1 / 6

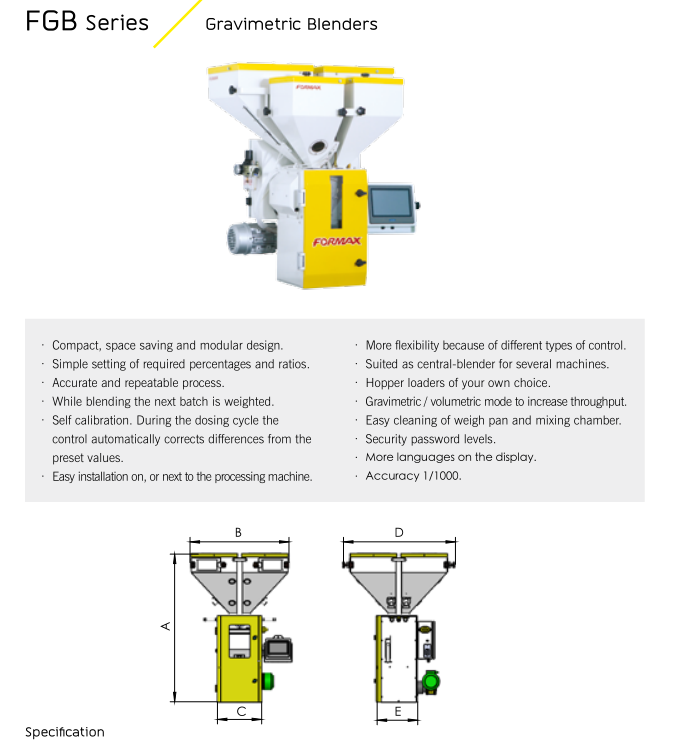

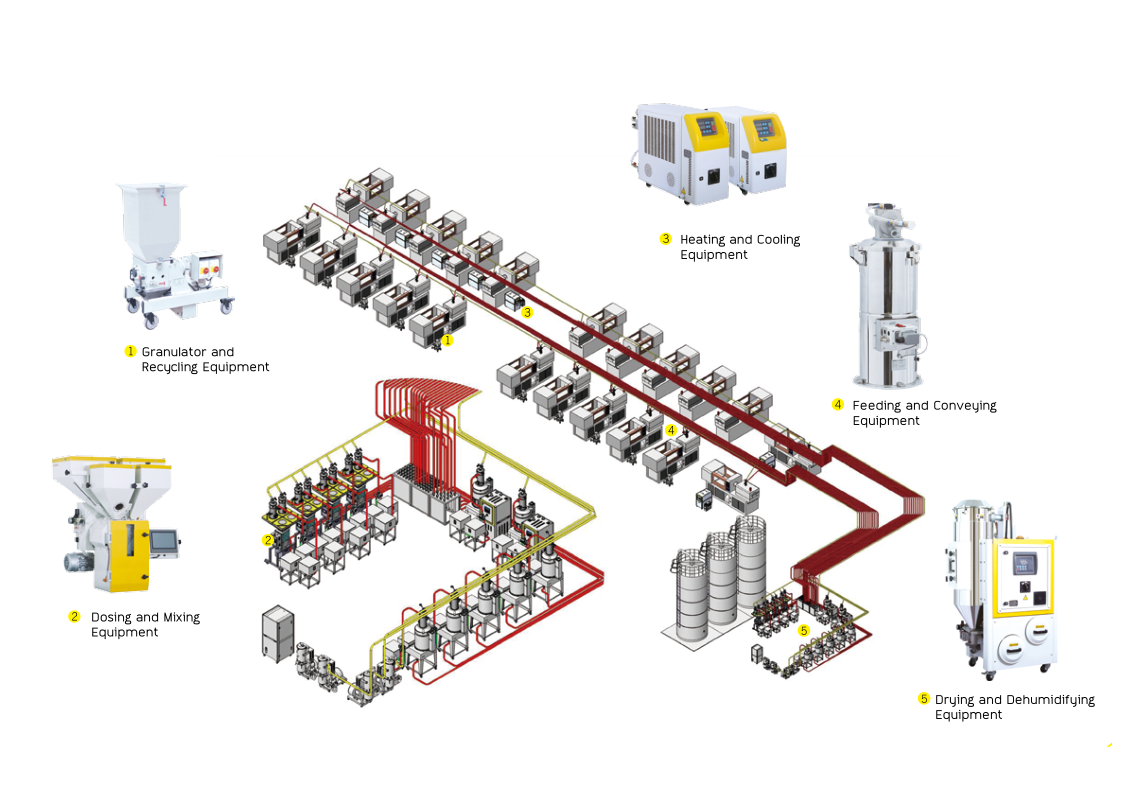

Automatic batching and mixing system equipment

| Brand Name : | Rainbow Wonder |

|---|---|

| status : | New |

Changzhou, Jiangsu, China

- Agent

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Product description

1. The automatic batching system controlled by the computer improves the precision of the batching and solves the problems of the complexity of manual batching, the loss of materials and the chemical hazards to the operator.

2. The high-efficiency pneumatic conveying system replaces the heavy labor of a large number of material handling processes and improves production efficiency.

3. The material handling process is completely carried out in a closed pipeline, which avoids dust pollution to the workshop environment and harm to workers.

4. The material preparation and processing process is more concentrated and efficient, and the output is higher, which can fully meet the needs of mass production.

5. Visual observation: The color of the good-quality mixture is normal, without impurities, and without agglomeration.

6. Bulk density measurement: the correct mixing process will increase the bulk density of the material.

7. Material fluidity: prepare a funnel and install a flapper valve at the discharge end. Load a certain amount of dry mixture sample into the funnel, open the flapper valve, and calculate the time it takes for the material in the funnel to completely drain. The shorter the time, the better the fluidity.

8. Flow performance test: good mixture has good fluidity.

9. Color inspection: Generally, colorimeters should be used to detect colors, and the inspection can be carried out under sunlight, ultraviolet light, fluorescence and white light. At the same time, test the sample and the standard product to determine whether the sample is qualified.

Changzhou, Jiangsu, China

- Agent

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier