1 / 6

55 Liters Tangential Type Kneader

| Model No. : | LN-TT-55 |

|---|---|

| Brand Name : | LINA |

| PLC : | Mitsubishi |

Dongguan, Guangdong, China

- Manufacturer

- Platform Certification

- SGS Certification

- Video

Product description

LINA 55 Liters Tangential Type Dispersion Kneader with Automatic Tilting Device

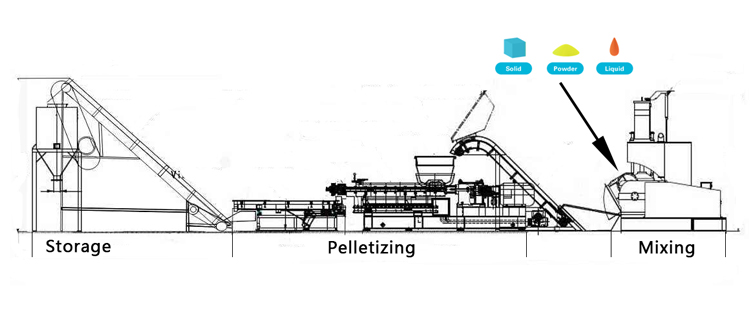

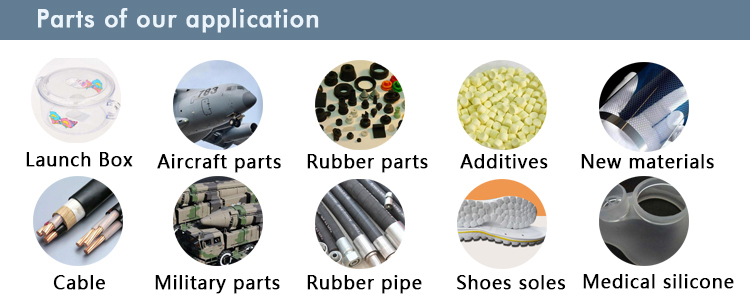

This type of 55 Liters Tangential Type Kneader Rubber Mixer with Different Rotors are able to meet the big demand in today's industry and market. LINA Tangential Type Rotor Rubber Dispersion Kneader's rotor must be driven by a constant speed connecting gear, the large diameter of one rotor interacts with the small diameter of the opposite. There is ridges on the rotor, the ridges are helically shaped along the rotor to allow the mixing material to move axially within the mixing chamber. Dispersion mixing is mainly carried out in a small gap between two size rotors, the surface that directly contact with the materials can be mirror polished which ensures all the materials easy to be cleaned without stickiness and avoid formula lost and pollution. Besides, LINA Tangential Kneader for Rubber Mixing are using high hardness materials, Tungsten carbide can be plated on the surface of rotors and mixing chamber to avoid damage of important parts.

Characteristics of LINA 55L Tangential Type Dispersion Kneader

1.Eco-friendly.

2.Precise temperature control

3.Suitable for a wide range of materials.

4.Excellent dispersion effect.

5.Easy cleaning for different materials.

6.Better performance dust seal for preventing material leak.

Specifications of LINA 55 Liters Tangential Type Dispersion Kneader

remarks

Tangential Type

50-70 KG per time

75 KW

About 3300*2000*3100mm

Item

Specification

Type

Mixing Capacity

55 liter

Production Yield

Subject to the proportion of material and dispersion

requirements.

Main Motor Power

Flipping Method

Hydraulic type

Flipping Angle

110°

Temperature Control

Heating or/and cooling

Electric/oil/steam heating and circulating water

cooling.

Weight

About 7800 KG

Dimensions

Details of LINA 55 Liters Tangential Type Dispersion Kneader

LINA After-Sales Services

1. On-site installation assistance is available. (There are no charges on installation and trial running, but VISA fees, accommodation fees and transportation fees etc. of the supplier's side are charged by the buyer.)

2. Training of customer's operators and maintenance personnel and long-term technical consultation is provided.

3. One year's non-charge warranty period is provided for units in normal operation and long-term spare parts/components are available. During the warranty period, the supplier, within three hours since receipt of purchaser's notice of any equipment fault, shall provide express solution, and, if necessary, assign service engineer(s) to site across China within 72 hours or site in Pearl River Delta within 5 hours (excluding travel time). Response time for customers overseas shall be agreed upon otherwise based on application for visa and accessibility to the customer's location.

Are you factory or trading company?

LINA Machinery has been engaged in Rubber & Plastic mixing machine for many years. We have workshop and R&D department.

What about the operational guideline?

Training of customer's operator and maintenance personnel and long-term technical consultation is provided.

How about the warranty time?

One year's non-charge warranty period is provided for units in normal operation and long-term spare parts/component are available.

Do you offer the customization of the machine?

Certainly, LINA will give you the most proper recommendation and setting according to your materials and demand.

Dongguan, Guangdong, China

- Manufacturer

- Platform Certification

- SGS Certification

- Video

Send your inquiry to this supplier