1 / 4

Chemical Vapor Deposition Diamond CVD

Get Latest Price

Send Inquiry

| Model No. : | CVDD-T |

|---|---|

| Brand Name : | Supower |

Beijing World Super Hard Tools Co., Ltd.

You might also like

Product description

CVD Diamond:

Being the largest manufacturer in China, Worldia offers an extensive range of CVD diamond line of products lines. The skills of diamond film growing technology developed by Worldia, lapping , polishing, laser cutting and own many patents in the thick film-supported CVD diamond material producing and processing field. Application: Worldia Chemical Vapor Deposition Diamond CVD Diamond can be used in machine cutters, diamond dressers, diamond wire drawing die blanks, electronic components heat spreaders and other fields.

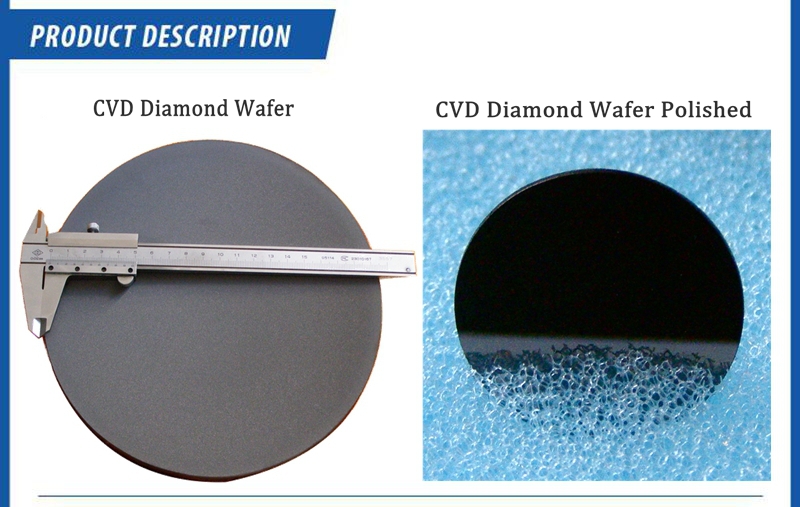

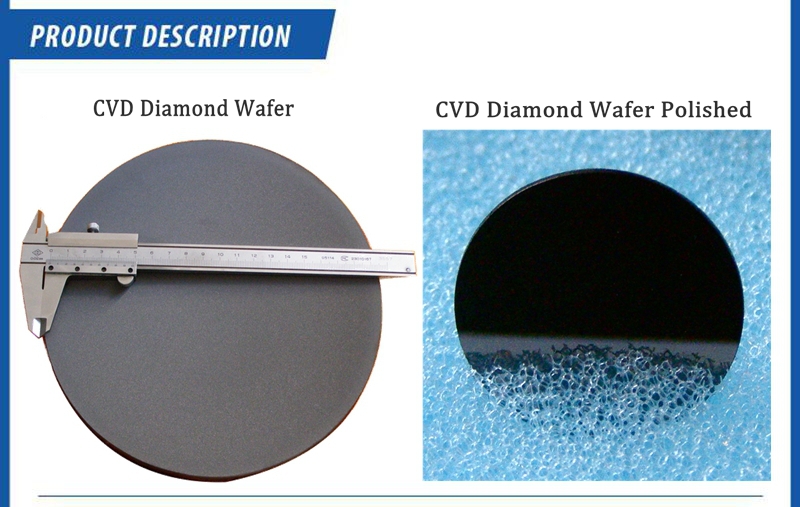

CVD Diamond Products Series 1. CVD Diamond Wafer: According to different use, Supower can meet the customers' extent needs in abrasion ratio, fracture resistance, purity, and thermal conductivity, and so on. Supower CVD diamond wear resistant parts and coating tools can increase all kinds of products using life. Supower supply no-processed CVD diamond blanks, and customers can lap or cut them according to their particular needs. Specification: 0.3-3 mm thick, the max diameter is 200 mm. 2. CVD Diamond Heat Sinks: By now, diamond is the most heat conductive material, and the heat conductivity in normal temperature is 2000WK-1 m-1, which is 5 times as much as cooper, even the heat conductivity is 1000WK-1 m-1, it also can be 4-6 times as much as normal ceramics. In heat management, natural diamond is used in some parts of microwave and laser diode. Because of limited resource, dimension and high cost, it hasn’t been used widely. Today the CVD diamond made by Vapor Deposition has the similar thermal the diamond dimension limited problem. 3. CVD Diamond Dresser Logs: Truing and dressing are playing a vital role in today's grinding process, and their purposes are to remove dull grits, improve wheel sharpness and concentricity and shape of the wheels. Being the largest manufacturer in China, Worldia offers an extensive range of CVD diamond logs and cubes to the diamond dressing applications. Advantages: Excellent in hardness, sharpness and thermal stability. Un-beatable availability in shape and size. Highly consistent, foresee-able and control-able in quality control. Much ease in the manufacture and use of dressing tools Applications: CVD diamond dresser Logs can be made into single and multi-point dressers, shaped tools for form and profile, diamond dressing rollers, etc. Typical Specifications:

CVD Diamond Products Series 1. CVD Diamond Wafer: According to different use, Supower can meet the customers' extent needs in abrasion ratio, fracture resistance, purity, and thermal conductivity, and so on. Supower CVD diamond wear resistant parts and coating tools can increase all kinds of products using life. Supower supply no-processed CVD diamond blanks, and customers can lap or cut them according to their particular needs. Specification: 0.3-3 mm thick, the max diameter is 200 mm. 2. CVD Diamond Heat Sinks: By now, diamond is the most heat conductive material, and the heat conductivity in normal temperature is 2000WK-1 m-1, which is 5 times as much as cooper, even the heat conductivity is 1000WK-1 m-1, it also can be 4-6 times as much as normal ceramics. In heat management, natural diamond is used in some parts of microwave and laser diode. Because of limited resource, dimension and high cost, it hasn’t been used widely. Today the CVD diamond made by Vapor Deposition has the similar thermal the diamond dimension limited problem. 3. CVD Diamond Dresser Logs: Truing and dressing are playing a vital role in today's grinding process, and their purposes are to remove dull grits, improve wheel sharpness and concentricity and shape of the wheels. Being the largest manufacturer in China, Worldia offers an extensive range of CVD diamond logs and cubes to the diamond dressing applications. Advantages: Excellent in hardness, sharpness and thermal stability. Un-beatable availability in shape and size. Highly consistent, foresee-able and control-able in quality control. Much ease in the manufacture and use of dressing tools Applications: CVD diamond dresser Logs can be made into single and multi-point dressers, shaped tools for form and profile, diamond dressing rollers, etc. Typical Specifications:

Notes: The letter T indicates the thickness of CVD diamond materials, say from the nucleation side to the growth side. The above is only a short list of standard sizes available, additional sizes like triangle and trapezoid are also available upon request. Normally, Worldia has several hundred specifications of CVD diamond logs in stock. The tolerance of standard dresser log product is +/- 0.05mm, while we can control the tolerance within +/- 0.025mm upon request. The production lead time is normally 4 to 8 days, and some of the items may be shipped within 2 work days upon the payment is confirmed. 4. CVD Diamond Dresser Cubes: Truing and dressing are playing a vital role in today's grinding process, and their purposes are to remove dull grits, improve wheel sharpness and concentricity and shape of the wheels. Being the largest manufacturer in China, Worldia offers an extensive range of CVD diamond cubes to the diamond dressing applications. Advantages: Excellent in hardness, sharpness and thermal stability. Un-beatable availability in shape and size. Highly consistent, foresee-able and control-able in quality control. Much ease in the manufacture and use of dressing tools Typical Specifications and Applications

Notes The above is only a short list of standard sizes available, additional sizes are also available upon request. In general, thick-film CVD diamond Cubes are neither side-lapped, please specify if special requirement is needed. The production lead time is normally 4 to 8 days, and some of the items may be shipped within 2 work days upon the payment is confirmed. 5. CVD Diamond Tips: With the rapid development of the manufacturing industry, new technologies such as high-speed machining, dry machining and turning instead of grinding emerge continuously, which put forward higher requirements to the performance of cutting tools. Based on this, CVD diamond turns out to be an ideal solution for cutting tool applications, especially in continuous and finish machining. Advantages Excellent in hardness, sharpness and thermal stability. Higher chemical inertness, superior edge quality. Highly consistent, foresee-able and control-able in quality control. Packaging:

Our CVD diamond products use plastic case for packing. Quality control:

We have dedicated team of quality control and precise equipment to keep good and stable performance for our productsand processing services. OEM/ODM Service: We can customize CVD diamond as you wish, and laser markings as required. Contact : As a specialized CVD diamond lines of product manufacturer and supplier in China, WORLDIA are devoted to be the leading company in area of CVD diamond products manufacturing, and we are committed to provide our customers with cost effective, high performance and high standard CVDD products.

Being the largest manufacturer in China, Worldia offers an extensive range of CVD diamond line of products lines. The skills of diamond film growing technology developed by Worldia, lapping , polishing, laser cutting and own many patents in the thick film-supported CVD diamond material producing and processing field. Application: Worldia Chemical Vapor Deposition Diamond CVD Diamond can be used in machine cutters, diamond dressers, diamond wire drawing die blanks, electronic components heat spreaders and other fields.

CVD Diamond Products Series 1. CVD Diamond Wafer: According to different use, Supower can meet the customers' extent needs in abrasion ratio, fracture resistance, purity, and thermal conductivity, and so on. Supower CVD diamond wear resistant parts and coating tools can increase all kinds of products using life. Supower supply no-processed CVD diamond blanks, and customers can lap or cut them according to their particular needs. Specification: 0.3-3 mm thick, the max diameter is 200 mm. 2. CVD Diamond Heat Sinks: By now, diamond is the most heat conductive material, and the heat conductivity in normal temperature is 2000WK-1 m-1, which is 5 times as much as cooper, even the heat conductivity is 1000WK-1 m-1, it also can be 4-6 times as much as normal ceramics. In heat management, natural diamond is used in some parts of microwave and laser diode. Because of limited resource, dimension and high cost, it hasn’t been used widely. Today the CVD diamond made by Vapor Deposition has the similar thermal the diamond dimension limited problem. 3. CVD Diamond Dresser Logs: Truing and dressing are playing a vital role in today's grinding process, and their purposes are to remove dull grits, improve wheel sharpness and concentricity and shape of the wheels. Being the largest manufacturer in China, Worldia offers an extensive range of CVD diamond logs and cubes to the diamond dressing applications. Advantages: Excellent in hardness, sharpness and thermal stability. Un-beatable availability in shape and size. Highly consistent, foresee-able and control-able in quality control. Much ease in the manufacture and use of dressing tools Applications: CVD diamond dresser Logs can be made into single and multi-point dressers, shaped tools for form and profile, diamond dressing rollers, etc. Typical Specifications:

CVD Diamond Products Series 1. CVD Diamond Wafer: According to different use, Supower can meet the customers' extent needs in abrasion ratio, fracture resistance, purity, and thermal conductivity, and so on. Supower CVD diamond wear resistant parts and coating tools can increase all kinds of products using life. Supower supply no-processed CVD diamond blanks, and customers can lap or cut them according to their particular needs. Specification: 0.3-3 mm thick, the max diameter is 200 mm. 2. CVD Diamond Heat Sinks: By now, diamond is the most heat conductive material, and the heat conductivity in normal temperature is 2000WK-1 m-1, which is 5 times as much as cooper, even the heat conductivity is 1000WK-1 m-1, it also can be 4-6 times as much as normal ceramics. In heat management, natural diamond is used in some parts of microwave and laser diode. Because of limited resource, dimension and high cost, it hasn’t been used widely. Today the CVD diamond made by Vapor Deposition has the similar thermal the diamond dimension limited problem. 3. CVD Diamond Dresser Logs: Truing and dressing are playing a vital role in today's grinding process, and their purposes are to remove dull grits, improve wheel sharpness and concentricity and shape of the wheels. Being the largest manufacturer in China, Worldia offers an extensive range of CVD diamond logs and cubes to the diamond dressing applications. Advantages: Excellent in hardness, sharpness and thermal stability. Un-beatable availability in shape and size. Highly consistent, foresee-able and control-able in quality control. Much ease in the manufacture and use of dressing tools Applications: CVD diamond dresser Logs can be made into single and multi-point dressers, shaped tools for form and profile, diamond dressing rollers, etc. Typical Specifications: 5.0*0.2*0.2t | 8.0*0.5*0.5t | 3.0*1.0*0.8t | 5.0*2.0*1.0t | 5.0*1.3*1.3t |

2.5*0.5*0.3t | 5.0*1.0*0.5t | 2.5*1.3*0.8t | 4.0*1.5*1.0t | 2.0*1.5*1.5t |

3.0*1.0*0.3t | 2.0*0.6*0.6t | 5.0*0.9*0.9t | 5.0*1.1*1.1t | 4.0*1.5*1.5t |

10.0*3.5*0.3t | 5.0*0.7*0.7t | 3.0*1.0*1.0t | 1.5*1.2*1.2t | 4.0*2.8*1.5t |

2.0*0.4*0.4t | 1.5*0.8*0.8t | 8.0*1.0*1.0t | 2.0*1.2*1.2t | 2.0*2.0*1.8t |

5.0*0.6*0.4t | 4.5*0.8*0.8t | 10.0*1.0*1.0t | 5.0*1.2*1.2 | 3.0*2.0*2.0t |

1.5*0.5*0.5t | 10.0*0.8*0.8t | 3.0*1.5*1.0t | 4.0*1.3*1.3t | 3.0*3.0*2.5t |

Specifications | Tolerances | Applications |

0.6*0.6*0.6 | +/- 0.05mm | Dressing Rollers |

0.8*0.8*0.8 | ||

1.0*1.0*1.0 | +/- 0.08mm | Single and Multi-point Dressers |

1.2*1.2*1.2 | ||

1.5*1.5*1.5 | +/- 0.10mm | |

1.8*1.8*1.8 | ||

2.0*2.0*2.0 | ||

2.2*2.2*2.2 | ||

2.5*2.5*2.5 |

Our CVD diamond products use plastic case for packing. Quality control:

We have dedicated team of quality control and precise equipment to keep good and stable performance for our productsand processing services. OEM/ODM Service: We can customize CVD diamond as you wish, and laser markings as required. Contact : As a specialized CVD diamond lines of product manufacturer and supplier in China, WORLDIA are devoted to be the leading company in area of CVD diamond products manufacturing, and we are committed to provide our customers with cost effective, high performance and high standard CVDD products.

Send your inquiry to this supplier

Send Inquiry