1 / 4

Complete Welding Equipment for Concrete Mixer and Truck Trial Tanks

| Model No. : | Complete Welding Equipment for Concrete Mixer and Truck Trial Tanks |

|---|---|

| Brand Name : | HUAFEI |

Product description

Key type longitudinal welding machine

Key type longitudinal welding machine  Mainly used for flat stitching longitudinal seam automatic welding, the welding process can be TIG / MIG / MAG / PWA / SAW and other methods for welding carbon steel, stainless steel, aluminum and aluminum alloys, titanium and other materials, widely used the aerospace, automotive parts, motorcycles, home appliances, pressure vessels and food machinery industry. Pneumatic compression device key structure to ensure uniformity of the work piece clamping, mandrel optional water-cooled and back seam gas protection, reduce welding deformation; control system uses PLC + touch interface humane and effective to ensure the welding quality, simple and reliable operation Main parameter

Mainly used for flat stitching longitudinal seam automatic welding, the welding process can be TIG / MIG / MAG / PWA / SAW and other methods for welding carbon steel, stainless steel, aluminum and aluminum alloys, titanium and other materials, widely used the aerospace, automotive parts, motorcycles, home appliances, pressure vessels and food machinery industry. Pneumatic compression device key structure to ensure uniformity of the work piece clamping, mandrel optional water-cooled and back seam gas protection, reduce welding deformation; control system uses PLC + touch interface humane and effective to ensure the welding quality, simple and reliable operation Main parameter Model | PB-3000 | PB-4500 | PB-6000 | PB-9000 | |

Work piece length(mm) | ≤3900 | ≤4500 | ≤6000 | ≤9000 | |

Work piece thickness(mm) | 3.0-8.0 | ||||

Welding head walking speed(mm/M) | 0-4000 (or according to customer demand) | ||||

Welding torch lift stroke(mm) | 100 | 250 | |||

Welding torch fine turning stroke (mm) | Y=100,Z=100 | ||||

Controller power | Single-phase AC220v 50Hz | ||||

The longitudinal seam welding machine is mainly composed CZ3× 3 Operating manual rotary machine, "7" shape welded frame (plus copper pad), the work piece carriage, NBC500 gas shielded welding power source (including wire feeder, wiring, etc.), BDQ- composed of a welding oscillator and other parts, mainly for the tapered cylinder outer longitudinal weld seam. The main working steps: n The work piece is placed on the cantilever bracket welded to quickly find the welds through a dedicated ruler; n Bracket holding the work piece put in welding place; n By operating the welding manipulator boom’s telescopic are to complete the seam welding; n During welding weld oscillator swing so can ensure weld seam even and appearance, copper liner was put in cantilever bracket conducive to the formation of welding. Long shaft rotator and the group of Squirrel tool

The longitudinal seam welding machine is mainly composed CZ3× 3 Operating manual rotary machine, "7" shape welded frame (plus copper pad), the work piece carriage, NBC500 gas shielded welding power source (including wire feeder, wiring, etc.), BDQ- composed of a welding oscillator and other parts, mainly for the tapered cylinder outer longitudinal weld seam. The main working steps: n The work piece is placed on the cantilever bracket welded to quickly find the welds through a dedicated ruler; n Bracket holding the work piece put in welding place; n By operating the welding manipulator boom’s telescopic are to complete the seam welding; n During welding weld oscillator swing so can ensure weld seam even and appearance, copper liner was put in cantilever bracket conducive to the formation of welding. Long shaft rotator and the group of Squirrel tool

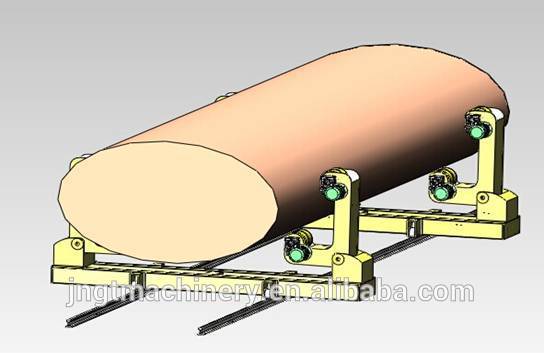

1. Structure: the whole or segmental structures; for 8-16 cubic meters tank;

1. Structure: the whole or segmental structures; for 8-16 cubic meters tank;2. Mainly used for cement mixer cylinder group welding; cylinder diameter range of ø1800-2600mm, two roller center distance adjustable 3. Load 5-20 tons; the length of the drum 6000-10000mm; drum diameter ø260-325 mm

4. Adopting AC frequency conversion speed control; and with remote operation box

5. Smooth operation after loading, speed regulating is reliable; the connection between reducer and rotator is connected with a transmission shaft (Universal) 6. Drive mode: two rolls simultaneously driving; drive type: AC motor;

7. Fixed frame, chassis plate is welded, annealing after weld, to remove stress

8. The squirrel cage tooling is annealing treated after welding, connecting surface finishing, good stiffness, high group precision Barrel circular welding center

The circular seam welding machine is mainly composed of CZ44 electric walking electric rotary welding manipulator, ZTX-10T special welding rotator, NBC-500 IGBT gas shielded welding machine, welding car, etc. mainly used for outer circular seam welding of tank and vessel. The machine usually put beside wall. The main work steps: n Put the work piece on ZTX-10T welding rotator; n Align the start position of the welding seam through the travel and boom extension function of the welding manipulator; n Welding rotator rotates, start arc welding; n Judge welding seam offset according to the indicator, real-time adjust welding torch offset by fine tuning slider; n Welding finish, press the stop button, welding arc extinguishing, welding rotator stop rotate. Storage tank 2. Storage tank welding equipment.

The circular seam welding machine is mainly composed of CZ44 electric walking electric rotary welding manipulator, ZTX-10T special welding rotator, NBC-500 IGBT gas shielded welding machine, welding car, etc. mainly used for outer circular seam welding of tank and vessel. The machine usually put beside wall. The main work steps: n Put the work piece on ZTX-10T welding rotator; n Align the start position of the welding seam through the travel and boom extension function of the welding manipulator; n Welding rotator rotates, start arc welding; n Judge welding seam offset according to the indicator, real-time adjust welding torch offset by fine tuning slider; n Welding finish, press the stop button, welding arc extinguishing, welding rotator stop rotate. Storage tank 2. Storage tank welding equipment.  Special shape vessel positioner

Special shape vessel positioner  welding process in the procedure of the tank manufacturing, make the tank and fixture welded together, fixed on the worktable of the positioner, so that the frame can be 360 degrees do any flip, in the process of welding, vertical welding, overhead welding seam, can change into flat welding fast after shift position, so that make the heavy welding work more humanization, reduce the labor intensity of workers, make the welding site more secure and standard, so as to ensure the welding quality, improve the efficiency of welding, ensure employee’ safety. Main technical parameter Loading capacity: 5000kg Work piece length: 5000-20000mm Work piece width: 3600 Worktable tilt angle: 360°×n Worktable tilting speed: 0.4r/min~1.5r/min,Rotary drive frequency conversion stepless speed regulation, in the range of speed, fluctuation of rotate speed is not more than 5% when bearing maximum loading Max. Eccentricity: 200mm Rotate center height: ≥1700mm(on base of ground) Welding current : 1000 A Special shape tank self-adjustable welding rotator

welding process in the procedure of the tank manufacturing, make the tank and fixture welded together, fixed on the worktable of the positioner, so that the frame can be 360 degrees do any flip, in the process of welding, vertical welding, overhead welding seam, can change into flat welding fast after shift position, so that make the heavy welding work more humanization, reduce the labor intensity of workers, make the welding site more secure and standard, so as to ensure the welding quality, improve the efficiency of welding, ensure employee’ safety. Main technical parameter Loading capacity: 5000kg Work piece length: 5000-20000mm Work piece width: 3600 Worktable tilt angle: 360°×n Worktable tilting speed: 0.4r/min~1.5r/min,Rotary drive frequency conversion stepless speed regulation, in the range of speed, fluctuation of rotate speed is not more than 5% when bearing maximum loading Max. Eccentricity: 200mm Rotate center height: ≥1700mm(on base of ground) Welding current : 1000 A Special shape tank self-adjustable welding rotator  Main technical parameter

Main technical parameter Model No. | GRJ-10 |

2 Initiative load capacity | 10T |

Roller base adjust mode | Screw stepless regulation |

Roller liner speed | 200-1000mm/min (Frequency stepless speed adjustment) |

Motor power | 8×1.1KW |

Vessel diameter | φ1100-2600 |

Roller surface material | Polyurethane |

Roller dia. | φ250mm |

Roller width | 300mm |

Inner distance of rail | 1500mm |

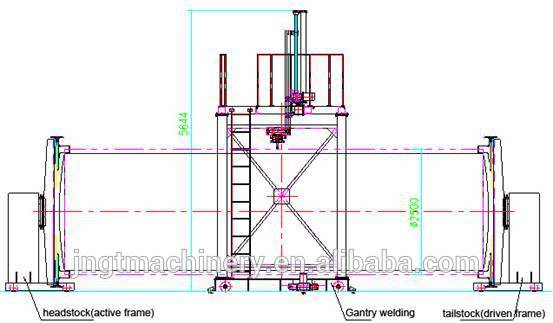

Welding process: 1). Tank longitudinal seam welding A. Align the start position of the welding seam through the travel of gantry frame and slide plate moving; B. Gantry frame travel (travel speed change to frequency stepless speed regulation), start longitudinal seam welding, Operator adjust the welding seam offset in real time manually. Welding head is with welding oscillator, can be used when required. 2). Tank Circular seam welding A. Align the axle center position of the welding seam through the travel of gantry frame and slide plate moving; B. Welding positioner drive work piece rotate to finish seam welding, mechanical tracking device adjust the angle and height of welding gun automatically, real-time tracking of work piece surface; and the mechanical tracking device capable of weld in the axial offset can be automatic fine tuning. C. work piece rotary speed can be adjusted automatically, to meet the requirement of welding. D. head with a welding oscillator can be used when needed. Main Technical Parameter

Welding process: 1). Tank longitudinal seam welding A. Align the start position of the welding seam through the travel of gantry frame and slide plate moving; B. Gantry frame travel (travel speed change to frequency stepless speed regulation), start longitudinal seam welding, Operator adjust the welding seam offset in real time manually. Welding head is with welding oscillator, can be used when required. 2). Tank Circular seam welding A. Align the axle center position of the welding seam through the travel of gantry frame and slide plate moving; B. Welding positioner drive work piece rotate to finish seam welding, mechanical tracking device adjust the angle and height of welding gun automatically, real-time tracking of work piece surface; and the mechanical tracking device capable of weld in the axial offset can be automatic fine tuning. C. work piece rotary speed can be adjusted automatically, to meet the requirement of welding. D. head with a welding oscillator can be used when needed. Main Technical Parameter Model No. | LZM-4.0 |

Gantry trolley travel speed | 220-2200mm/min (infinite speed variation) |

Torch horizontal moving speed | 2200mm/min |

Torch lifting speed | 390mm/min |

Torch lifting stroke | 1500mm |

Guide rail center distance | 4200mm |

Guide rail specification | 24kg (precision type) |

Guide rail length | 36m×2 |

Input power | three phase four wire system 380V/50Hz |

Main technical parameter: 1) Height of gantry frame(distance between beam and ground) 1.2m 2) Torch lifting stroke(Up Down) 200mm 3) Torch longitudinal travel 700mm 4) Gantry frame travel motor power 0.75KW×2 5) Gantry frame travel welding speed 250-1200mm/min 6) Fast return speed 2880mm/min 7) Gantry frame Guide rail center distance: 3m (user prepare) 8) Length of guide rail Customizable Chain Turnover machine Main Technical parameter

Main technical parameter: 1) Height of gantry frame(distance between beam and ground) 1.2m 2) Torch lifting stroke(Up Down) 200mm 3) Torch longitudinal travel 700mm 4) Gantry frame travel motor power 0.75KW×2 5) Gantry frame travel welding speed 250-1200mm/min 6) Fast return speed 2880mm/min 7) Gantry frame Guide rail center distance: 3m (user prepare) 8) Length of guide rail Customizable Chain Turnover machine Main Technical parameter Item | Technical data |

Size of work piece L x W (Max.) | 3800×3800mm |

Length of work piece | 7000—14000mm |

Turnover mode | Chain |

Total power | 9KW |

Hoisting speed | About 1500mm/min |

R & L center distance of column | 4500mm |

F & B center distance of column | 6000mm |

Tilting angle | 0°—360° |

Driven method | Conical braking motor + cycloidal reducer |

Max. loading weight | 15000Kg |

Operate mode | remote control (can work individual or simultaneous) |

Column model no. | Welded steel plate |

Chain specification | 18/64 |

After-sale service ♥ Warranty : one year ♥ Engineers available to serve machine overseas ♥ Strict factory inspection ♥ Complete equipment manual ♥ Online instruction ♥ Provide all components, spare parts and consumptive material FAQ Service Purpose: Our professional sale and after-sale service give you a faithful feel. Thanks for your inquiry and welcome to visit our company. Any question, please feel free to contact us!

After-sale service ♥ Warranty : one year ♥ Engineers available to serve machine overseas ♥ Strict factory inspection ♥ Complete equipment manual ♥ Online instruction ♥ Provide all components, spare parts and consumptive material FAQ Service Purpose: Our professional sale and after-sale service give you a faithful feel. Thanks for your inquiry and welcome to visit our company. Any question, please feel free to contact us! Send your inquiry to this supplier