1 / 5

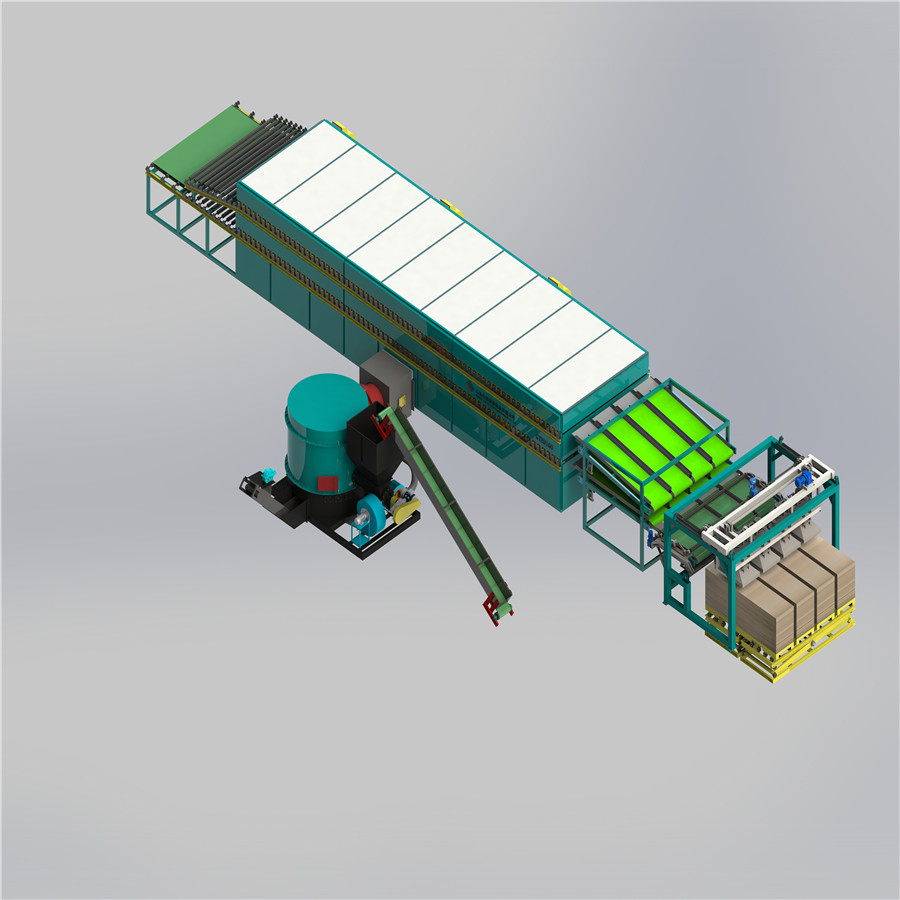

Automatic Biomass Veneer Drying Machine

| Brand Name : | Shine |

|---|---|

| Certification : | ISO |

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Online Expo

Product description

Product Description

Shine veneer dryer has low power consumption and small floor space,which can be used in small and medium plywood factory to dry the core veneer. This veneer drying machine allows automatic and programmable control system,which can save manual operation cost greatly.Equipped with biomass burner, this biomass veneer dryer machine can ensure perfect drying effect and reduce drying cost mostly.All kinds of waste wood such as waste bark,waste veneer can be burned as fuel directly,even the waste wood is wet.The temperature inside our wood veneer dryer is enough to reduce mositure content.And the veneer after drying is flat and has uniform moisture content.It would be better if Shine veneer dryers machine can be used for plywood production line.

Advantages of Veneer Drying Machine

1.Shine veneer dryer has the features of high productivity, energy efficiency, lowest drying cost and perfect drying effect.

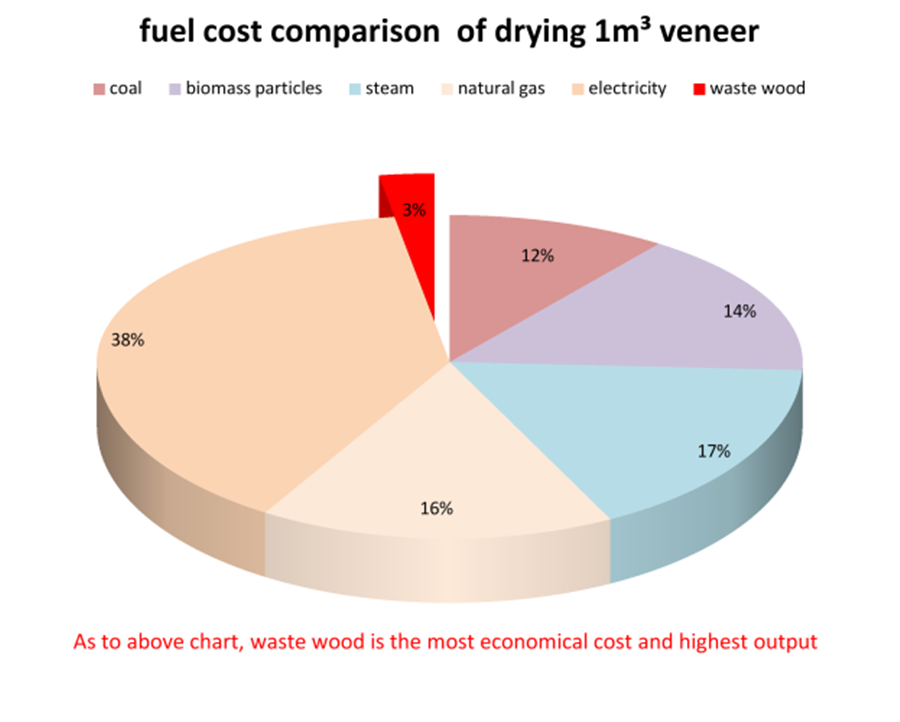

2.The biomass burner is the exclusive patent invented by Shine Machinery in China. It can burn all kinds of waste wood directly to reduce the fuel cost to the most. It has the advantages of high efficiency, low fuel consumption and energy saving. Compared to steam boiler or heat conduction oil boiler dryer, the drying cost of the biomass burner is the lowest. Both the steam type and the heat conduction oil type dryer need customers to provide heat sources and boilers, not only the steam boiler and heat conduction oil boiler cost are much higher than our biomass burner, but also the fuel cost of steam and heat conduction oil are much higher than waste wood.

3.The veneer after drying has uniform moisture content and it is flat without buckle or end waviness.

4.The veneer after drying is free of splits and the surface is in good condition for gluing.

5.Shrinkage and casehardening is kept to a minimum and collapse and honeycomb are avoided.

Our Company

Our Customers

Our Services

1.All kinds of mold can be made by customer's requirements

2.All price are based on FOB.QINGDAO,China

3.Payment;by T/T or L/C.

4.All the Parameters above just for reference,for they are updating all the time

5.Package:Standard packing

6.Warranty:All the machine enjoys one year's warranty,in this period

7.Any problems of machine,please feel free to contact us.We will try our best to make it.

Pre-sale services:

1) Provide the free consultation of all Core Veneer Dryer Machine

2) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

3) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Technical Parameters

|

Parameter Model

|

DHS20M

|

DHS24M |

DHS28M |

DHS32M |

DHS36M |

DHS40M |

|

Work width(m) |

3 |

3 |

3 |

3 |

3 |

3 |

|

Layer |

1 |

1 |

1 |

1 |

1 |

1 |

|

Veneer thickness(mm) |

0.5-5 |

0.5-5 |

0.5-5 |

0.5-5 |

0.5-5 |

0.5-5 |

|

Heating area (m)

|

16 |

20 |

24 |

28 |

32 |

36 |

|

Cooling area (m) |

4 |

4 |

4 |

4 |

4 |

4 |

|

Initial water content(%) |

50-80 |

50-80 |

50-80 |

50-80 |

50-80 |

50-80 |

|

Finished water content(%) |

10 |

10 |

10 |

10 |

10 |

10 |

|

Drying capacity (m³/h) |

0.5-0.65 |

0.65-0.8 |

0.8-1 |

1-1.2 |

1.15-1.35 |

1.3-1.5 |

|

Heat exhaustion(10000 kcal) |

17.5-23 |

23-285 |

28-35 |

35-42 |

40.25-47.25 |

45.5-52.5 |

|

Total power (kw) |

56 |

63.5 |

68 |

76.5 |

84 |

106 |

|

Overall size LxWxH(m) |

20*4.5*1.58 |

24*4.5*1.58 |

28*4.5*1.58 |

32*4.5*1.58 |

36*4.5*1.58 |

40*4.5*1.58 |

Our Certificate

Contacts us

We are the manufacturer of Core Veneer Dryer Machine from China . More details please contact us.

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

- Online Expo

Send your inquiry to this supplier