1 / 3

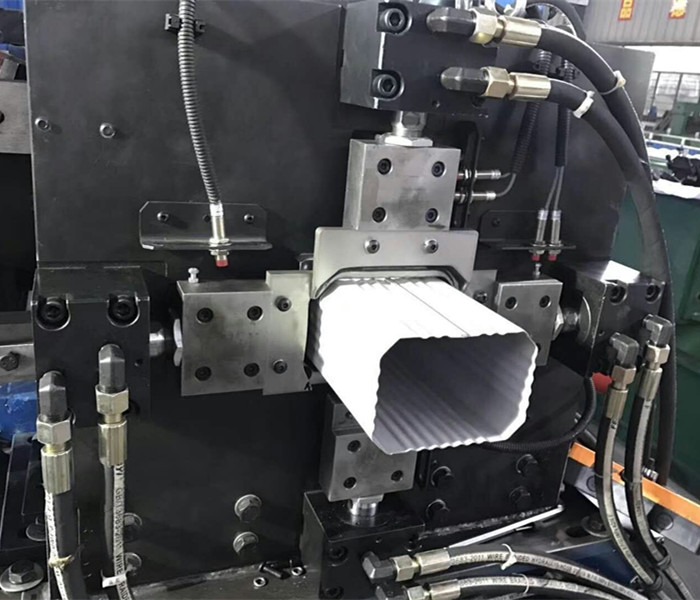

Downpipe gutter pipe rolling forming machine

| Certification : | CE |

|---|

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

The final product can be cut as per set length controller,and the length is automatically measured by encoder.When final product reached set length,machine will stop to cut the sheet automatically.Finish thhis action,the machine will run again continuously.It is composed of decoiler ,roll forming part,hydraulic mold cutting,elbow bending machine.

If you want to make a complete rain water down pipe system,downpipe machine and elbow bending machine are required.

Steel gutter downpipe rolling forming machine is designed for production of round downspout.It is composed of manual decoiler,main forming,automatic cutting,elbow bending.it is formed from cooper,color coated aluminum,pre painted galvanized steel.

Manual uncoiler

|

No. |

Manual decoiler parameters |

|

|

1 |

Loading Capacity |

3 T |

|

2 |

Expanding inner diameter |

450-550mm

|

|

3 |

Feeding width |

Max 500mm |

picture of Main roll forming machine

|

No. |

Main parameter of steel pipe roll forming machine |

|

|

1 |

Suitable to process |

Color steel plate |

|

2 |

Width of the plate |

As customer need |

|

3 |

Thickness of the plate |

0.5-0.8mm |

|

4 |

De-coiler |

Manual one, can load 3 tons raw material |

|

5 |

Rollers for forming |

19 rows |

|

6 |

Diameter of the roller |

Φ60mm |

|

7 |

Rolling material |

Carbon Steel no. 45 |

|

8 |

Main motor power |

5.5kw |

|

9 |

Productivity |

8-10m/min |

|

10 |

Cutting method |

mold cutting |

|

11 |

Material of the cutting blade |

Cr12 |

|

12 |

Hydraulic cutting power |

3kw |

|

13 |

Processing precision |

Within 2.00mm |

|

14 |

Control system |

Panasonic PLC control |

|

15 |

Main structure of the machine |

300 H steel |

|

16 |

Weight |

About 7.5T |

|

17 |

Dimensions |

17*1.2*1.4m |

|

18 |

Voltage |

380V 50Hz 3phases(changeable as needs) |

Terms of payment:

30%T/T ,70% Balance to be paid before shipping after inspection

Warranty

1. One year warranty, whole life technical support.

2. Installation & adjustment: We can take video for the customer

and customer can also come to our factory, we can train customer

how to install and adjust the machine.

3. Oversea service: the buyer should charge of visa, return ticket,

food and accommodation overseas and USD50/person/day salary.

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier