1 / 2

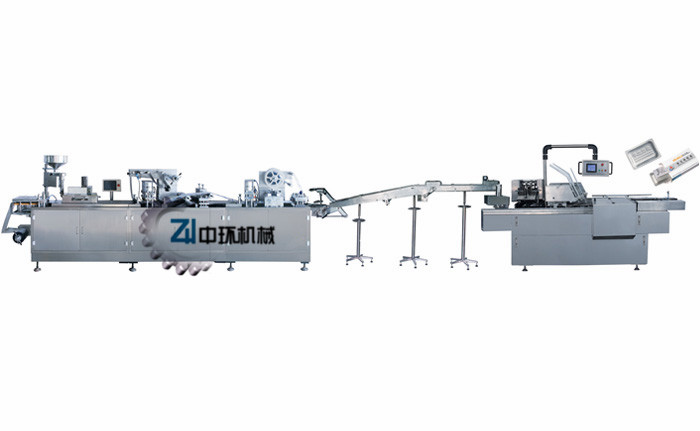

AL/PL/AL Blister(Tropical Blister)Packing Cartoning Production Line

| Model No. : | DZL-250F |

|---|---|

| Brand Name : | zhonghuan |

Product description

Applications:

Introducing internal and external advanced technology,our factory researched,designed and manufactured the machine which is the most optimized environmental protection packer. The machine is assembled with three parts,and can be packed and transported separately. Integrating mechanise,electricity and gas,it completes separately all procedures including warm-up,blister forming,automatic feeding,heat sealing and synchronous adjustment of Aluminum-Plastic strip,empty-detecting,hard Aluminum forming,second heat sealing,batch number printing,blanking and scrap-collecting,etc.under control of PLC. The machine suitable for blister packing with Aluminum-Plastic,Aluminum-Aluminum and Aluminum-Plastic-Aluminum.

1. Travel scope can e adjusted,mould is located by located groove so that it's easy to change mould. Adopt the moulds of pressing-and-frothing and cool-forming.

2. The material is fed automatically. The mould and feeding equipment can be designed as user's requirements.

3. Speed is shifted by stepless transducer.Adopt the interface of human-machine and PLC programmable controller.

4. Adopt photoelectric empty-detecting equipment and waster-eliminating equipment.

5. Double stepping motor drive wheel to grip and tow wrapper,synchronizing accurately.

6. The heating moulds separate automatically when the machine stops,which contributes to protect the material between them and extend the machine's life.

Main technical data:

Capacity(box/min) 80-110/min

Packing material Box dimension(mm)(L×H×W ) (65-125)×(40-78)×(12-65)

Cardboard of box required(g/㎡) 250-350g/㎡

Leaflet dimension)(L×W) (800-300)×(70-210)

Leaflet paper required(g/㎡) 55-65g/㎡

Clean compressed air (pressure) 0.6-0.8MPa

Air consumption (m3/min) ≥0.3

Power AC380V 50HZ 1KW AC380V 50Hz 1KW

Overall dimension 3100×1380×1800

Weight 1700

Model 320F 250F 160F

Blanking frequency(times/min) 15-30 15-30 15-30

Sheet's quantity of one blanking(sheets) 3-4 5-6 2

Adjustable scope of feed travel(mm) 3600-7200 4700-10800 1800-3600

Appropriate for Capsule 10-160 10-170 10-150

Max Forming area and depth(mm) PVC(For medicine) 250×160×25 320×170×25 160×150×25

Tropicalized Aluminum 250×160×15 320×170×15 160×150×15

Capacity of air compressor((m3/min) ) ≥0.38 ≥0.45 ≥0.36

Power supply 380V 50HZ 10KW 380V 50HZ 12KW 380V 50Hz 9KW

Wrapper specification(mm) PVC for medicine 250×(0.15-0.5) 320×(0.15-0.5) 160×(0.15-0.5)

Aluminum foil 250×(0.02-0.035) 320×(0.02-0.035) 160×(0.02-0.035)

Tropicalized Aluminum 250×(0.09-0.15) 320×(0.09-0.15) 160×(0.09-0.15)

Overall dimensions(mm) 4300×635×1400 4800×718×1500 3800×680×1400

Part size(mm) 1600×635×1400 1600×718×1500 2530×680×1400

1600×635×1400 1600×718×1500 1270×680×1400

1100×635×1400 1600×718×1500

Weight(Kg) 2400 2000 1200

Model 320F 250F 160F

Blanking frequency(times/min) 15-30 15-30 15-30

Sheet's quantity of one blanking(sheets) 3-4 5-6 2

Adjustable scope of feed travel(mm) 3600-7200 4700-10800 1800-3600

Appropriate for Capsule 10-160 10-170 10-150

Max Forming area and depth(mm) PVC(For medicine) 250×160×25 320×170×25 160×150×25

Tropicalized Aluminum 250×160×15 320×170×15 160×150×15

Capacity of air compressor((m3/min) ) ≥0.38 ≥0.45 ≥0.36

Power supply 380V 50HZ 10KW 380V 50HZ 12KW 380V 50Hz 9KW

Wrapper specification(mm) PVC for medicine 250×(0.15-0.5) 320×(0.15-0.5) 160×(0.15-0.5)

Aluminum foil 250×(0.02-0.035) 320×(0.02-0.035) 160×(0.02-0.035)

Tropicalized Aluminum 250×(0.09-0.15) 320×(0.09-0.15) 160×(0.09-0.15)

Overall dimensions(mm) 4300×635×1400 4800×718×1500 3800×680×1400

Part size(mm) 1600×635×1400 1600×718×1500 2530×680×1400

1600×635×1400 1600×718×1500 1270×680×1400

1100×635×1400 1600×718×1500

Weight(Kg) 2400 2000 1200

Send your inquiry to this supplier