1 / 4

Activated Zinc Oxide Transparent Zinc Oxide Rubber Grade

| Brand Name : | DUBA |

|---|---|

| place of origin : | China |

Dongguan, Guangdong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Activated Zinc Oxide Transparent Zinc Oxide Rubber Grade

Description

In the rubber manufacturing industry, Activate Zinc Oxide is an ingredient that improves rubber stability, vulcanization speed, and bond strength, among other things. The activated zinc oxide range has the advantage of a high specific surface area (up to 45m²/g) which gives these products excellent vulcanization activator performance. This level of performance reduces ZnO consumption in rubber compounds by up to 40%, depending on the application, thereby reducing costs and heavy metal content.

Indirect method. Reaction equation: 2Zn+O2=2ZnO

Operation method: the zinc ingot obtained by the electrolysis method is heated to 600-700 ° C for melting, placed in a high temperature resistant crucible, and melted and vaporized at a temperature of 1250 to 1300 ° C, and introduced into hot air for oxidation, and the generated zinc oxide is cooled. The cyclone is separated, and the fine particles are collected by a bag to obtain a finished zinc oxide.

Direct method. Reaction Equation

C+O2=CO2

CO2+C=2CO

ZnO+CO=Zn(vapor)+CO2

Zn (vapor) + CO + O2 = ZnO + CO2

Method of operation: The calcined zinc ore powder (or zinc-containing material) is blended with anthracite (or coke) and limestone at a ratio of 1:0.5:0.05 to form a ball. After reduction and smelting at 1300 °C, zinc oxide in the ore powder is reduced to zinc vapor, and then oxidized by air, and the generated zinc oxide is collected to obtain a finished zinc oxide product.

Product Advantages

1. It is very suitable for transparent or translucent rubber products with extremely low zinc gas;

2. Ultrafine particles are easy to disperse in rubber, and the dosage is less than that of zinc oxide in the usual method (Fawang method);

3. Many applications of Active Zinc Oxide can be used as an anti-softening agent, which can make rubber ingredients not easily deformed, and can be used as a filler for light-colored rubber;

4. The tear resistance, tensile coefficient and wear resistance of rubber products are all improved;

5. The scale of sulfur addition is widened, and the risk of excessive sulfur addition can be greatly reduced.

Company Advantage

1. Real manufacturer, 20 years producer

2. Quality is superior to GB standard, free sample for your test before shipment

3. Expert sales & after-sale team, prompt shipment with professional documents

4. Chemical stability, SGS report

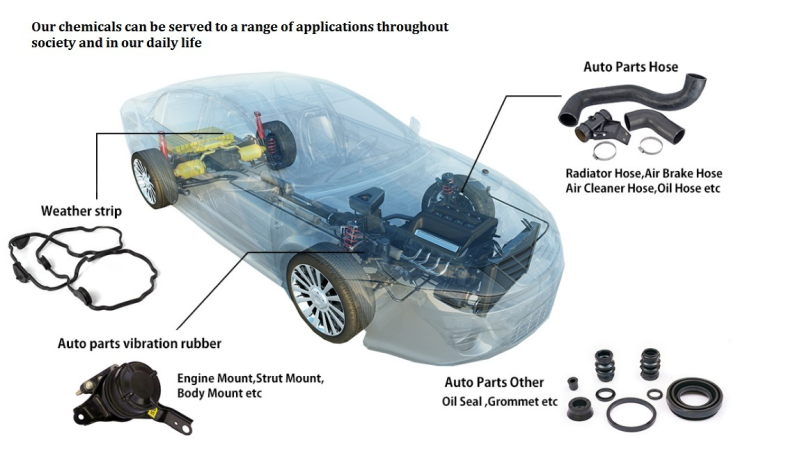

We are good specializing in manufacturing and marketing of high quality pre-dispersed Rubber Chemicals & Additives, widely used for automotive industry, footwears, cables, sports products etc.

With high quality and competitive price, our products have good sales in Europe, America, Southeast Asia, India, Brazil etc.

If needed Active Zno For Rubber, we can supply small qty sample for lab trial any time.

Welcome to send us inquiry!

Dongguan, Guangdong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier