Video

1 / 1

300ml 500ml 1L 2L Automatic Stretch pe Bottle Blow Molding Machine Plastic Preform

$2500.00

~ $20000.00

/ Set/Sets

Options:

- 15-300

Send Inquiry

| Brand Name : | Jtscrew |

|---|

More

9yrs

Zhoushan, Zhejiang, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Zhejiang Jinteng Machinery Manufacture Co., Ltd.

You might also like

Product description

COMPANY PROFILE

With the development of 20 years, Zhejiang Jinteng Machinery Manufacture, which located in the Jintang town, Dinghai district, Zhoushan city, Zhejiang province has became one of the biggest professional screw and barrel manufacturer.

COMPANY TENET

1.Honesty

2.The Quality of Businesses

3.Improvement

4.The Pursuit of Excellence

PRODUCT DETAILS

Product description and introduction

1. short time for changing the color of die head is treated by deep mirror, and the curve channel is smooth without dead Angel.

2. Special design of die head: it is convenient to change material, change color, discharge slag, disassemble and clean. Die head internal precision machining, good sealing performance,

3.High degree of automation: can be equipped with overflow removal device, in-mold labeling, manipulator to take bottles, finished conveyor belt, leakage detection machine.

4.According to the user's requirements, you can choose splitter shuttle, screw or glue type die head.

5.Optimize hydraulic oil circuit design, power saving, fast action, convenient parameter adjustment, double ratio control oil flow rate and pressure, directional valve control flow direction,deceleration valve brake, smooth and fast action.

6.The force design of tthe template center ensures the uniformity of the clamping force, The guide column is made of high quality alloy, which is formed by adjusting and tempering, processing, nitriding, cylindrical grinding, electroplating and other process, It's has the advantages of wear resistance, good toughness and long service life.

7.Energy-saving power design: variable frequency motor is used to drive the screw, and the main hydraulic system is controlled by servo motor, which is 15-30% more energy-saving than ordinary motor.

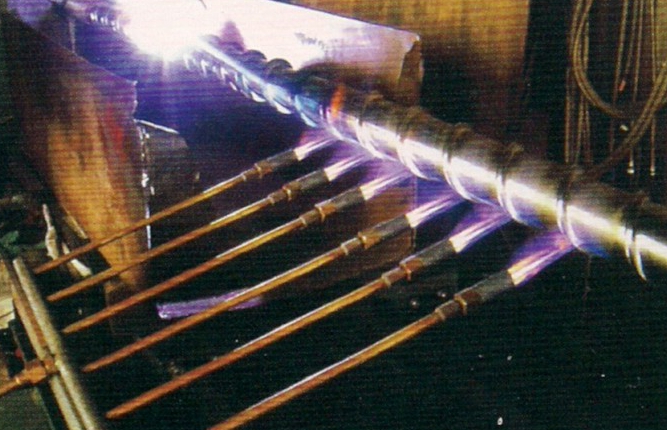

PRODUCTION WORKSHOP

Advanced equipment ensure JINTENG quality,JINTENG has a good supplier over the world. JINTENG has 4-axis CNC machining centers. CNC boring machine, CNC milling machine, CNC deep hole boring machine, hervy lath with 10M length.

CNC Screw milling

Gringding inside holes

8 Meters pit tempering furnace

8 Meters pit nitriding

The raw material of each screw set is carefully examined before and after processing.

BIMETALLIC LAYER

PACKING & SHIPPING

Export standard wooden case

1: Special oil

2: PE film wrap

3: Plywood case

Video

Supplier's popular products

9yrs

Zhoushan, Zhejiang, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier

Send Inquiry