1 / 3

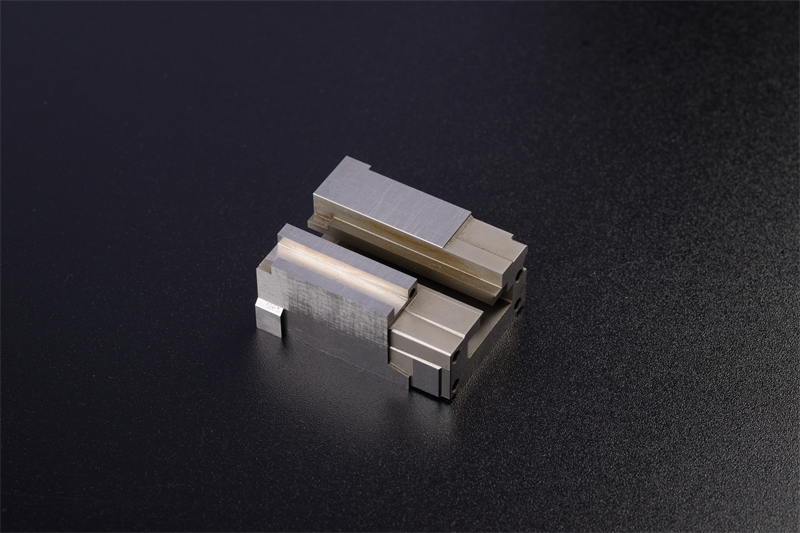

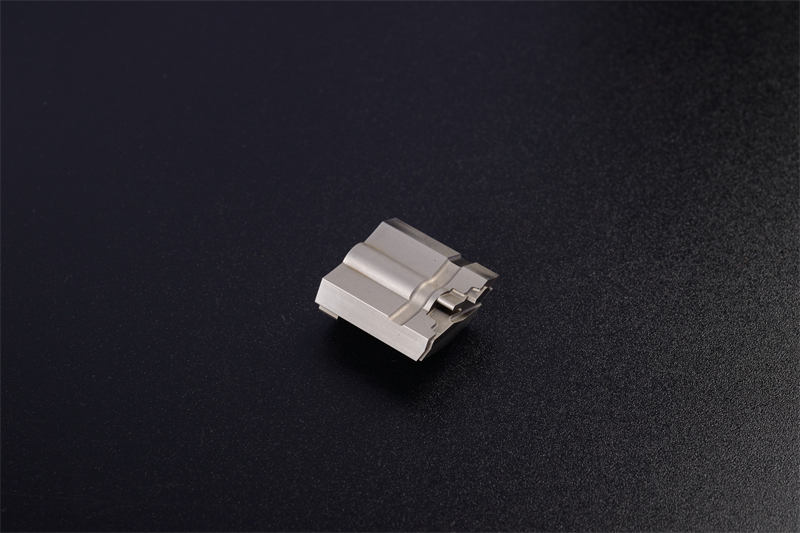

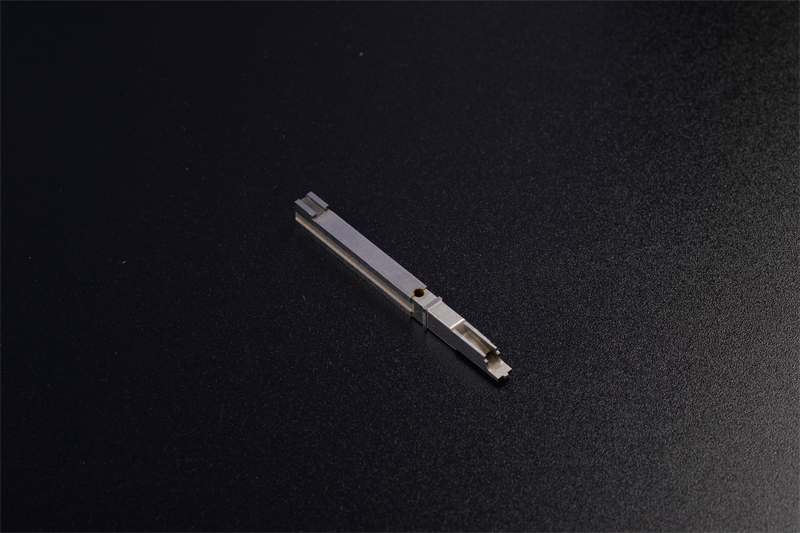

Auto Parts Plastic Mold Injection Molding

| Brand Name : | yushun |

|---|---|

| place of origin : | China |

Dongguan, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- Service

- Gold Supplier

- Platform Certification

Product description

To create an auto part using plastic mold injection molding, first, a CAD model of the part is created, which is then used to design a mold cavity. The mold is made from durable metals such as steel or aluminum and is designed to withstand high pressure and temperatures.

Auto parts plastic molds are specialized tools used in the manufacturing process of plastic auto parts. These molds are typically made from high-quality steel and precision-machined to produce highly accurate and consistent parts.

The process for creating auto parts plastic molds involves designing and engineering a 3D model of the part using computer-aided design (CAD) software. This model is then used to create a mold cavity that is the negative shape of the final part.

Once the mold is created, molten plastic is injected into the cavity at high pressure, filling it completely and taking on the shape of the mold. The plastic is then allowed to cool and harden before the mold is opened and the finished part is removed.

Dongguan, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- Service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier