1 / 7

25 Liters Environmental Air Isolated Internal Mixer

| Model No. : | LN-AI-25 |

|---|---|

| Brand Name : | LINA |

| PLC : | Mitsubishi |

Dongguan, Guangdong, China

- Manufacturer

- Platform Certification

- SGS Certification

- Video

Product description

LINA 25 Liters Sensitive Material Air Isolated Laboratory Used Dispersion Kneader

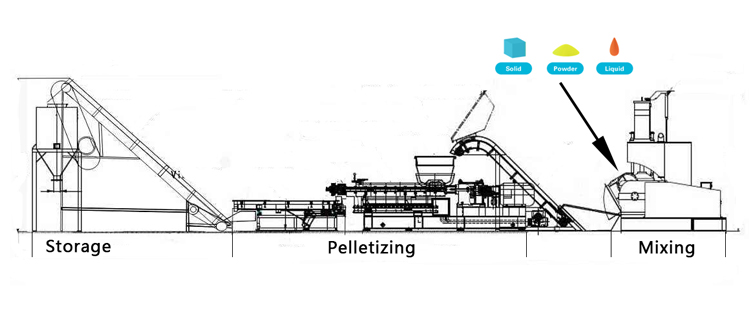

LINA Eco-Friendly Dispersion Mixers for Sensitive Material new design directly with the materials can be mirror polished which ensures all the materials easy to be cleaned without stickiness and avoid formula lost and pollution. LINA Environmental Protection Air Isolated Kneader are suitable for a wide range of sensitive materials with different physical characteristics. For Toxic gas, expensive material and any other sensitive material. Surface of rotors and mixing chamber to avoid damage of important parts and ensure searing effect and the material is kneading and pelletizing in a very low oxygen or oxygen-free state. Air Isolated Kneader, Rubber Air Isolated Internal Mixer, Plastic Air Isolated Dispersion Kneader, Dispersion Kneader, Sensitive Material Dispersion Mixer

Characteristics of LINA 25 L Sensitive Material Isolated Dispersion Internal Mixer

1. In the premise of ensuring no oil and was water leak and easy cleaning, LINA designed the hydraulic coaxial separation technology.

2. Double gas protection design, within kneading and pelletizing process, material's physical properties will change due to different temperature zones, the double gas protection design is adopted to achieve the purpose of protecting material's physical property.

3. Suitable for discolored special ceramic feeding like high-quality titanium / aluminum / copper / nickel and other metal alloy formula synthesis and granulation.

4. Wearable inner cavity was imported special new alloy steel and vacuum heat treatment are adopted. Strong wear resistance, resistance to horizontal erosion, corrosion resistance .

5. The speed ratio of rotors is adjustable, which target at some special material function requirements and achieve best dispersion effect and efficiency.

Specifications of LINA 25 Liters Eco-friendly Air Isolated Dispersion Kneader without Oxygen

|

Item |

Specification |

Remarks |

| Type |

Air Isolated Type |

|

|

Mixing Capacity |

25 liters |

|

|

Production Yield |

20-35 KG per time |

Subject to the proportion of material and dispersion

requirements. |

|

Main Motor Power |

30/37 KW |

|

| Maximum Separation | / |

|

|

Temperature Control |

Heating or/and cooling |

Electric/oil/steam heating and circulating water

cooling. |

|

Weight |

About 4200 KG |

|

|

Standard Dimensions |

About 2450*1600*2550 mm |

|

|

Eco Type Dimensions |

About 2550*1680*2680 mm |

|

Details of LINA 25 Liters Sensitive Material Air-Isolated Dispersion Kneader

LINA After-Sales Services

1. On-site installation assistance is available. (There are no charges on installation and trial running, but VISA fees, accommodation fees and transportation fees etc, of the supplier's side are charged by the buyer.)

2. Training of customer's operators and maintenance personnel and long-term technical consultation is provided.

3. One year's non-charge warranty period is provided for units in normal operation and long-term spare parts/components are available. During the warranty period, the supplier, within three hours since receipt of purchaser's notice of any equipment fault, shall provide express solution, and, if necessary, assign service engineer(s) to site across China within 72 hours or site in Pearl River Delta within 5 hours (excluding travel time). Response time for customers overseas shall be agreed upon otherwise based on application for visa and accessibility to the customer's location.

Are you factory or trading company?

LINA Machinery has been engaged in Rubber & Plastic mixing machine for many years. We have workshop and R&D department.

What about the operational guideline?

Training of customer's operator and maintenance personnel and long-term technical consultation is provided.

How about the warranty time?

One year's non-charge warranty period is provided for units in normal operation and long-term spare parts/component are available.

Do you offer the customization of the machine?

Certainly, LINA will give you the most proper recommendation and setting according to your materials and demand.

Dongguan, Guangdong, China

- Manufacturer

- Platform Certification

- SGS Certification

- Video

Send your inquiry to this supplier