Video

1 / 1

Automatic Carton Box small Corrugated Box Making Machine

| Model No. : | JX1625 |

|---|---|

| Applicable industry : | Food &Amp; Beverage Factory,Home Use,Printing Shops,Construction Works |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Personalized customization fully automatic carton box small corrugated box making machine

Overview:

Our production of automatic cutting machine is an intelligent fabric cutting, which device is successfully solved the traditional cutting (hand scissors, electric clippers) high-technology workers cutting costs, material waste, low productivity features .

Our main products include intelligent digital cutting machine and flexible material intelligent cutting machine,cloth and lether cutting machine,high-tech composite cutting machine.Aoyoo CNC knife cutting machine is widely used in clothing,car interior,cloth sofa,carpet mat, shoes,textile,advertising,pack-aging,metal and other industries.

Configuration:

Bed: using seamless welding processing technology

Table surface: the overall PVC milling surface processing flatness processing error within ±0.1mm

Rail: CSK rail

Knife head: high-frequency vibration knife Blade: imported cutting blade

Panel: With independent control panel, you can insert U disk to work offline

Transmission system: belt drive

Optional

Paintbrush: Mark the processing material, mark the processing serial number and the processed car model

Punching knife: Pre-punch holes according to the required industry use, reduce subsequent processing steps and improve production efficiency

Plotter: use the template to scan for subsequent finalizing processing

CCD camera positioning tool: industrial camera positioning is used to realize automatic machine vision positioning and cutting

Half-knife cutting tool: suitable for half-knife cutting of self-adhesive stickers

V-shaped groove cutting tool: The V-shaped cutting system can cut 4 kinds of V-shaped grooves at different angles, including 45°30°22.5°15°, etc.

Milling tool: suitable for cutting hard materials such as acrylic, composite wood, pvc, etc.

Technical Parameter:

Advantage:

1. Diversified head configuration

Freely combine standard handpieces according to different industry needs, and respond to production and processing requirements

2. Ergonomic design

6mm square tube is welded at high temperature, and the frame structure of the whole machine is strengthened to make the equipment more stable and the design is more ergonomic.

3. Safety device

The safety device ensures maximum safety of the operator during high-speed movement, and the infrared automatic sensing device effectively avoids the loss of cutting materials.

4. Automatic typesetting system

The system can automatically and automatically generate an optimized marker screen on the computer according to the user-set width and the number of samples.

5. Scientific wiring system

The simple and scientific circuit system can effectively improve the stability of the circuit, ensure the upgrade of the later products more convenient, and also increase the expandability of the equipment.

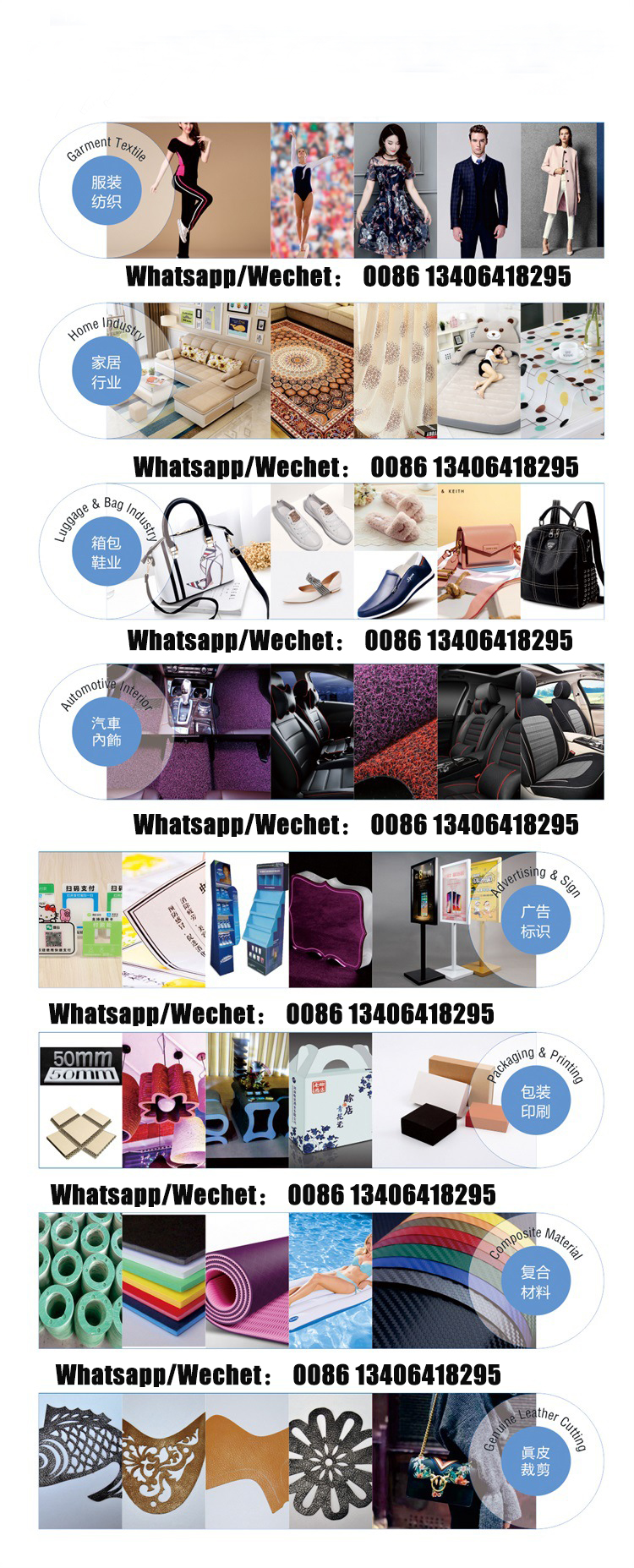

Applicable materials:

Leather, cardboard, plastic box, glass fiber, carbon fiber, paper honeycomb, corrugated cardboard, sticker, film, foam board, acrylic board, rubber, gasket material, garment cloth, footwear material, bags materials, non-woven fabrics, carpets, sponge, PU, EVA, XPE, PVC, PP, PE, PTFE, ETFE and composites.

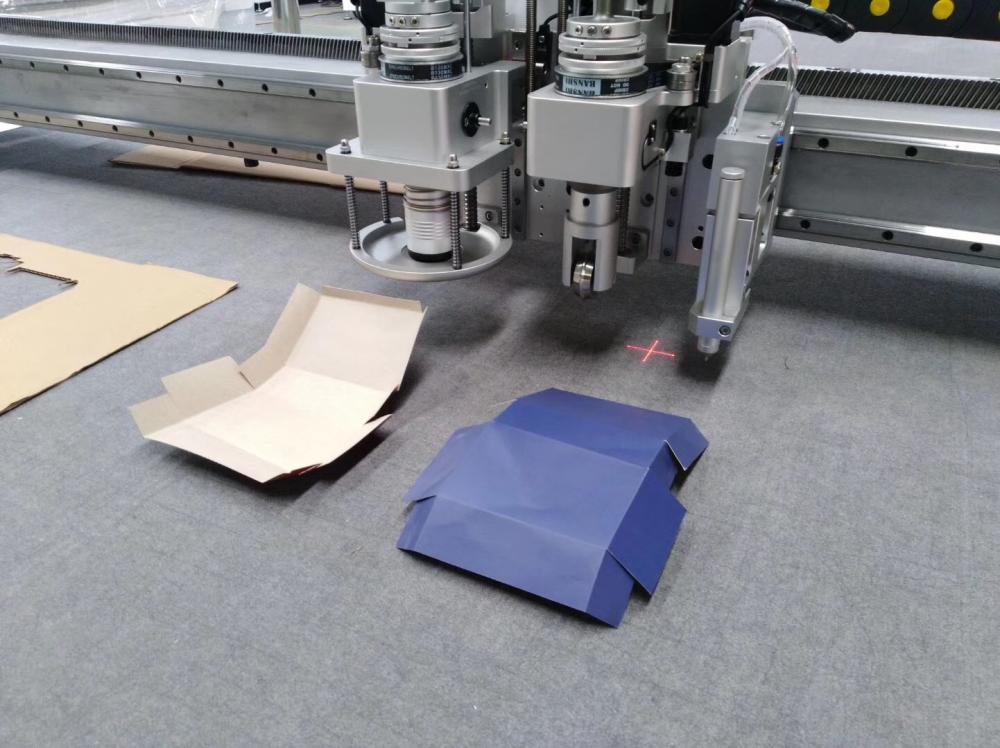

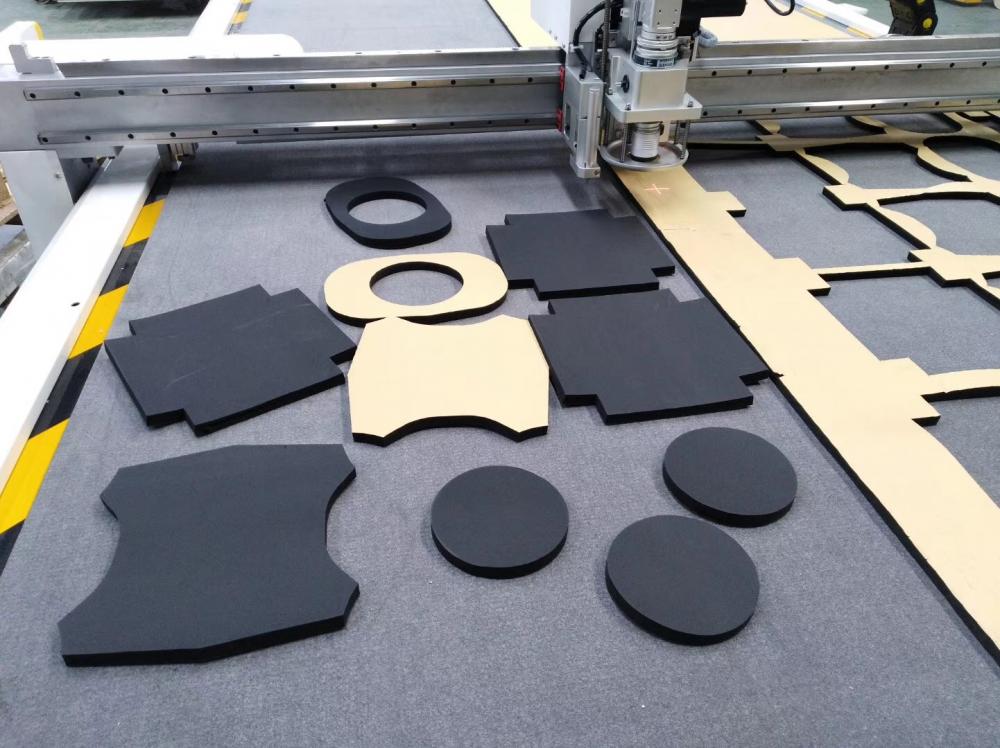

Detailed Images:

Applicable industry:

1. Home textile: Can provide customized cutting integrated solutions according to the home textile industry, which can not only significantly improve the utilization rate and processing efficiency of the fabrics in the home industry during the cutting process, but also effectively improve product quality and achieve high efficiency. Low consumables, high quality and comprehensive optimization

2. Textile and Apparel: Cutting system is designed for brand clothing, high-end custom clothing tailoring, and developed an automatic correction system to solve

3. Composite material: Cutting system replaces the hand-painted version of the composite product manufacturing process, manual cutting and other traditional processes, especially for complex samples such as heterogeneous irregular patterns, greatly improving production efficiency and cutting accuracy.

4. Automotive interior: System for different cutting requirements of the automotive interior industry, different cutting materials proposed a full-coverage cutting integrated solution, cutting products including fully enclosed foot pad, large surrounding foot pad, wire ring foot Pad, car seat cover and other flexible fabrics

5.Advertising packaging: System cutting provides a complete solution for the advertising industry, especially suitable for PP paper, KT board, Chevron board, self-adhesive, corrugated paper, honeycomb paper and other materials processing, and can be equipped with high-speed milling cutter for acrylic Processing of hard paper materials

Shipping:

Company Site:

FAQ:

Q:Are you factory or trading company?

A:We are factory and we have Import and export rights, There are many clients coming here to visit our factory every year , you are welcomed to come to our factory at any time knife fabric cutting machine

Q: How to judge if this cutting machine is suitable for me or not? cutting fabric machine

A: First, you should share something on the material (L*W*H,breathable or not) to be processed and other specific requirements, such as additional drawing function, punching holes function,etc. We will make first round judgement based on our experience. If necessary, we will make demo cutting for you, then we will share the video with you and discuss the possible solution.

Q: This is the first time I use this kind of machine, is it easy to operate?

A:We will send you manual and guide video in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can talk by phone, email or other contact ways.

Q:What is the warranty and quality of this machine?

A:Warranty normally 1-3 years, consumable except. during warranty period any accessories or parts damaged will replce by us for free. We are machine manufacturer in china more than 10 years,Our machine are senior engineers and designers developed, we consider any one aspect when using, so rarely appear quality problem, this is why we can gurantee customers warranty 1 years.

Q:What is the Price and payment terms?

A:EXW,CIF,FOB we all can accept payment:TT/Paypay/LC/Western Union.etc

Q:Delivery time

A:some small machine will delivery within 1 day, big machine will deliver within 3-5 days

Q: Where is your factory located? How can I get there?

A: Our factory is based in jinan, shandong province,China. You can fly to beijing, jinan or qingdao. We can pick you up at the air station or train station.

Q: Is there any after sales service?

A: We have integrated after sales service. Besides our own experienced engineers, we also offer local after sales service through the help of our agents. All this will make you convenient.

Video

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier