Video

1 / 5

99.6% Al2O3 Alumina Ceamic Substrate

Options:

- 99.6% Alumina Ceramic substrates

- AlN substrate,Si3N4 substrate available

- Standard and customized spec. available

- Offer post-processing service

- Min. thickness to be 0.11mm

| Model No. : | Customized |

|---|---|

| Brand Name : | Jinghui ceramics |

| place of origin : | China |

Loudi, Hunan, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

99.6% Al2O3 Alumina Ceamic Substrate

99.6% alumina ceramic substrate offers better surface quality, higher thermocycling capability and thermal conductivity, mechchanical strength than 96% alumina ceramic ones, The kind of ceramic substrate is designed to meet the highest demand in thin-film technology.

In order to enhance the quality quality further, sometimes, The post-processing, such as fine lapping and polishing, will be conducted after firing. With these secondary process, both flatness and parallelism will be improved a lot. The improved will significantly benefit the ability to design denser circuits, the design of fine-pitch, high-density interconnect circuits. The improved parallelism will offer better capacitance and inductance of the substrate. Furthermore, polished ceramic substrate reduces the peak-to-valley amplitude of the surface, allowing the use of very thin metallization layers. Thinner resistive layers increase the sheet resistance of the material, which allows higher resistance values to be formed using thin film technology.

Specification of ceramic substrates

1. Shaping methods: tape casting, dry pressing, isostatic pressing, hot pressing and so on.

2. Material availability: aluminum oxide, zirconium oxide, silicon carbide, aluminum nitride optional

3. Typical thickness: 0.25 mm, 0.30 mm, 0.40 mm, 0.50 mm, 0.635 mm, 0.80 mm, 1.0 mm, 1.2 mm

4. Dimension capability: min. thickness to be 0.15 mm, max. length and width to be 400 mm x 300 mm

5. Dimensional tolerance : thickness ± 0.05 mm, length ± 0.20 mm, width ± 0.20 mm

6. Surface treatment: mirror - like polishing, metallizing for ceramic to metal bonding

7. Secondary process : laser cutting, fine grinding, high precision CNC machining and so on

Main features of alumina ceramic substrates

1. High thermal conductivity, up to 31 W/m.k at room temperature and low coefficient of thermal expansion

2. Good thermal shock resistance, greater than 220 T(℃) and refractory with high - temperature resistance

3. Good surface roughness, flatness to be 0.05 mm and very smooth texture with super tiny grain size

4. High dielectric strength, high electrical resistivity, low dielectric constant and dielectric loss.

5. Laser cutting or precision machining cutting makes tight tolerance for precision fitting easily

6. More quicker heat dissipation than cooper and aluminum metal materials and increase the service life

7. Anti-aging, resistance to oxidization and free of rusty forever, also chemical stability to various harsh conditions

8. Low density, over 3.75 g /cm3, with light weight, it's benefit to design the device more lighter.

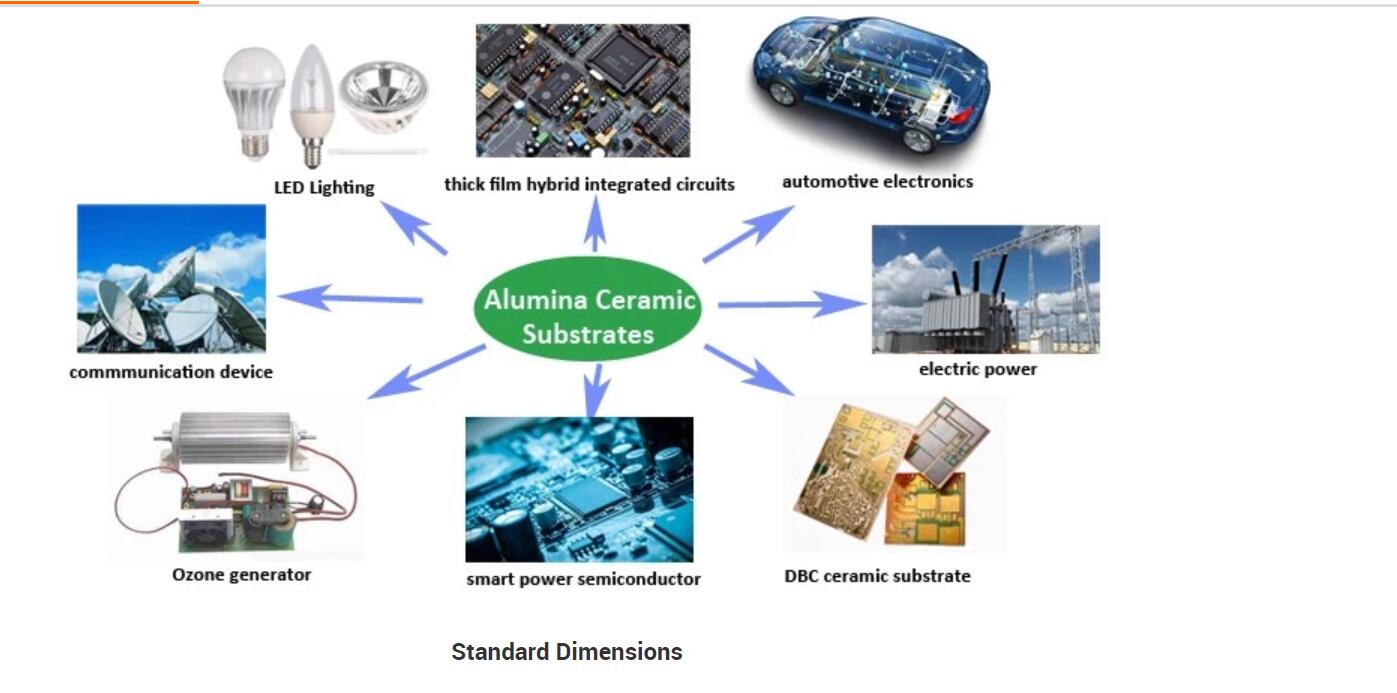

Application of alumina ceramic substrates

Alumina ceramic substrates are widely used in power modules, LED lighting, power semiconductor, automotive electronics, DBC ceramic substrate

Standard size of stock alumina ceramic substrates

Remark:

1. All big ceramic alumina substrate in above list can be cut to small size sheet, small size plate.

2. Some of above alumina ceramic substrates are made of 96% purity aluminium oxide, or 99%.

Why choose us?

1. 10+ Years of manufacturing experience in OEM, ODM and professional teams

2. Powerful R&D, mass production capability

3. In-house comprehensive manufacturing equipment from forming to machining

4. Rigorous quality control system and processes

5. Surpassing pre-sales,sales & after-sales service, flexible and on-time delivery

Video

Loudi, Hunan, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier