1 / 6

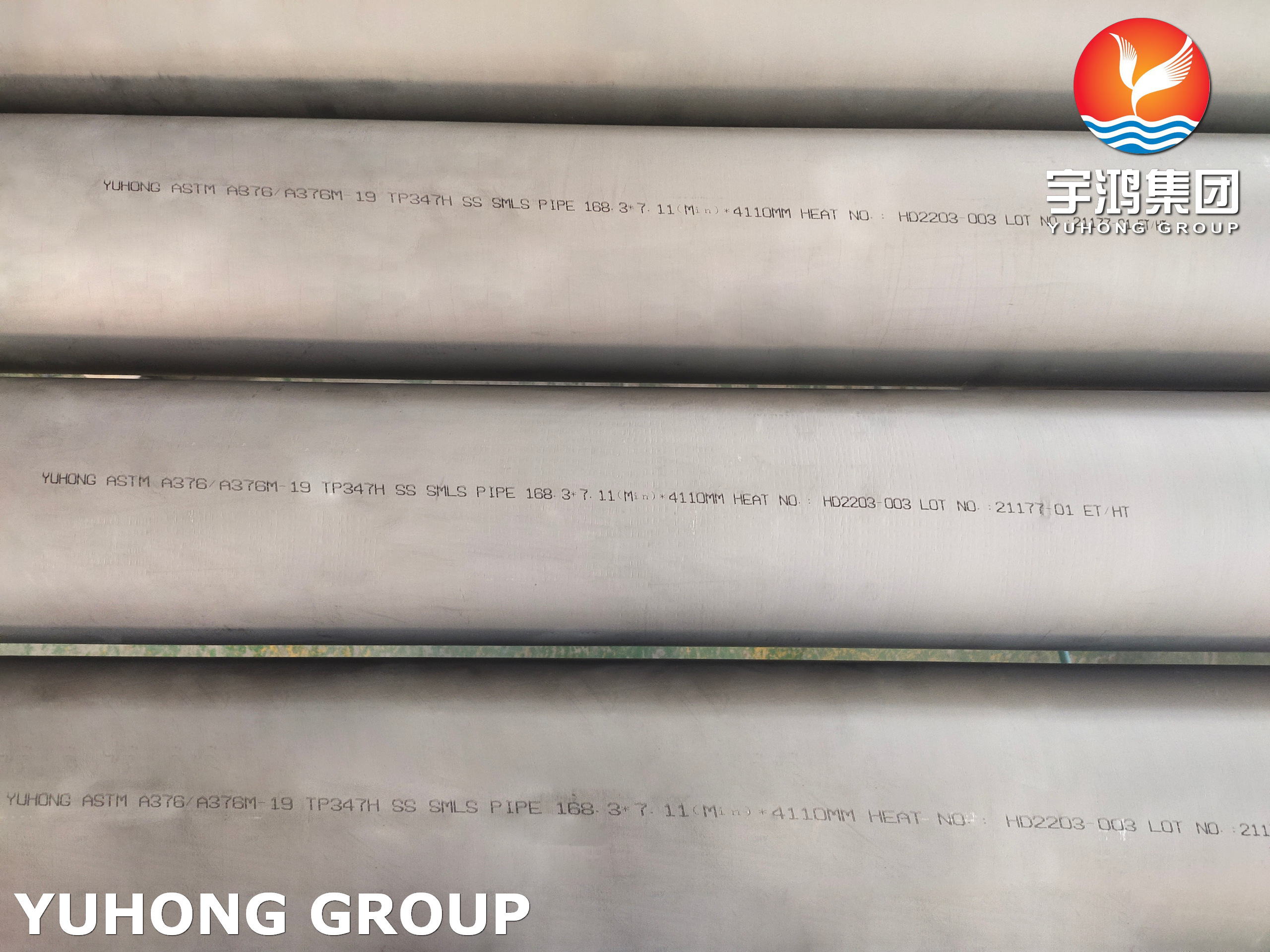

ASTM A376 Stainless Steel TP347H Seamless Pipe

| Model No. : | ASTM A376 TP347H |

|---|---|

| Brand Name : | YUHONG |

| standard : | Jis,Aisi,Astm,Din,En |

Product description

ASTM A376 Stainless Steel TP347H Seamless Pipe For High Temperature

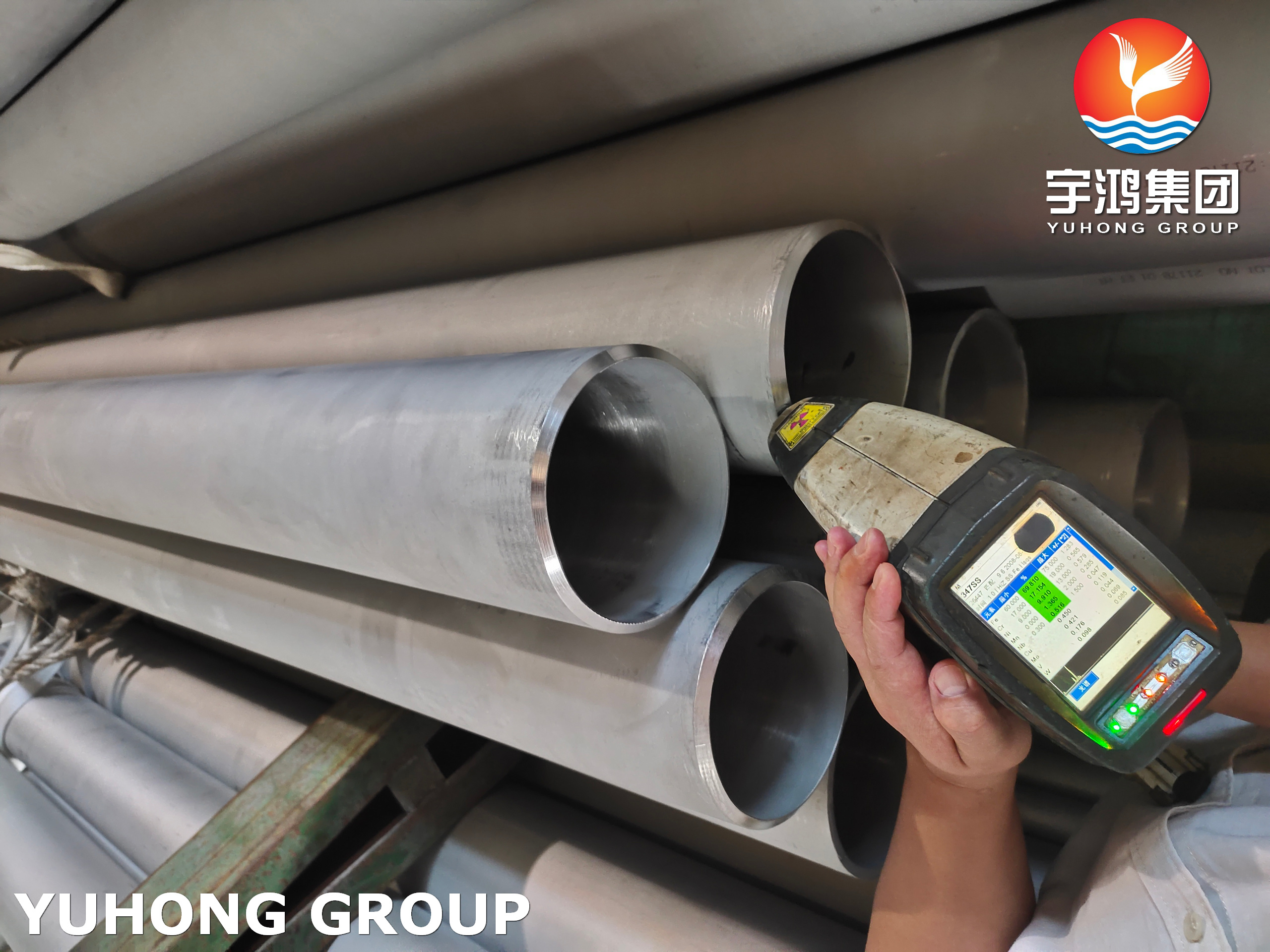

ASTM A376 Stainless Steel TP347H Seamless Pipe is a type of stainless steel pipe that is specifically designed for high-temperature applications. TP347H is a high carbon version of TP347 stainless steel, which provides enhanced strength and corrosion resistance.

The seamless construction of the pipe ensures a smooth interior surface, which reduces the risk of corrosion and allows for efficient fluid flow. This makes it suitable for use in various industries such as petrochemical, chemical processing, power generation, and oil and gas.

ASTM A376 specifies the requirements for seamless austenitic steel pipe intended for high-temperature and general corrosive service. The pipe is manufactured using a combination of hot working and cold finishing processes to achieve the desired dimensions and mechanical properties.

The TP347H grade of stainless steel offers excellent resistance to oxidation and high-temperature scaling, making it suitable for use in environments with temperatures up to 1000°C (1832°F). It also provides good resistance to pitting, crevice corrosion, and stress corrosion cracking.

The seamless pipe is available in various sizes and thicknesses to suit different application requirements. It can be further customized with different end connections such as plain ends, beveled ends, or threaded ends.

In conclusion, ASTM A376 Stainless Steel TP347H Seamless Pipe is a reliable and durable option for high-temperature applications. Its superior strength, corrosion resistance, and smooth interior surface make it ideal for use in demanding industries.

|

SS 347H |

|

|

Ni |

9 – 13 |

|

Cr |

17 – 19 |

|

C |

0.04 – 0.10 |

|

Mo |

3 – 4 |

|

Fe |

Balance |

|

Mn |

2 max |

|

Si |

0.75 max |

|

S |

0.03 max |

|

P |

0.045 max |

|

Co + Ta |

8xC min |

|

1.00 max |

|

Density |

8.0 g/cm3 |

|

Melting Point |

1454 °C (2650 °F) |

|

Tensile Strength |

Psi – 75000 , MPa – 515 |

|

Yield Strength (0.2%Offset) |

Psi – 30000 , MPa – 205 |

|

Elongation |

35% |

The production process of seamless pipes involves several steps:

1. Billet preparation: The process starts with the preparation of a solid cylindrical steel billet. The billet is heated to a high temperature to make it more malleable and easier to work with.

2. Piercing: The heated billet is then pierced with a mandrel to create a hollow shell. The mandrel helps to maintain the inner diameter of the pipe during the subsequent processes.

3. Rolling: The pierced billet is then rolled to reduce its diameter and increase its length. This process is known as elongation or reducing rolling.

4. Sizing: The elongated pipe is then passed through a series of sizing rolls to achieve the desired outer diameter and wall thickness. This process is called sizing or stretch reducing.

5. Heat treatment: The sized pipe is subjected to heat treatment to improve its mechanical properties. This involves heating the pipe to a specific temperature and then cooling it rapidly to achieve the desired hardness and strength.

6. Straightening: The heat-treated pipe is straightened using a straightening machine to remove any bends or deformations. This ensures that the pipe has a uniform shape and size.

7. Cutting: The straightened pipe is cut into desired lengths using a cutting machine. The cut ends are then beveled to facilitate welding or joining.

8. Inspection: The finished pipes are inspected for quality and compliance with specifications. This includes checking for dimensional accuracy, surface defects, and mechanical properties.

9. Surface treatment: Depending on the application, the pipes may undergo additional surface treatment processes such as coating, painting, or galvanizing to enhance their corrosion resistance.

10. Final inspection and packaging: The pipes undergo a final inspection to ensure that they meet all quality requirements. They are then carefully packaged and prepared for shipment to the customers.

Send your inquiry to this supplier