1 / 4

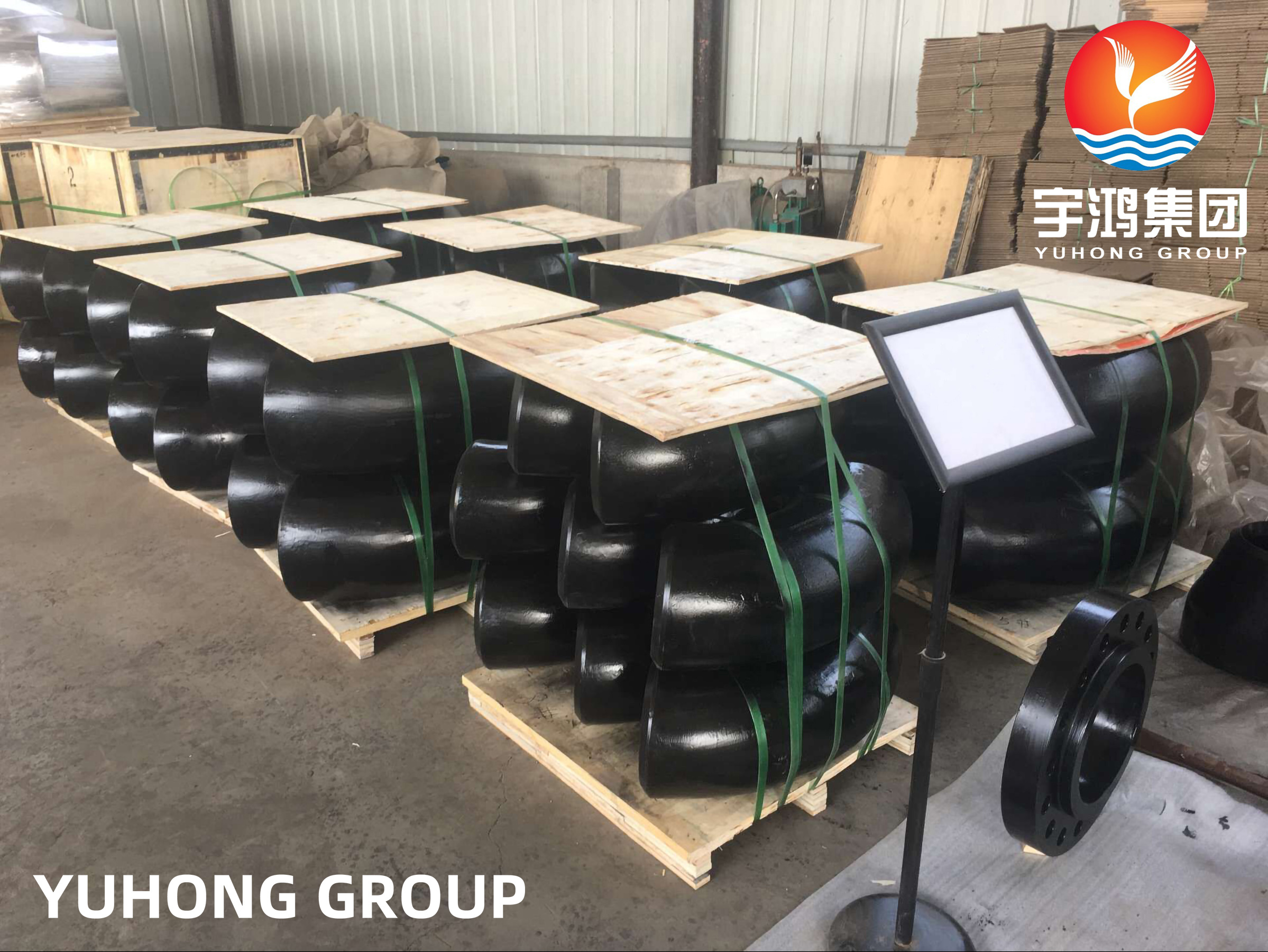

ASTM A234 WP22 Carbon Steel Butt Weld Fittings

Types:

- Elbow

- Tee

- Cross

Material:

- Carbon Steel

| Model No. : | A234 WP22 |

|---|---|

| Brand Name : | YuHong Group |

| place of origin : | China |

Product description

ASTM A234 WP22 Carbon Steel Butt Weld Fittings Elbow/ Equal Tee

What is ASTM A234 WP22?

ASTM A234 WP22 is a specification for pipe fittings made from low-alloy steel. It covers both seamless and welded fittings that are used in pressure piping systems at high temperatures. The WP22 designation specifically refers to the grade of the steel, which in this case is a low-alloy steel with added chromium and molybdenum for improved strength and corrosion resistance. These fittings are commonly used in industries such as power generation, chemical processing, and petroleum refining.

What is ASTM A234's scope?

ASTM A234 is a standard specification for pipe fittings of wrought carbon steel and alloy steel for moderate and high-temperature service. Its scope covers the requirements for butt-welded fittings made from seamless or welded pipes, with specific grades and classes designated for various applications.

The standard covers fittings of various types, including elbows, tees, reducers, caps, bends, and other types of fittings that are used in piping systems. These fittings are intended for use in pressure piping systems at moderate and elevated temperatures.

ASTM A234 specifies the materials, dimensions, tolerances, mechanical properties, heat treatment requirements, and testing criteria for these fittings. It ensures the quality and consistency of pipe fittings used in various industries such as oil and gas, power generation, chemical processing, and more.

Chemical Composition of Grade WP22 Alloy Steel Butt Weld Fittings

|

Grade |

C |

Mn |

Si |

S |

P |

Cr |

Mo |

|

A234 WP22 |

0.05-0.15 |

0.3-0.6 |

≤0.5 |

≤0.04 |

≤0.04 |

2-2.5 |

0.87-1.13 |

Mechanical Properties of ASTM A234 Alloy Steel WP22 Butt Weld Pipe Fittings

|

Grade |

Tensile Strength (Mpa) |

Yield Strength (Mpa) |

Elongation % |

|

A234 WP22 |

415-585 |

≥205 |

≥20 |

What is ASTM A234 WP22 Elbow?

ASTM A234 WP22 elbow is a type of pipe fitting that is specifically designed to change the direction of flow in a piping system. It is made from ASTM A234 WP22, which is a low-alloy steel with added chromium and molybdenum, known for its high strength and corrosion resistance.

The ASTM A234 WP22 elbow is available in various degrees of curvature, such as 45 degrees, 90 degrees, or 180 degrees. The degree of curvature determines the angle at which the elbow will change the direction of the pipe.

These elbows are butt-welded fittings, meaning they are connected to the pipe by welding. They have a beveled end that is prepared for welding, and they are joined to the adjacent pipe or fitting using a welding technique such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding.

ASTM A234 WP22 elbows are commonly used in high-temperature and high-pressure applications, such as in power generation, oil and gas refineries, chemical processing plants, and other industries where a change in direction is required in the piping system. They provide a strong and reliable connection while maintaining the structural integrity of the piping system.

ASTM A234 WP22 fittings offer several advantages due to their specific composition and properties:

1. High strength: ASTM A234 WP22 fittings are made from low-alloy steel with added chromium and molybdenum, which enhances their strength and toughness. This makes them suitable for high-pressure and high-temperature applications.

2. Corrosion resistance: The addition of chromium and molybdenum in the alloy composition improves the resistance to corrosion, especially in environments that contain corrosive elements such as acids, alkalis, and chlorides.

3. Excellent weldability: ASTM A234 WP22 fittings have good weldability, allowing for easy and efficient joining to the piping system. This ensures a reliable and leak-free connection.

4. Versatility: These fittings can be used in various industries and applications, including oil and gas, power generation, chemical processing, and more. Their versatility makes them suitable for a wide range of piping systems.

5. Cost-effective: Comparatively, ASTM A234 WP22 fittings provide a cost-effective solution due to their long-term durability, resistance to corrosion, and high-performance characteristics. This can result in reduced maintenance and replacement costs over the lifespan of the fittings.

Overall, the advantage of ASTM A234 WP22 fittings lies in their combination of high strength, corrosion resistance, weldability, versatility, and cost-effectiveness, making them a reliable choice for demanding applications.

ASTM A234 WP22 Alloy Pipe Fittings Applications:

-Oil and Gas Pipeline

-Chemical Industry

-Plumbing

-Heating

-Water Supply Systems

-Power Plant

-Paper & Pulp Industry

-General Purpose Applications

-Fabrication Industry

-Food Processing Industry

-Structural Pipe

Send your inquiry to this supplier