Video

1 / 2

CS fiber laser cutting machine for carbon steel

| Model No. : | UT-3015F |

|---|---|

| Brand Name : | UTECH |

| Function : | Metal Cutting |

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

3015 CS fiber laser cutting machine for carbon steel

================> Product introductions <=================

Advantages of Fiber Laser Cutter

1.High Efficiency--The rapid cutting speed is two times higher than normal laser cutting machine.

2.Environment friendly--Laser cutting will not creates any gases for the special cutting technology for steel sheet.

3.Lower Consumption--The power consumption is 20%-30% lower than ordinary laser cutting machine.

4.Maintenance-free--For the fiber laser cutter, the reflect lens are no needed. It will help to save a lot of time when optical path is adjusted. The laser generator with longer lifetime which no need maintaince during usage.

================> Product characteristics <================

1. The world's top fiber lasers and laser power supplies are used. Modular and redundant design; small size, light weight, easy to move;

easy to integrate, stable performance, and the overall quality of the

product is safe.

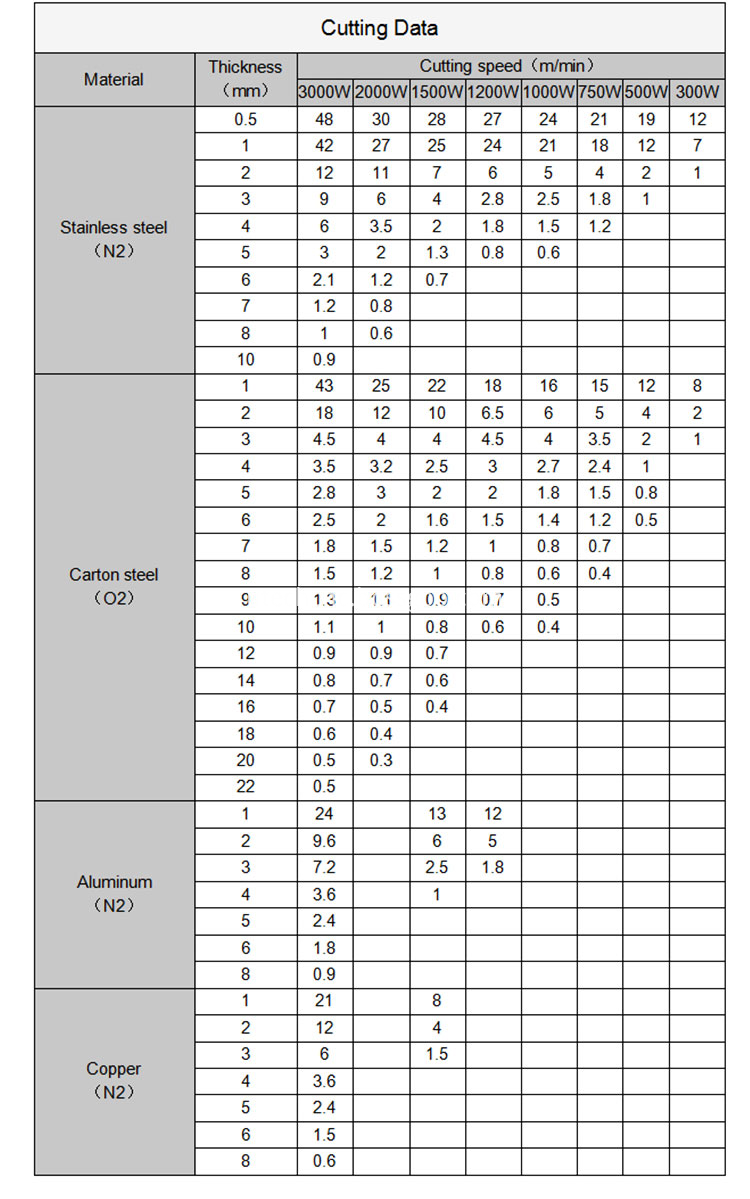

2. An automatic laser head is used. The focus can be adjusted automatically, suitable for a variety of

focal lengths; auto focus function, capacitive sensing, fully automatic

follow-up

system; composite lens, built-in water-cooled structure; double

water-cooled constant temperature for collimation and focusing

components; drawer type lens holder, Replace the protective lens

quickly; smooth and efficient airflow design; adapt to various fiber

lasers; short, long focal length common, can achieve the best cutting

effect of thin or thick plate; all equipped with collimating protective

mirror, better protection collimating mirror; The QBH circumferential

position is adjustable, ensuring that each QBH red dot faces outward,

facilitating the insertion and removal of the fiber head; the focus

position visible window ensures that the input focus is exactly the same

as the output focus.

3. Machine base. The whole cast iron bed is used for better stability and shock resistance and higher cutting quality.

4. Transmission system. It adopts high-precision rack and double-drive transmission and adopts imported servo system to ensure the accuracy of the machine under high-speed motion.

5. It adopts professional PC industrial computer operation, graphical interface, convenient operation, professional cutting control software can freely design all kinds of graphics and text, instant processing, support CAD, CorelDraw and other professional drawing software. 6. WIFI wireless remote control. Equipped with wifi wireless control, remote diagnosis can be realized, which greatly reduces the waste of time and money caused by personnel: by looking at the laser parameters, analyzing the cause of the laser failure; checking the cutting process parameters by the control system software, troubleshooting the cutting fault.

7. High power double cooling water cooler (can refrigerate laser and laser head at the same time). With perfect cooling system, the whole machine operates stably, efficiently and durable.

8. Other main accessories.The imported electric proportional valve provides a strong foundation for the machine to operate for a long time with high precision.

9. High standard production system. Full assembly process inspection, all detection records are kept for customers to check at any time.

10. The whole series is equipped with electronic control cabinet temperature, humidity controller, stable equipment under constant time electronic control system stable operation.

==================> Technical parameters <===============

|

Model |

UT-3015 |

|

Working area |

3000*1500mm |

|

Max moving speed |

100m/min |

|

Max working speed |

1G |

|

PositionaI accuracy |

0.07mm |

|

Repositioning resolution |

0.02mm |

|

Optional working area |

4015/4020/6015/6020/6025 |

|

Laser power |

2000W/1500W/1000W |

|

Cutting thickness |

16mm/12mm/10mm |

==================> Advantages of the Fiber laser cutter <===============

1. High Efficiency--The rapid cutting speed is two times higher than ordinary laser cutting machine.

2. Environment friendly--Laser cutting will not creates any gases for the special cutting technology for steel sheet.

3. Lower Consumption--The power consumption of our fiber laser cutter was reduced by 20%-30% compared wtih ordinary laser cutting machine.

4. Maintenance-free--For the fiber laser cutter, the reflect lens are no needed. It will help to save a lot of time when optical path is adjusted. The laser generator with longer lifetime which no need maintaince during usage.

================> UTECH services <=================

1. Whole machine with one year warranty, within one year, if there has parts broken, you can send back to us, then we'll send a new one to you.

2. Free training course at our plant or on line.

=======================> FAQ <=====================

UTECH is the best choice you can choose.

A. Question: How is 500W CNC Fiber Laser Cutting Machine for Carbon Steel & Stainless Steel guarantee?

Re: a1. 1000W CNC Fiber Laser Cutting Machine for Carbon Steel & Stainless Steel warrenty period is 12 months after BL time;

a2.12 hours technical support feedback;

a3. Own machining factory, which can control the spare parts quality at high quality;

a4. Own accessories warehouse and user can enjoy the agent price.

B. Question: How is delivery time?

Re: We can delivery the machines within 15-25 days if we have the machines in stock.

The

common machine fabricating time is 5-7 days and CNC machine fabricating

time is about 25-45 days.If you have customized products, the delivery

time will be given after confirmation.

C. Question: How is payment?

Re:

50% of amount as deposit and the balance should be paid by T/T or LC at

sight before seller delivery the machines to loading port.

D: Question: What`s the package?

Re:

We have 3 layers package. For the outside, we adopt wood craft case. In

the middle, the machine is covered by foam, to protect the machine from

shaking. For the inside layer, the machine is covered by thickening

plastic bag for waterproof.

E: Question: How can I do if the machine goes wrong?

Re: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else.

If you're interested in our machine, welcome to contact me via following contact ways,

Video

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier