1 / 3

Corner bead angle machine dry wall roll former

| Model No. : | corner bead |

|---|---|

| Brand Name : | jcx |

| Diameter Of Shaft : | 40mm |

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- OEM service

- Platform Certification

- Online Expo

- Video

Product description

Corner bead angle machine dry wall roll former

We supply different kinds of roll forming machine:

Roof Panel Roll Forming Machine

Cz Purlin Roll Forming Machine

High Way Crash Barrier Roll Forming Machine

Light Gauge Framing Machine

Roller Shutter Door Forming Machine

Double Layer Roll Forming Machine

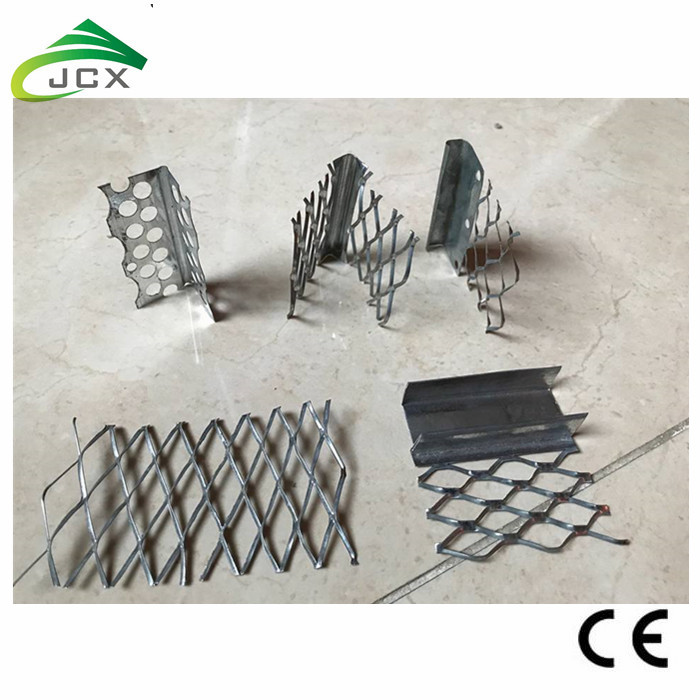

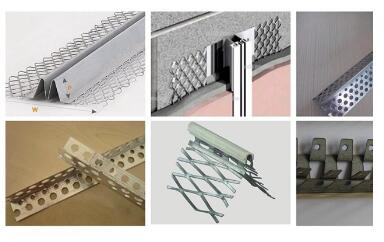

Mesh angle bead is also called corner beads.It is formed from zinc coated steel strip or stainless steel.It is used on the corner of walls,and inside of plaster,on the corner which enables the straightness ,rigidity and long life time for walls.

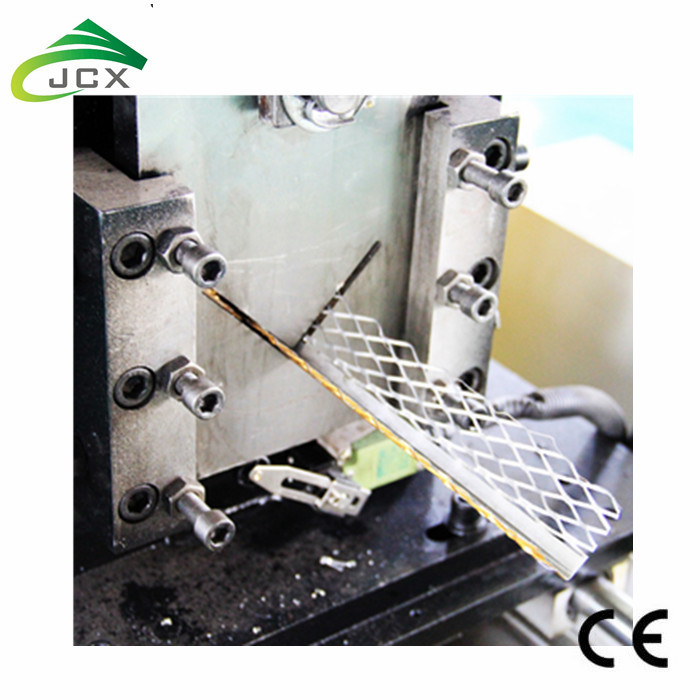

Our Galvanized Drywall Angle Beads Profile Machine is a complete line which can make the mesh corner bead automatically.It designed for production angle beads with mesh punching.The final product can be cut as per set length controller,and the length is automatically measured by encoder.When final product reached set length,machine will stop to cut the sheet automatically.Finish thhis action,the machine will run again continuously.It is composed of electric decoiler, punching machine,mesh punching dies,main forming,automatic cutting.

1.Component of angle bead forming machine

1) Manual decoiler set 1

2) Main forming machine set 1

3) PLC control system set 1

4) Hydraulic pump station set 1

5) Post cut set 1

6) Electric motor set 1

7) Output table set 1

8)Punching system 1

2.ANGLE BEAD MACHINE/CORNER BEAD MACHINE TECHNICAL PARAMETER

1) Length of the main part 3000*800*1400mm

2) Weight of main part About 3 t

3) Voltage 380V/50HZ3Phase (as customer`s request)

4) Roller fixer Guide column

5) Frame Middle plate welded, Memorial arch frame type

6 Frame thickness 25mm

7 Drive mode Gear or chain

8) Material of rollers 45# steel with tempering

9) Material of shafts 45# steel with tempering

10) Diameter of shafts φ40mm

11) Number of rollers 10 rollers

12) Main power 3kw (Cycloidal planetary gear speed reducer)

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- OEM service

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier