Video

1 / 1

BOLE 160 ton injection moulding machine

$103000.00

≥1 Set/Sets

| Model No. : | BL160EKH |

|---|---|

| Brand Name : | Bole Machinery |

| Type : | Preform Injection |

Ningbo, Zhejiang, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

Product description

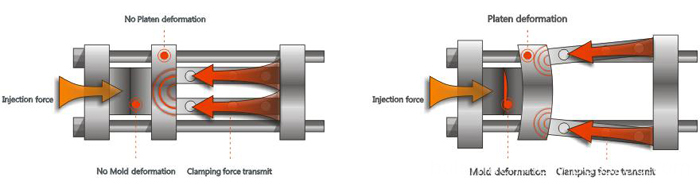

160 ton injection moulding machine

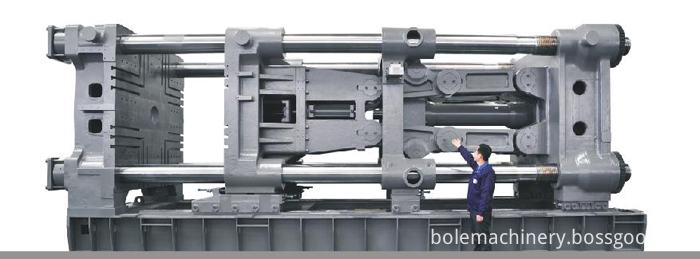

1. Bole Competitive Philosophy

Leading technology and performance

China unique producer, central locking toggle

CIML carbon-fiber products intelligent moulding line, made for lightweight of automobile

The performance of Electro- hydraulic hybrid two platen machine has reached the leading level

Big: Bigger one size than other brand machines.

Precision: Products higher precision.

Save: Help customer save 2- 5% material.

2. Product Instructions

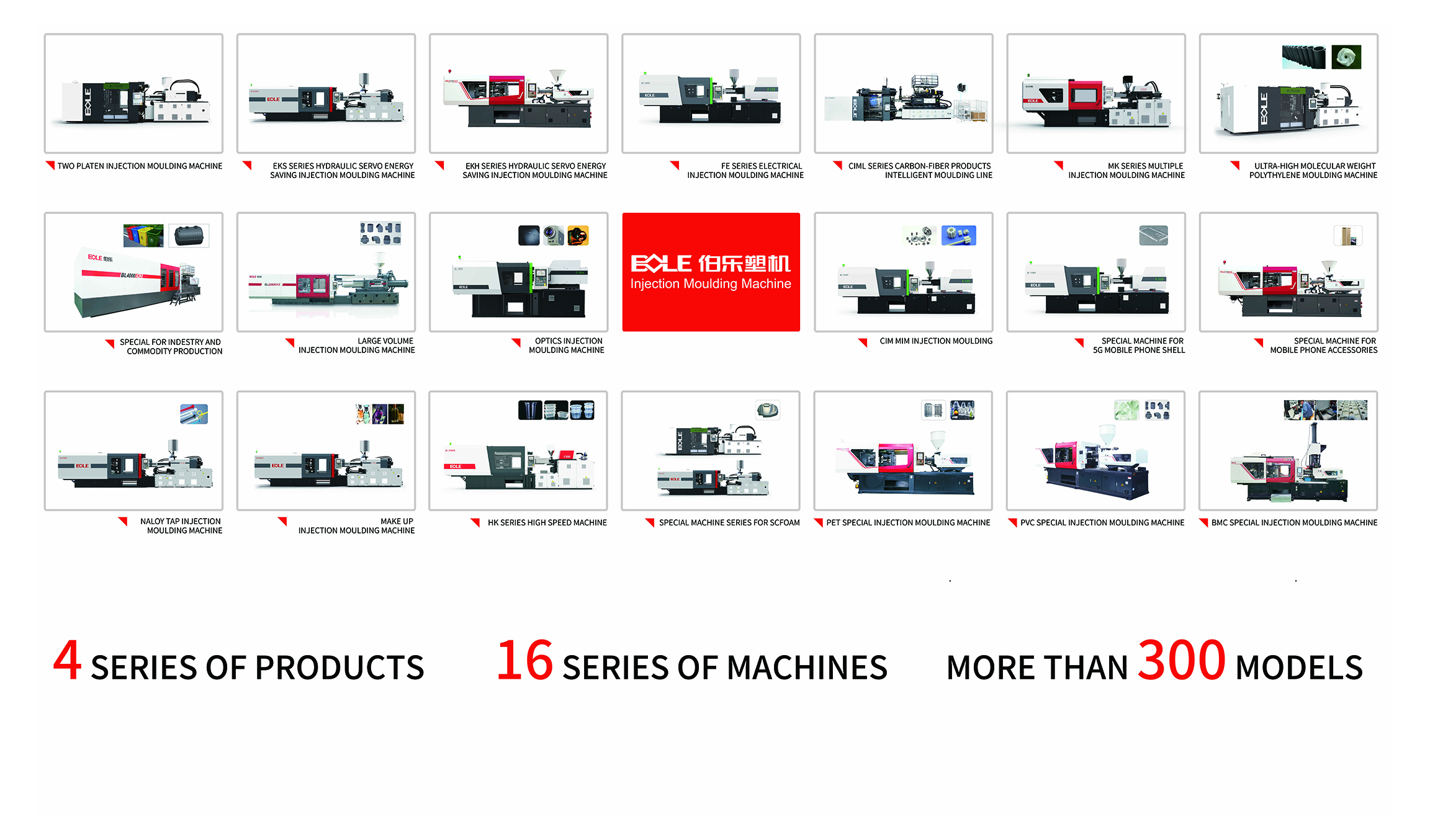

Bole central clamping toogle

■ 100% clamping force use, 10%-20% higher than traditional toggle structure.

■ Less possibility of flash, save flash trim work.

■ Save 2-5% material.

■ Offer good protection to mould, platens and tie bars.

■ Opening stroke 10-20% longer.

EKH series hydraulic servo energy saving injection moulding machine

EKW series hydraulic servo energy saving injection moulding machine

Traditional structure

■ With heavy clamping force waste, only 80-85% efficiency.

■ Moving platen with obvious deformation, cause flashes, waste of material and labor of trim the flashes.

| EKH系列技术参数表 | UNIT | BL160EKH/C490 | ||||

| 国际标准规格 | International specification | 490 | ||||

| 螺杆直径 | Screw diameter | 螺杆规格 | A | B | C | D |

| mm | 36 | 40 | 45 | 50 | ||

| 螺杆长径比 | Screw ratio | 23 | 23 | 21 | 18 | |

| 理论注射容积 | Theoretical injection capacity | cm3 | 214 | 264 | 334 | 412 |

|

注射量 (以PS计) |

Shot weight(PS) | g | 197 | 243 | 307 | 379 |

| oz | 6.9 | 8.6 | 10.9 | 13.4 | ||

| 最大对空注射速率 | Injection rate into Air | cm^3/s | 127 | 156 | 198 | 244 |

| 最大对空注射速率 | g/S | 115 | 142 | 180 | 222 | |

| 注射压力 | Injection pressure | MPa | 230 | 186 | 147 | 119 |

| 理论塑化速度 | g/S (PS) | 16 | 21 | 29 | 38 | |

| 注射行程 | Injection stroke | mm | 210 | |||

| 最大注射速度 | Max. injection speed | mm/s | 125 | |||

| 最大螺杆转速 | Screw speed | r/min | 240 | |||

| 系统压力 | Sys. Pressure | MPa | 17.5 | |||

| 电机总功率 | Pump Motor(Min~Max) | kW | 13.4~18.7 | |||

| 电机数量 | number of Motors | PCS | 1 | |||

| 预塑电机功率 (1850-4000吨标配) | 可选配 | |||||

| 电热功率 | Heater power | kW | 9.5 | |||

| 温控区数 | Number of temp. control zones | 3+1 | ||||

| 锁模力 | Clamping force | kN | 1600 | |||

| 开模行程 | Opening stroke | mm | 420 | |||

| 拉杆内间距 | Space between tie bar | mm x mm | 455×405 | |||

| 最小模具厚度(T型槽) | Min. mould height | mm | 180(145) | |||

| 最大模具厚度(T型槽) | Max. mould height | mm | 500(500) | |||

| 最大模板距离(T型槽) | Max. distance Platen | mm | 920(920) | |||

| 顶出行程 | Ejector stroke | mm | 140 | |||

| 顶出力 | Ejector force forward | kN | 49 | |||

| 顶针回缩力 | Ejector force back | kN | 37 | |||

| 顶出杆数 | Number of ejector bar | PC | 5 | |||

| 干循环时间 | S | 2.4 | ||||

| 能耗(注1) | kW.h/kg | ≤0.4(1级) | ||||

| 料斗容积 | Hoper capacity | kg | 25 | |||

| 油箱容量 | Oil tank capacity | L | 180 | |||

| 机械外形尺寸(约) | Machine dimensions(L×W×H) | m x m x m | 4.9x1.4x2.1 | |||

| 机器重量(约) | Machine weight | Ton | 4 | |||

| 注1:能耗等级依照:GB/T30200-2013标准,依PP料测试; 注2:理论塑化能力为理论计算值 | ||||||

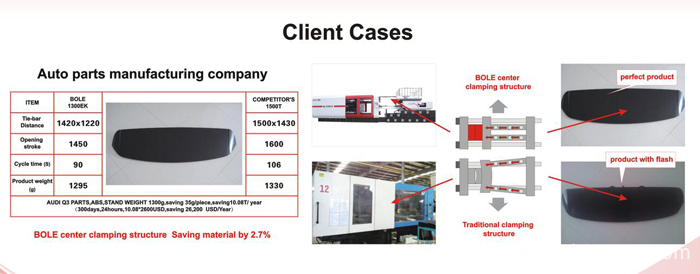

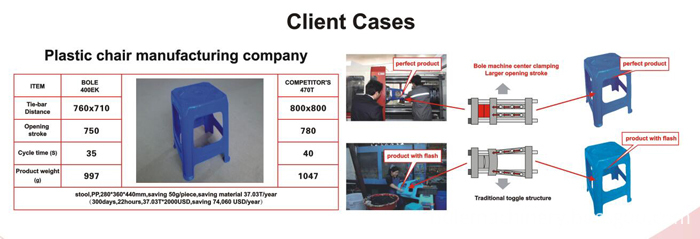

3. Clients Cases

4. About Bole Machinery

The sale of Bole Machinery is increasing steadily in recent years with the launch of new EKII series "China Unique Producer, Central Locking Toggle" machine. There are obvious advantages in the injection industry under the guidance of leading product technology strategy. With the design of central locking toggle structure of Bole Machinery, there are three main advantages compared with the competitors: a. High product accuracy; b. Less- flashes or no flash; c. 2% - 5% material- saving.

The world`s leading processing equipment

Video

Ningbo, Zhejiang, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier