Video

1 / 7

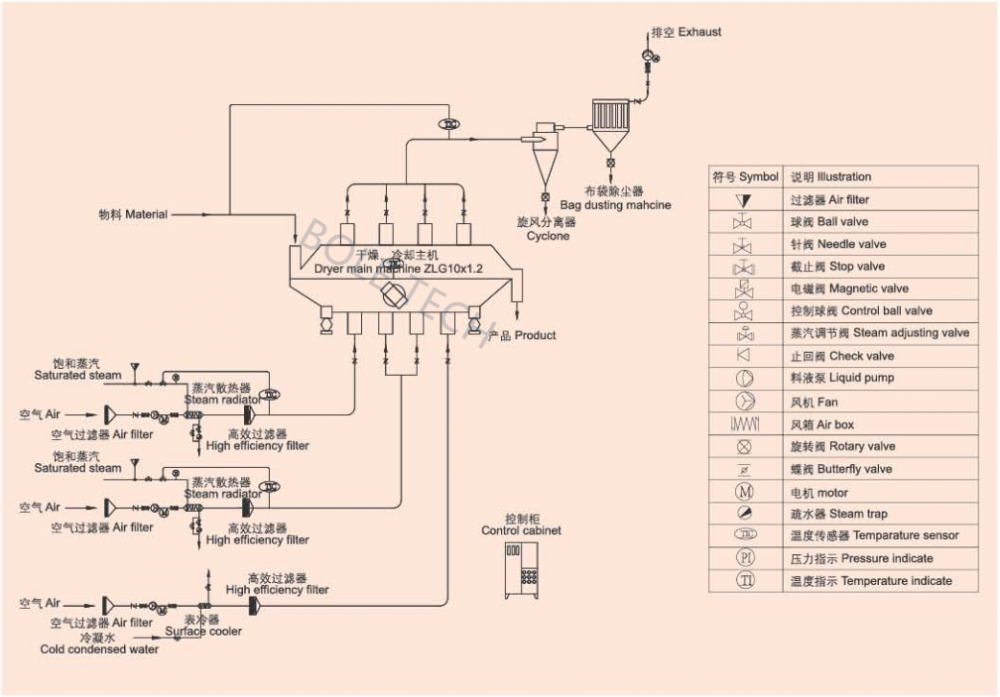

Bread crumbs vibration fluidized bed dryer machine

Options:

- ZLG

| Model No. : | ZLG |

|---|---|

| Brand Name : | Bole Tech |

| species : | Fluid Bed Drying Equipment |

Changzhou, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Product description

Description of vibration fluid bed dryer:

Bread crumbs Vibrating Fluid Bed Dryer adopts fully enclosed structure, which can effectively prevents cross pollution between materials and air, resulting in a clean working environment. The materials enter into the drying machine via feed inlet, under the effect of exciting force, the materials along the horizontal direction proceed forward continuous movement. Hot air from top to bottom or from bottom to top conducts heat transfer with the materials through fluidized bed, thus uniformly drying the materials. Hot air passes through the pore plate of fluidized bed to transfer the heat, and then expels from the air outlet and the dried materials are expelled from the discharge opening.

Features of vibration fluid bed dryer:

(1) Vibrating motor is used to achieve constant operation, smooth running, convenient maintenance, low noise and long using life.

(2) Uniform fluid-bed makes no dead gaps phenomenon and blowing through phenomenon. You can get uniform dry and cool products.

(3) Stepless adjustment. Thickness and moving speed of raw material inside the machine and the vibration amplitude can be adjusted freely.

(4) Less damage to the surface of raw materials. It can be used to dry material easy to be broken.

(5) The work efficiency is not affected even if the shape of granules is irregular.

(6) Use fully sealed structure to prevent from cross pollution of raw materials. The working environment is clean.

(7) High mechanical efficiency and thermal heating efficiency. 30~60% energy can be saved compared with ordinary drying equipment.

Application of vibration fluid bed dryer:

This machine is applicable for drying and cooling powdery and granular materials in chemical, pharmaceutical, food, grain, mineral and other industries. Such as: citric acid, edible salt, industrial salt, HPMC, chicken essence, WDG, monosodium glutamate, borax, ammonium sulfate, compound fertilizer, shredded radish, soybean meal, distillers grains, seeds, slag, sugar and so on.

Parameters of vibration fluid bed dryer:

|

Model

|

Drying area

(m2)

|

Inlet air

temperature (℃)

|

Outlet air temperature (℃)

|

Moisture evaporation (kg/h)

|

Vibrating motor (kW)

|

|

ZLG3×0.3

|

0.9

|

70~140

|

40~70

|

20~35

|

0.8×2

|

|

ZLG4.5×0.3

|

1.35

|

70~140

|

40~70

|

35~50

|

0.8×2

|

|

ZLG4.5×0.45

|

2.025

|

70~140

|

40~70

|

50~70

|

1.1×2

|

|

ZLG4.5×0.6

|

2.7

|

70~140

|

40~70

|

70~90

|

1.1×2

|

|

ZLG6×0.45

|

2.7

|

70~140

|

40~70

|

80~100

|

1.5×2

|

|

ZLG6×0.6

|

3.6

|

70~140

|

40~70

|

100~130

|

1.5×2

|

|

ZLG6×0.75

|

4.5

|

70~140

|

40~70

|

120~140

|

2.2×2

|

|

ZLG6×0.9

|

5.4

|

70~140

|

40~70

|

140~170

|

2.2×2

|

|

ZLG7.5×0.6

|

4.5

|

70~140

|

40~70

|

130~150

|

2.2×2

|

|

ZLG7.5×0.75

|

5.625

|

70~140

|

40~70

|

150~180

|

3×2

|

|

ZLG7.5×0.9

|

6.75

|

70~140

|

40~70

|

160~210

|

3×2

|

|

ZLG7.5×1.2

|

9

|

70~140

|

40~70

|

200~280

|

3×2

|

Video

Changzhou, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier