1 / 1

blending tanks cosmetic cream high shear mixer homogenizer

$51000.00

≥1 Set/Sets

$48450.00

≥5 Set/Sets

Send Inquiry

| Mixer Type : | Homogenizer |

|---|

More

2yrs

Wenzhou, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Wenzhou Zoncic Machinery Technology Co.,Ltd

You might also like

Product description

Products Description

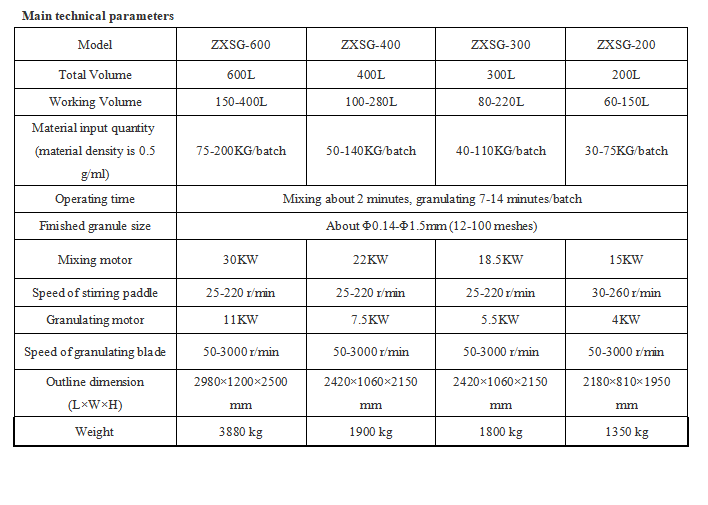

Product name | High-position wet mixing granulator | ||||||

Application | ZXSG Series Mixer and granulator is one of the standard process equipments in the solid dosage production procedure in pharmaceutical industry, and is also widely used in chemical, foodstuff industries, etc. This equipment has functions of mixing granulation and mill. | ||||||

Principle | Charge the materials by Pharmacy Lifter or vacuum charging system. Start the procedure, under the action of the impeller, materials are set in a multidimensional shear flow state and thoroughly mixed. Then, the spray gun system sprays the binder solution into the bowl to agglutinate with the materials and, under the combined action of the impeller and chopper, uniform and porous granules are produced. On finishing the granulation process, granules are discharged through the discharge port to the cone mill for homogenization of granules and de-agglomeration of agglomerate. Then milled granules are discharged to a Fluid-bed dryer for drying application. | ||||||

The whole process consists of two procedures: mixing and granulating. The adhesive is charged into the material pot from the conical hopper. Along with the filling of adhesive, the powder raw materials keep rotating in the pot under the action of stirring paddles once the hopper is closed. In the meanwhile, they grow up the shape of liquid bridge under continuous effects of conical wall. Under the action of extrusion, friction as well as kneading by paddles and conical pot wall, all materials gradually turn loose and soft. At last, open the material outlet and the wet granules will be pushed out under the centrifugal force of paddles. The soft materials are granulated via the granulating cutters but not the forced extrusion, which will be cut into tiny and uniform granules under the semi-fluid state, realizing the mutual transformation between two different materials. | |||||||

Application Examples | Mixing powder with powder (high precision and uniform) Granulating powder with adhesive (for dense granules) | ||||||

MOQ | 1set | ||||||

OEM | Accept customization | ||||||

Product Show

Company Profile

Manufacturing Technique

Certifications

FAQ

1 .Q Do you accept a customized order?

A: Yes ,we do ; We could manufacture all kinds of required equipments according to your technical drawings;

2.Q: Can you make a design for us?

A:Yes, we could making a production line according to customer’s requirements. We could do the key project.

3.Q:Can your engineer come to our place for installation guides?

A:Yes, we could. We will provide a video and document for installation;If you still have problems we will send our engineer oversea for installation guide;

4.Q:When is the lead time?

A: In 50 days after receiving the deposit.

For your inquiries, pls kindly let us know:

1. What is your products? Cream,toothpast, moisturizer,night cream, vanishing cream,suncream etc.

2.What is the capacity do you want for this vacuum emulsifying machine? 100L,200L300L,500L,1000L, etc.

3. Required heating method: electric heating or steam heating?

4. Required voltage and frequency of power supply? eg:380V 50Hz 3phase?

5. Requirement of Certificate

Contact Us

2yrs

Wenzhou, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier

Send Inquiry