1 / 6

Advanced Sack Placer/Bag Placer/Scale Bagging Machine for Pellets (SGJ-ZD)

Get Latest Price

Send Inquiry

| Model No. : | SGJ-ZD |

|---|

Hefei Sanguan Mechanical & Electrical Equipment Co., Ltd.

You might also like

Product description

Sack Placer/Bag Placer/Scale Bagging Machine

Applicable scope:

It's mainly applicable for powder, granules, slices of raw materials(such as PE, polypropylene, PVC, PVA etc), which will be packed into big bag automatically with several actions, including bag feeding, bag fetching, bag dischargeing, bag flatting at the clamping device, accounting, filling, discharging and edge-folded sealing etc. It can realize fully automatic operation.

Technical Parameters:

Model Package capability Package range Structure

ZD(F)800 800bags/h 10-50kg Cylinder driving

ZD(F)1000 1000bags/h 10-50kg Cylinder driving

ZD1200 1200bags/h 10-50kg Servo batteries Driving

ZD1600 1600bags/h 10-50kg Servo batteries Driving

(can design biger one as your requirment, the bigest can pack 1000kg per bag)

The Components:

Bag Container--Pallet Electronic Weigher--Tray Silo--Pallet Conveyor--Dedust--Air Filling

System

Product Features:

The automatic packing machine for big bags consists of color touch LCD operation panel, English menu display, working state display. It can set the parameters, and self-chek.

Bag feeder: The operator put the empty bags on the bag feeder, other action are completed by the machine. It explores double trays freely interchanging, each tray can store more than 200bags

(woven plastic bag or paper bag). When the tray is empty, the machine will self-check and alarm.

Bag container: This device will automatically fetch, bag open, self-check and filling the bags in continuity. After being weighed by the electronic weigher, the materials will be filled into the bag through the hopper and put on the conveyor. This machine can realize pneumatically bag clamping, bag being opened by vacuum acetabula, bag discarding being automatically checked by plus-minus pressure system.

Sewing point of the bag tider: It will finish bag tidying before sent to edge-folded sewing machine

Sewing edge-fold unit: It can be automatically edge folded and sewed(suitable for woven bag)

Sewing &HeaT-sealing Unit: It can automatically sewing&heaT-sealing

Stand-up Bag belt conveyor: It can convey the bag into next action position with bag standing up.

Processing:

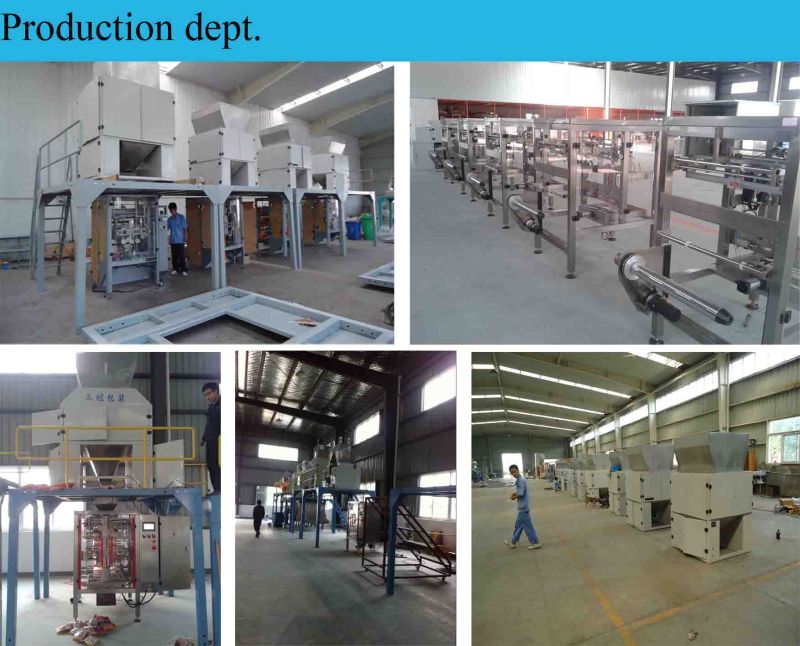

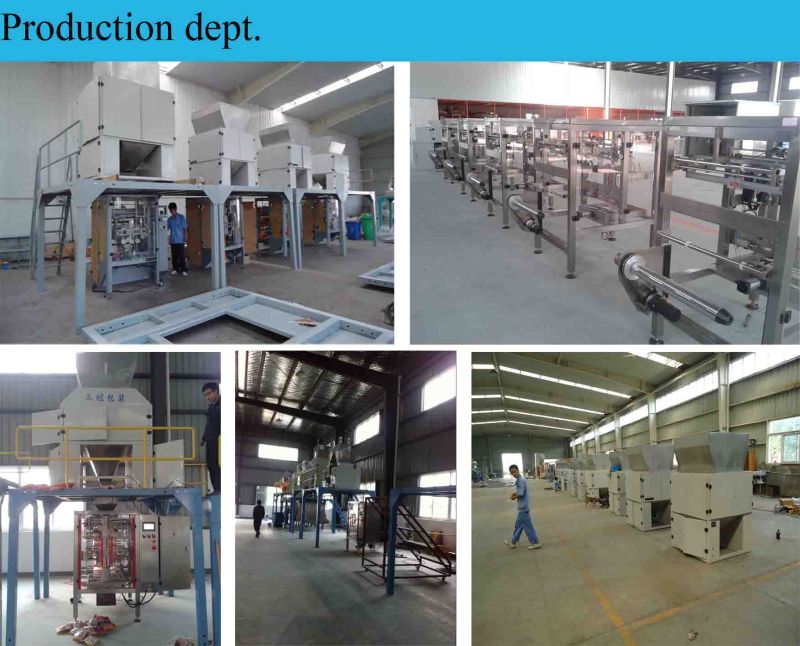

Partners:

After Sales Service:

1. One year warranty for the whole system.

2. Free equipment installation and debugging.

3. We can provide intenship service and help you train the operator and mechanic.

4. Free production technology and process configuration.

Applicable scope:

It's mainly applicable for powder, granules, slices of raw materials(such as PE, polypropylene, PVC, PVA etc), which will be packed into big bag automatically with several actions, including bag feeding, bag fetching, bag dischargeing, bag flatting at the clamping device, accounting, filling, discharging and edge-folded sealing etc. It can realize fully automatic operation.

Technical Parameters:

Model Package capability Package range Structure

ZD(F)800 800bags/h 10-50kg Cylinder driving

ZD(F)1000 1000bags/h 10-50kg Cylinder driving

ZD1200 1200bags/h 10-50kg Servo batteries Driving

ZD1600 1600bags/h 10-50kg Servo batteries Driving

(can design biger one as your requirment, the bigest can pack 1000kg per bag)

The Components:

Bag Container--Pallet Electronic Weigher--Tray Silo--Pallet Conveyor--Dedust--Air Filling

System

Product Features:

The automatic packing machine for big bags consists of color touch LCD operation panel, English menu display, working state display. It can set the parameters, and self-chek.

Bag feeder: The operator put the empty bags on the bag feeder, other action are completed by the machine. It explores double trays freely interchanging, each tray can store more than 200bags

(woven plastic bag or paper bag). When the tray is empty, the machine will self-check and alarm.

Bag container: This device will automatically fetch, bag open, self-check and filling the bags in continuity. After being weighed by the electronic weigher, the materials will be filled into the bag through the hopper and put on the conveyor. This machine can realize pneumatically bag clamping, bag being opened by vacuum acetabula, bag discarding being automatically checked by plus-minus pressure system.

Sewing point of the bag tider: It will finish bag tidying before sent to edge-folded sewing machine

Sewing edge-fold unit: It can be automatically edge folded and sewed(suitable for woven bag)

Sewing &HeaT-sealing Unit: It can automatically sewing&heaT-sealing

Stand-up Bag belt conveyor: It can convey the bag into next action position with bag standing up.

Processing:

Partners:

After Sales Service:

1. One year warranty for the whole system.

2. Free equipment installation and debugging.

3. We can provide intenship service and help you train the operator and mechanic.

4. Free production technology and process configuration.

Send your inquiry to this supplier

Send Inquiry