1 / 3

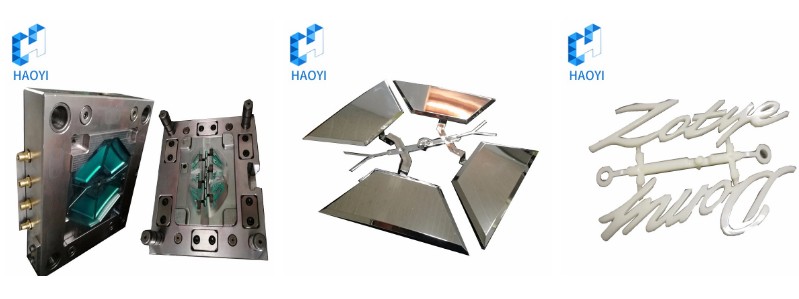

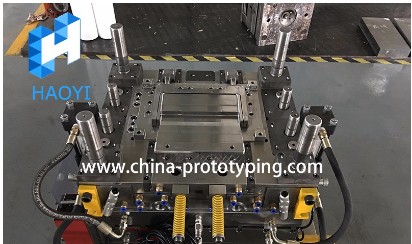

Custom injection mold Custom Car parts Molding Service

| Model No. : | Haoyi-1 |

|---|---|

| Brand Name : | Haoyi |

| File Format : | Step/ Igs /stl/Solid Works / UG |

Product description

Overview: Plastic mould design structure elements to consider are:

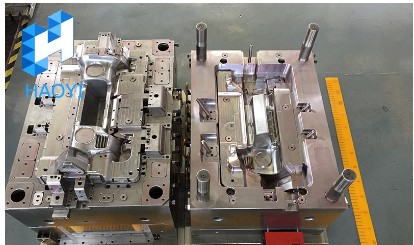

1 the parting surface, i.e., die and punch die closed reciprocal contact surface.Its position and form of selected, the product shape and appearance, wall thickness, molding method, processing technology, mold type and structure, after stripping methods and factors such as molding machine structure.

(2) structure, that is, complex mold slider, inclined top, top piece, etc.Structure design is critical, is related to the life of the mold, the processing cycle, cost, quality, etc., so the design of complex mold core structure on the designer's comprehensive ability the demand is higher, as far as possible the pursuit of more simple, more durable and more economical design.

(3) the mold accuracy, namely from the card, precise positioning, guide pin, positioning pin, etc.Positioning system is related to the appearance quality of the products, mold quality and life expectancy, according to the mould structure is different, choose different way of positioning, rely mainly on machining precision control, internal model is mainly targeted at the designer to consider fully, to design more reasonable and easy to adjust positioning way.

(2) the gating system, that is, by feeding channel between mold and injection molding machine nozzle, including the mainstream way, distributary channel, gate and cold.Especially the selected gate location should be conducive to the molten plastic flows in a good condition with cavity, attached to the products of solid cold runner and sprue feeding when open mold is easy to be out and be removed from the mould (except hot runner mold).

(3) of plastic shrinkage rate, and the factors affected the accuracy of product size, such as mould manufacturing and assembling error, mold wear, etc.In addition, the mold design and injection molding, molding machine should also be considered in the process and structure parameters matching.In the plastic mould has been widely used in the design of computer aided design technology

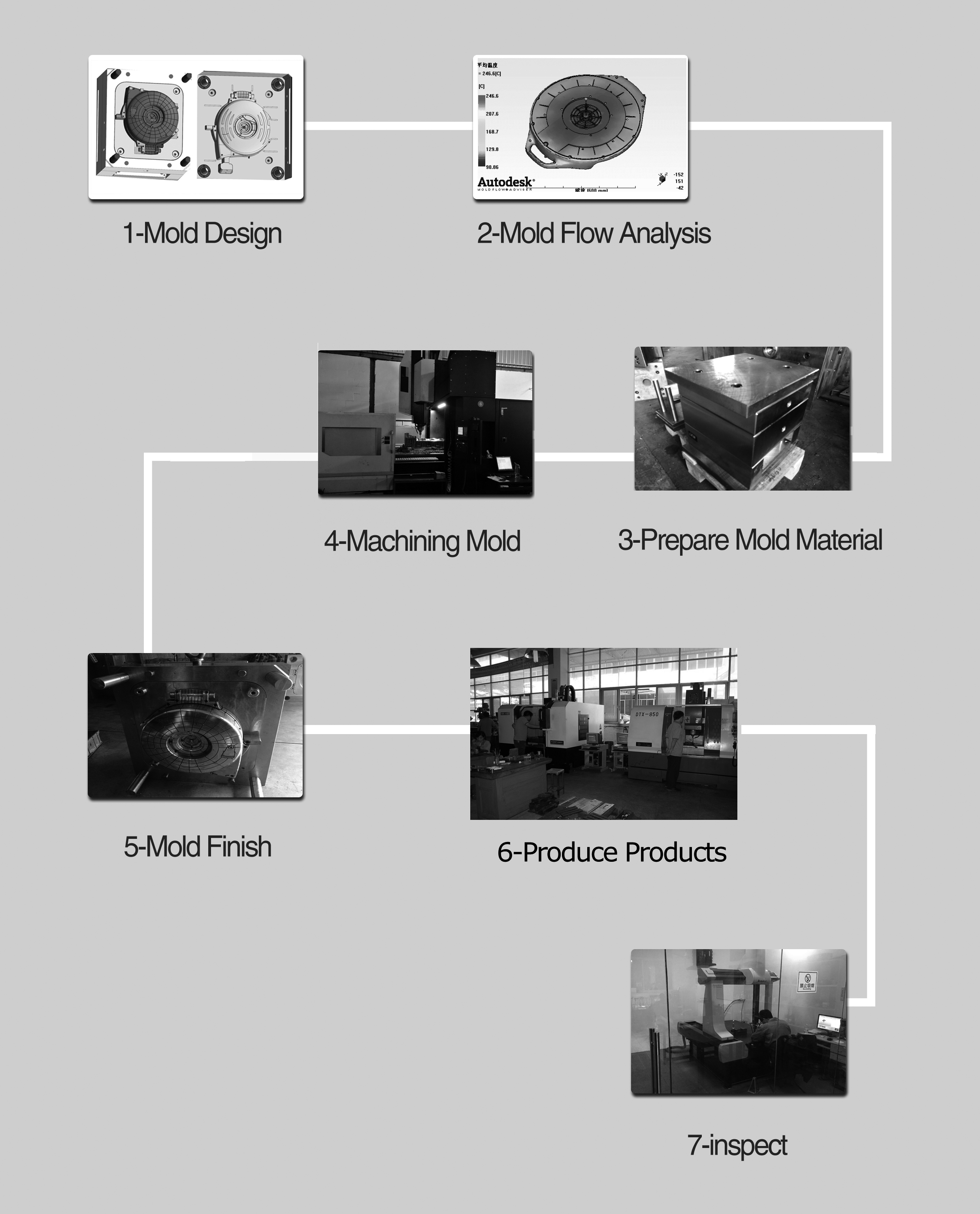

>we will need 3-5 days to make the mold analysis

>Our engineers follow the molds' production every week to make sure all of them are in schedule

>After trial production, we will check the samples to make sure all are right

>We will send the sample and dimension report to our clients for approval

>After everything is ok, we will do final inspection on the molds and products before shipment.

|

Type

|

Custom Injection Mold

|

|

Mold life

|

30000-500,000 shots

|

|

Core&Cavity Material

|

Nak80,P20,H718,S136,SKD61,2738,DC53,H13 ect

|

|

Products Material

|

ABS,PP,PC,PE,PA66,PA6,ect

|

|

File Format

|

Step/ igs /stl/Solid Works / UG

|

|

Runner

|

Hot runner,cold runner

|

|

Delivery Time

|

25-40days for mold,plastic products according to quantity

|

|

Sample lead time

|

About 4-7 weeks, according to the moulding

|

|

Products lead time

|

About 4-6 weeks, According to your order

|

|

Package

|

Standard Export Carton with pallet or as per customes'requirement

|

|

Plastic Injection Machine

|

26sets,90T,138T,160T,168T,200T,260T,320T,400T,488T,1000T

|

|

Mold payment term

|

50%T/T deposit with PO , balance 50% T/T after sample approved

|

|

Products payment term

|

30%T/T deposit with PO, balance 70% T/T before shipment

|

|

Port of loading

|

Ningbo or Shanghai port

|

|

Package

|

Rust-proof protection, fresco bag, wooden case and pallet, suitable for shipment

|

|

|

|

Haoyi have worked with Europe ,America and Southeast Asia over 30 countries and regions in Automobile, daily necessities, home appliances and other area.

Direct or indirect customer coverage of Volkswagen, Skoda, IKEA and so on. We are proud to be recognized by many qualified suppliers of production companies.

Haoyi's professional engineering team strictly control each project from the design, manufacture, sampling, large-scale production to ship, and timely feedback to customers.

Our quality and service is the best proof!

Our Service

> Product Design,Structural Optimization,Process Optimization

> .Mold Making,Plastic Molding Parts

>.Manage Project,Control The Delivery and Quality of Products

>.Arranging the Transportation,Customs Clearance and other Matters for You

Delivery Details : 2-30 days after place order

Q: Can you make the small production with mold?

A: Sure ! quantity is according to the customer

Q:How do we control the mold processing?

A: We will send the processing report and mold processing picture every two week to the

customer.

Q: Is the samples free of charge?

A: Yes, the first trial samples (5-10pcs) is free, and we will send you the samples by DHL, FEDEX or TNT as soon as we finish the first samples.

Q: Who own the mold?

A: Customer

Q:Can I test my idea/component before committing to mould tool manufacture?

A:Yes, we can use CAD drawings to make models for design and functional evaluations.

Q:What type of plastic is best for my design/component?

A: Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Q:I've decided to go ahead with my project. How long will it take to get my parts?

A:It takes 3 - 4 weeks to have the mould tool manufactured depending on the part's complexity and the number of impressions (single or multi). After we have received final approval by you of the new tool, you can expect delivery of parts within 3-5 days.

Send your inquiry to this supplier