Video

1 / 1

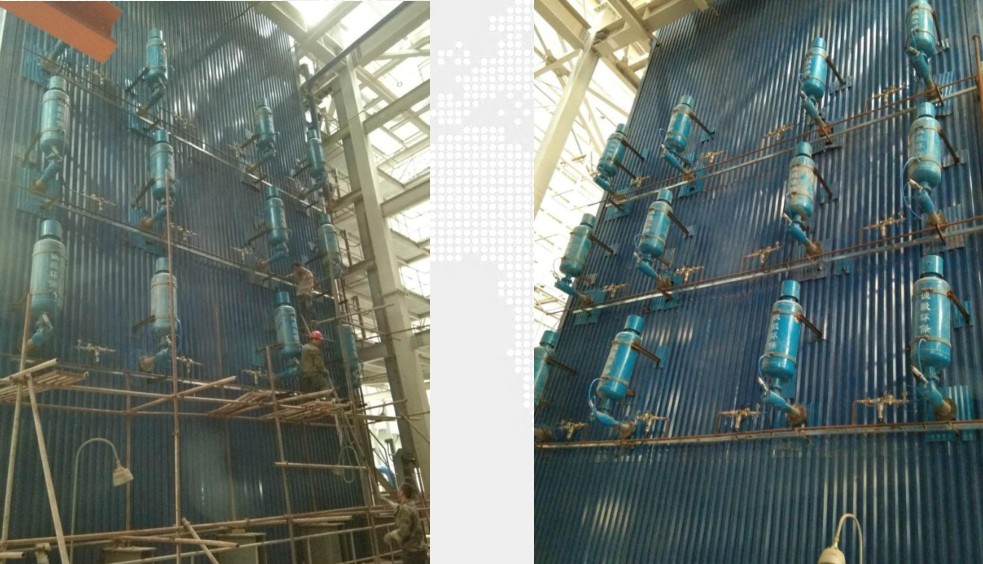

Biomass Boiler Shock Wave Cleaning System

$7000.00

≥1200 Piece/Pieces

| Brand Name : | Jinan Yuanda Power Equipment |

|---|---|

| status : | New |

Jinan, Shandong, China

- Manufacturer

- Retailer

- Service

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

Explosion Sootblower SPG Shock Pulse Generators Gas Explosion Garbage Incinerator Air Shock Wave Sootblower Biomass Boiler Shock Wave Cleaning System Advantages:

No gas consumption, absolutely no flashback, absolutely no squib, which essentially realizes equipment safety;

Only compressed air / nitrogen is consumed, and only 7 cents are needed for each shock wave operation, with extremely low cost;

After each shock wave is released, the nozzle rotates by 30 ° to realize 360 degree soot blowing without dead angle. Traditional gas

More than 3 times the range of shock wave soot blowing;

The pneumatic shock wave soot blowing intensity is large, the soot blowing intensity is adjustable, safe and reliable, and there is no damage;

It is especially suitable for the severe ash deposition conditions after low nitrogen combustion / SNCR / SCR;

Successfully solved the problem of ash accumulation at difficult parts such as the flame angle, horizontal flue and mixing chamber;

Used for floating ash, viscous ash, coking ash, sintering ash and other different working conditions;

Wide application range, successfully applied to coal fired boilers, CFB boilers, garbage boilers, biomass boilers

Different ash deposition conditions such as waste heat boiler in various industries.

Reliable, convenient maintenance and flexible control.

Widely used in following industries:

Pharmaceutical Industries

Steel Industries

Paper & Pulp Industries

Chemical Industries

Petrochemicals Industries

Textile Industries

Sugar Mills

Processing Units

Soot Blower Types

Air Shock Wave Soot Blower

Sonic Sootblower

Long retractable soot blower

Lance tube soot blower

Rotary soot blower

Steam soot blower,etc.

Brand:Jinan Yuanda Power Equipment

Related power plant boiler parts and power plant machine you may need:

|

Boiler Pressure Parts |

Boiler Casting Parts |

Boiler Auxiliary Equipment |

|

Boiler economizer |

Boiler Air Nozzle |

Boiler Coal Feeder |

|

Boiler Superheater |

Boiler Grate |

Boiler Slag Remover |

|

Boiler Air Preheater |

Boiler Erosion Tube Shields |

Boiler Ash Conveyor |

|

Boiler Water Wall |

Boiler Cyclone Separator |

Coal Crusher |

|

Boiler Drum |

Boiler Bend |

Boiler Fan |

|

Boiler Header |

Boiler Door |

Biomass Dryer |

|

Boiler Fin Tube |

Boiler Expansion Joint |

Steam Turbine Parts |

|

Power Plant Spare Parts |

Elbow Pipe Fittings |

Boiler/Furnace Repair Service |

|

seamless steel tubes/pipes; ERW steel pipes |

Other Steam Boiler Casting |

Boiler Service |

Sootblower in Boiler Application:

1.Boiler Economizer,Boiler Superheater, Tubular Air Preheater,Rotary Regenerative Air Heater of Utility Power (Power Station Boiler Pulverized Coal Fired Boiler, Cfb Boiler,Chain-Grate Boiler );

2.Slag Tube,Convection Air Preheater, Boiler Super Heater, Boiler Economiserof Hrsg Waste Heat Recovery Boiler(Exhaust Heat Boiler) of Ferrous/Black Metal Smelting Industry,Nonferrous Metals Smelting Industry,Oil Refining Industry,Coal Petroleum Chemical Industry,Cement Building Materials Industry.

3.Membrane Water Cooled Wall, Evaporator, Tube Bundle,Generating Tube Bank, Boiler Conversion Tube Bank, Boiler Superheater, Economizer, Boiler Air Heater Of Environmental Protection Boiler (Municipal Solid Waste Incinerator, Municipal Medical Waste Incinerator, Biomass Incinerator,Cfb/Cfbb/Cfbc Circulating Fluidized Bed Boiler And Other Waste Combustion Furnace;

4.Conversion Section, Boiler Economizer Coils, Superheater Coils,Boiler Air Heater Of Oil Burning Boiler/ Oil Fired Boiler/Gas Fired Boiler in Oil Refining Industry And Petrochemical Industry.

5.Tubular Heat Exchanger For In Heating And Cooling Section, Boiler Conversion Bank Of Tubes In Flue Gas Desulfurization Boiler.

6.Conversion Bank Tube Bundle, Economizer, Air Preheater, Etc Of Hot Water Boiler, Boiler Equipped With Heat Absorption Equipment In Other Boiler Furnace.

Sock Wave Soot Blower Successful Cases Above

Boiler Capacity Boiler Cleaning Service Sootblower Used For:20T/h,29T/h, 58T/h, 35T/h, 45T/h, 48T/h, 50T/h, 65T/h, 75T/h, 85T/h, 95T/h, 100T/h, 116T/h, 120T/h, 130T/h, 150T/h,168T/h, 170T/h, 190T/h, 220T/h,232T/h, 240T/h, 250T/h,260T/h, 280T/h, 300T/h, 320T/h, 400T/h,420T/h, 440T/h,450T/h, 480T/h, 490T/h,500T/h,550T/h, 600T/h, 650T/h, 670T/h, 690T/h,800T/h,850T/h, 1025T/h,

Boiler Burning Fuel:

Coal, Lignite,lean coal, lignite, subbituminous, bituminous,anthracite

biomass renewable energy fuel,Agriculture waste: Wood pellets,wheat straw, corn straw, cotton, peanut straw, rice straw, sugarcane leaves, rice husk, peanut shells, corn cob, baggage, palm fiber, palm shell, empty fruit bunch(EFB)

Forest waste: Wood piece, wood chip, sawdust, wood branch, bark, leaves, green mud etc.

Industrial waste: Cloth, paper, rubber, plastics, leather, sludge, medical waste etc.

Contact Person

Video

Jinan, Shandong, China

- Manufacturer

- Retailer

- Service

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier