1 / 2

Design of electroplating materials

Shenzhen, Guangdong, China

- Manufacturer

- OEM service

- Platform Certification

- The Belt And Road

Product description

1. The basic principle of electroplating design

Electroplating parts in the design of a lot of special design requirements can be raised, roughly the following:

1. The substrate is best to use ABS material, ABS plating after the adhesion of the film is better, while the price is relatively low.

2. Plastic surface quality must be very good, electroplating can not cover some of the defects of injection, and usually make these defects more obvious.

3. In the structural design of a few points have to pay attention to shape to be suitable for plating treatment:

1) The surface protrusion is best controlled at 0.1 ~ 0.15mm / cm, as far as possible without sharp edges.

2) If there is a blind hole design, the depth of the blind hole is best not more than half of the aperture, responsible for not the bottom of the hole color requirements.

3) to use the appropriate wall thickness to prevent deformation, preferably in the 1.5mm above 4mm, if you need to make a very thin, then in the corresponding position to strengthen the structure to ensure that the deformation of the plating within the controllable range.

4) in the design to take into account the needs of electroplating process, because the plating working conditions are generally 60 degrees to 70 degrees in the temperature range, under the conditions of hanging, the structure is irrational, deformation is difficult to avoid, so the plastic The design of the location of the nozzle to be concerned about the same time to have a suitable hanging position to prevent the hanging on the surface of the required damage, as shown below, the middle of the square hole designed specifically to hang hang.

5) In addition, it is best not to have metal insert in the plastic parts, due to the expansion coefficient of the two different, in the temperature rise, the plating liquid will penetrate into the gap, the plastic structure caused a certain impact.

4. In the processing of plastic parts, to pay attention to several issues, one of the plastic material in the processing to be fully dried, otherwise the residual moisture on the surface of plastic parts caused by pores, stream lines and other defects, seriously affecting the plating Effect, and try to avoid the use of release agent, because the use of release agent will affect the adhesion of the coating.

Second, the special requirements of electroplating parts design

2-1. Effect of Plating Thickness on Plating Size

The thickness of the plating part is controlled at about 0.02mm according to the ideal condition, but in the actual production, there may be a maximum thickness of 0.08mm. Therefore, in the sliding fit position, the unilateral clearance should be controlled above 0.3mm , In order to achieve satisfactory results, this is our cooperation with the plating when the need for attention.

2-2. Control of deformation of electroplating parts

As the electroplating process, the operating temperature of several processes are in the range of 60 ℃ ~ 70 ℃, in such working conditions, the hanging of the workpiece easily deformed, how to control the deformation of parts is a concern in our processing , In the same electroplating plant after the exchange of engineers that is the key to the plastic structure to fully consider the articulation and support structure of the design, the purpose is to enhance the strength of the entire structure, the general practice is in the injection of the flow structure Design a variety of structures, that is, to ensure that the filling of the plastic flow has strengthened the overall structure, electroplating, together with electroplating, after plating cut the runner to get the final product.

2-3. Implementation of local plating requirements

In our design often requires the different parts of the surface to achieve different effects in the electroplating parts are often such a demand, we usually use the following three methods to achieve this function:

1. If you can separate parts, it is recommended to make different parts, and finally assembled into a part, in the shape is not complicated and the components under the conditions of batch conditions, open a small mold injection costs will form a more obvious price advantage ,

2. If it does not affect the appearance of the local requirements of non-plating, usually can be used after the addition of insulating ink plating method for processing, so that the location of the insulating ink will be coated with metal coating, to meet the requirements, in fact, this is our Design often involves a part, because the electroplated parts will become hard and brittle, we do not want to get the results, so especially in the press on the type of parts it is the arm we do not want to be plated Of the part, because we need it to have full flexibility, local plating at this time is very necessary. In other cases are also commonly used, similar to the PDA of such lightweight products, the general circuit board directly fixed in the plastic shell, in order to prevent the impact of the circuit, usually in contact with the circuit are part of the insulation treatment, At this time the use of ink to the way before the local treatment of plating.

Electroplating design requires local spraying of insulating ink, encountered in the case of the above figure, in order to get the effect shown in the figure (blue and purple that part of the plating), the actual is impossible to achieve, because the plating part of the plating to be formed The connected circuit can form a good electroplating layer for each part, and as shown in the figure, each plating surface is divided into a lot of parts, can not achieve a uniform plating effect.

The above components can eventually be achieved using the above diagram, only to form a good circuit can make the current and the liquid in the good response of the ion in order to achieve a good plating effect.

3. Another way is to use a similar two-color injection molding process, generally if there are two-color injection machine, ABS and PC can be divided into different stages of injection, made of plastic parts after plating treatment, under such conditions, Plastic on the plating solution of the different adhesion led to the part of the ABS has the effect of electroplating and PC part of the plating effect is not to meet the requirements, another way is to divide the parts into two parts, now a part of the injection The electroplating process was carried out and the treated product was reintroduced into another set of molds for secondary injection to obtain a final sample.

2-3. Mixed plating effect on design requirements

We often use high-photo plating and eutectic plating in the design of the effect of a product in a special design effect, usually in the design of the proposed use of smaller etching, so the effect will be better, but this design, In order not to make the effect of etching is covered by plating, and sometimes will not be plated after plating two layers, so the consequences of plating the second layer of nickel will be easier to oxidize discoloration, affecting the design effect.

The effect of plating on the design

Here mainly refers to the color of the plating effect, to submit the color difference table, because the color after plating can not be uniform, different parts will have a greater gap, so to provide an acceptable color gap.

Foaming, black, yellow, exposed copper, exposed substrate, corrosion, electroplating charred, color, hemp, debris,

Size is wrong? But the performance? Poor plating?

You are welcome to contact us

400-633-5198

This is a magic number to help you solve a variety of plating surface treatment problems ~ ~

Long press two-dimensional code "identify" concern

20 years of professional electroplating, electroplating industry leader!

Shenzhen Jinyuan Kang Industrial Co., Ltd

National hi - tech enterprises

Large surface treatment enterprises

Tel: 0755-89924222 89924333

Website: www.jyksz.com

Address: Shenzhen City Pingshan District sand with the rich industrial area

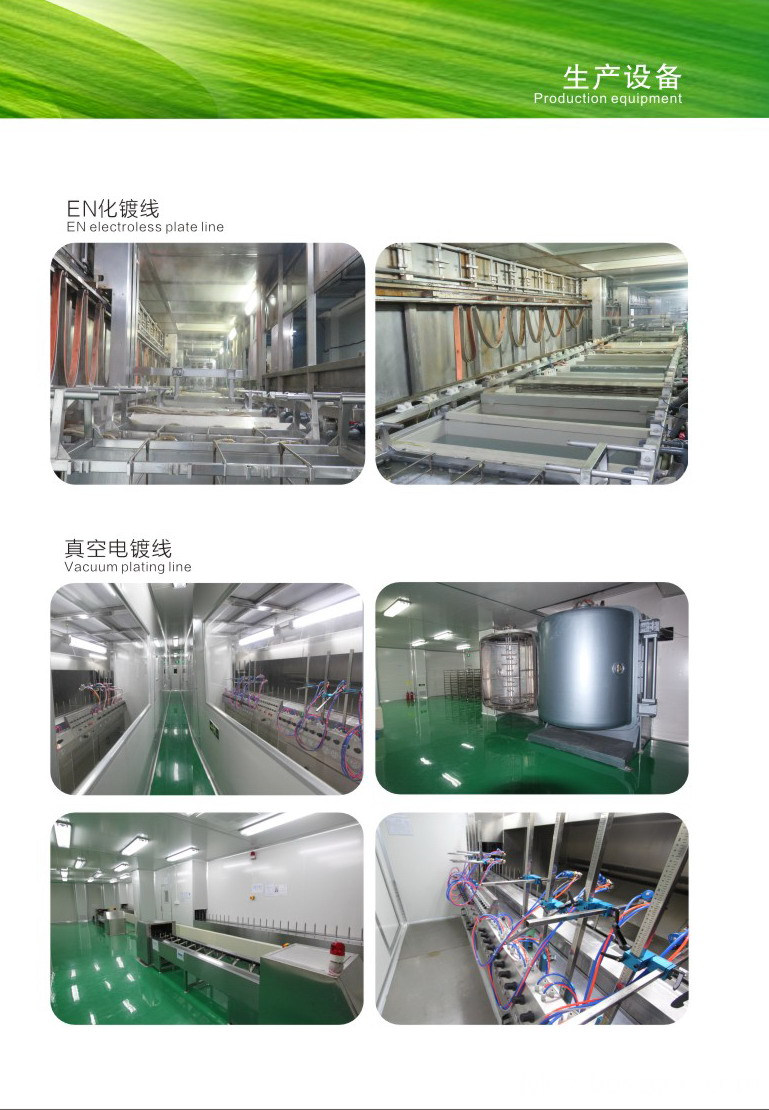

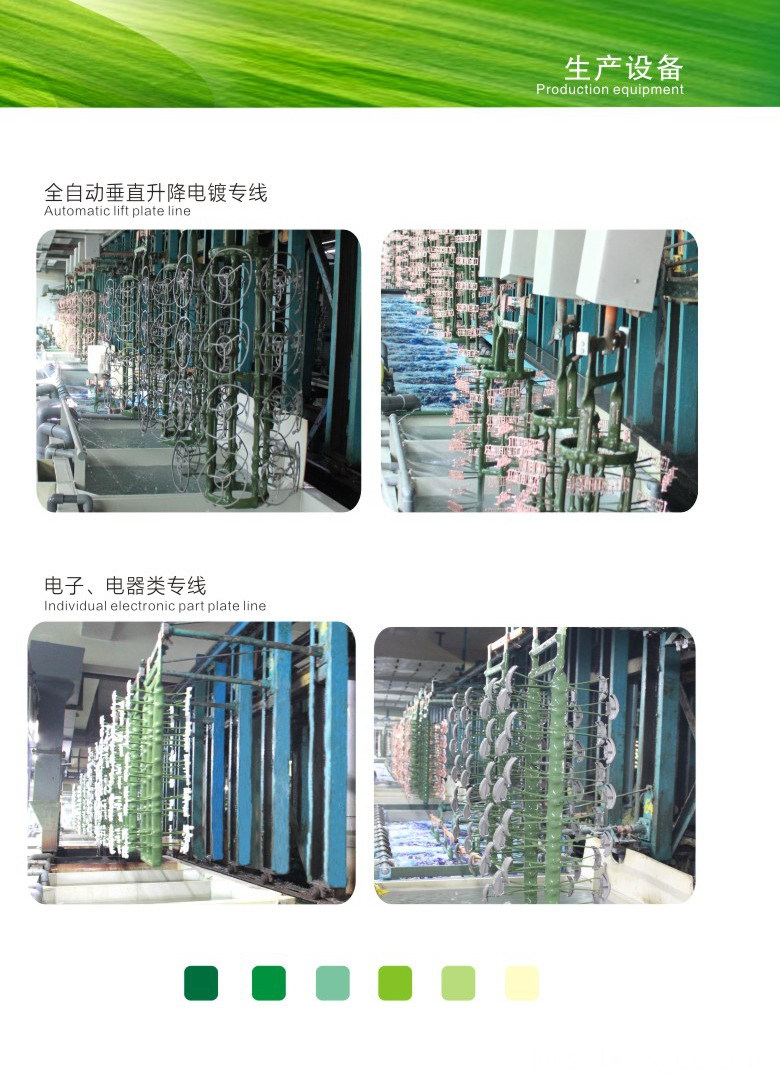

Main: plastic water plating, vacuum plating, metal plating, chemical plating, nano-nickel plating, anodizing, drawing, spraying, laser carving, printing, and plastic molding, and other supporting processing services.

Shenzhen, Guangdong, China

- Manufacturer

- OEM service

- Platform Certification

- The Belt And Road

Send your inquiry to this supplier