Video

1 / 6

Connecting Components for Medical Instruments

$15.00

≥1000 Piece/Pieces

$14.80

≥5000 Piece/Pieces

| Model No. : | ETOP-2005 |

|---|---|

| Brand Name : | NA |

| place of origin : | China |

Dongguan, Guangdong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Connecting Components for Medical Instruments

The goods are genuine and for you, the voltage is stable and not easy to get hot. Durable and flexible to use. The oxygen-free copper wire has moderate flexibility and is not afraid of various construction environments. We respond quickly to customer needs, take customer needs as the guide, support customized processing according to drawings, and a one-stop procurement platform for mold standard parts. We strive to control production costs.

We have developed a tradition of high-tech engineering, prototyping, and quality custom cable ASSY manufacturing at very competitive pricing. Also with professional flow chart (wire cutting-stripping-copper twisting-crimping-crimping 100% inspection-soldering-molding-asssembling-braiding-testing-FQC100% -OQC) , which can help us support customers with stable quality.

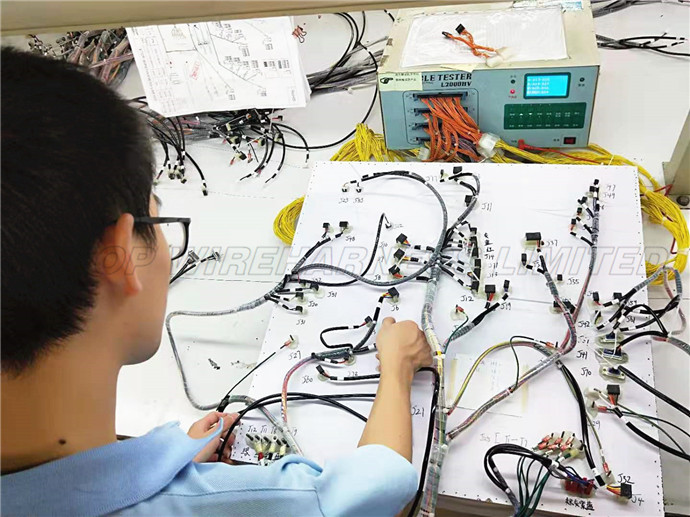

1, The complete loom covered by spiral banding sleeve for protection, also together with PVC tube and heat-shrink tube. Each connector and pin layout marked with heat-shrink tube. spiral tube guarantee the cable flexible enough. This complicated cable assemblies is special assembled with PANCON terminal block connectors, each branch marked with label for distinguish. The complete loom assembled on fixture by covering with PVC tube, spiral tube and tape. which purpose to make sure the loom is flexible enough. These block connectors are MAS-CON® .100" IDC Wire to Board Connector System, available in various type, straight and right angle.

2)For sampling, we make fixture on wooden board to fix size for sampling. During MASS production, we would make formal fixture by metal type, more reliable for quality and testing, also the size. such complicated wire assembly product, assembling them can be a daunting task. With numerous sizes, lengths and colors of wire, cable, connectors, terminal blocks and other components to choose from, it’s similar to putting together a giant jigsaw puzzle.

Harness boards, fixtures and workbenches can make the job easier and less stressful. They all play a critical role in error-free assembly, quick response and continuous improvement.

The front-end of most wire processing applications is highly automated. Indeed, automatic wire cutters, markers, splicers, strippers, wrappers and other production equipment is commonly used by manufacturers to boost throughput and ensure consistent quality.

3) We supported customer to tranfer their simple drawing to production type formal drawing. More content and details would be difined and confirmed. Now harness assemblers face several challenges today, such as:

Being cost-competitive and profitable.

Being flexible to accommodate high-mix, low-volume applications.

Moving quickly from one job to another with minimal downtime.

Dealing with short lead times from customers and just-in-time delivery requirements, without holding too much inventory because of costs or the risk of engineering changes.

Improving ergonomics to reduce repetitive motion disorders and healthcare claims.

Finding qualified workers and retaining them.

With raw material prices and labor variables increasing, finding more efficient and cost-effective methods of assembly are critical. so our engineer try to d prototype to find out the best workable solution to move on mass production. Take all raw materials and assembling skill into consideration.

These compliated wire assemblies used for diagnostic instruments system, special for medical industry.

We specialize in custom harnesses for the widest diversity of cable and connector types, across the whole spectrum of industries. We built your unique Cable Assemblies according to your specified shapes, sizes, pin configuration and cable materials to suit Ethernet, Automation, Marine, Transportation Applications…etc. Now, we produced much complex cable assemblies for medical industry customers. We introduced X-RAY machine to double confirm stable and reliable quality for these cables

Video

Dongguan, Guangdong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier