 10% take about 4-5days:

C. Rosewood drying from 50% to 10% take about 4-5days:  D. Teak wood drying from 40% to 8% take about 3-4days:

D. Teak wood drying from 40% to 8% take about 3-4days:

Packaging & Shipping

Packaging & Shipping  Why choose us? Professional worker team at factory. Professional sale team at office. Professional engineer team at customer's factory. Professional wood dryer machine;s technology. Professional after-sales service for customer.

Why choose us? Professional worker team at factory. Professional sale team at office. Professional engineer team at customer's factory. Professional wood dryer machine;s technology. Professional after-sales service for customer.  Guarantee and After-sell Service Warranty: 1 year for the whole machine. (If there were some parts broken by itself, we can supply the parts freely within 1 year.) After-sale service: Our Professional engineers can provide overseas installation, training and Perfect after-sales service and maintenance. ---24 hours technical support by e-mail ---Calling or door-to-door service ---User manual and detailed video Thank you for visiting our website, pls contact with us freely!

Guarantee and After-sell Service Warranty: 1 year for the whole machine. (If there were some parts broken by itself, we can supply the parts freely within 1 year.) After-sale service: Our Professional engineers can provide overseas installation, training and Perfect after-sales service and maintenance. ---24 hours technical support by e-mail ---Calling or door-to-door service ---User manual and detailed video Thank you for visiting our website, pls contact with us freely!

Send your inquiry to this supplier

Send Inquiry