1 / 3

2014 Cheap 20W 40 60W Bhy Explosion Proof LED Derrick Light, LED Frame Light

Get Latest Price

Send Inquiry

| Model No. : | LED Derrick Light |

|---|

Zhejiang Haiyangwang Explosion-Proof Electric Co., Ltd.

You might also like

Product description

2014 20w 40 60w BHY-L Explosion Proof LED Derrick Light,LED Frame Light

Applicable place:

Apply to chemical, oil-refining, oil exploration, offshore oil platforms, cruise ships, textile, pharmaceutical, oil depots, docks, aerospace, military and other hazardous area lighting applications.

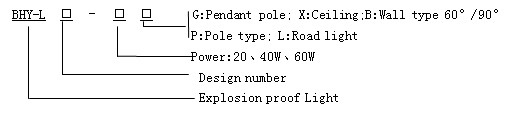

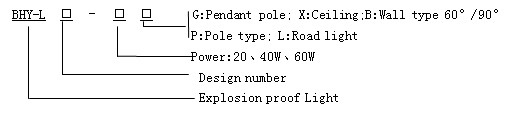

Product type meaning:

Main technical parameter of explosion-proof lights

Main technical parameter of explosion-proof lights

Rated voltage: AC176-277V;

Rated power: 20W, 40W, 60W;

Protection class: IP65;

Mark: Excmb II T6;

Anticorrosion class: WF2;

Inlet thread size: G3/4;Cable diameter: φ 10~ 12mm;.

Product dimensions

BHY-LED20 dimensions (mm): L322*W120*H100

BHY-LED40 dimensions (mm): L622*W120*H100

BHY-LED60 dimensions (mm): L922*W120*H100

Explosion-proof lights work reliably in the following conditions

A) ambient air temperature is-20ºC~+40ºC, and the average temperature does not exceed + 24h 35 ºC;

B) installation place the highest temperature is + 40 ºC, relative humidity of air no more than 95%;Lower temperatures can be allowed to have a higher relative humidity.

The main structure

Explosion-proof light shell is made of cast aluminum alloy die casting and molding aluminum melting and molding, casting of aluminum alloy surface is sprayed with plastics, surface matte anodized overall the light sources composed Chamber and the power Chamber.Light source cavity within the main install LED light sources, reflectors, power main installation cavity LED lamp driver power supply, grounding screw, and so on.Within the cable entry device of inlet-outlet from the inside to the outside with seals, gaskets and press nuts, for cable or pipe routing.

Main features:

1.Design of PWM switching power supply using pulse width modulation technique: high reliability, stability, high efficiency and low consumption.Voltage AC176~277V changes, are able to work steadily, LED lights glow effect.

2.Power supply protection: overload, overvoltage, overcurrent, short circuit, ensure the safety of power supply and LED lamps.

3.LED service life of up to 50,000 hours, 5-10 times that of other light sources.

4.LED light sources, high efficiency and energy saving, low power, same illumination than traditional light energy-saving 80%, same 5-7 times more power than traditional light, is the best choice for energy saving;

5.Green;LED light is made from nontoxic materials, unlike fluorescent lamps containing mercury pollution caused by heavy metals.

6.Power supply enclosure made of aluminum alloy materials, and using Super cooling structure, its temperature ≤ 30, explosion-proof light the highest surface temperature at ambient temperature to 40 ºC, does not exceed 70 ºC, are properly secure work.

7.Power supply of electronic components using epoxy resin sealed aluminium casing, completely preventing the effects of moisture and condensation, so as to effectively reduce the incidence of failure.

8.Per 20 LED lamp bead series explosion-proof lights into a group, divided into 3 parallel form.

9.Explosion-proof lights designed light source cavity with threaded flameproof and casting type LED lamp power supply, two-Chamber shell connections using a special seal, mounting screws power cavity prevention measures.

10.Using ultra high light transmission rate and high reflectivity mirrors toughened glass, make illumination higher, brighter lighting and clear.

11.Solid-state lighting, shock well.

Use and maintenance

1.Installation, bringing Chamber cover and the power supply to the device turned on, according to the select the appropriate sealing ring outer diameter of the cable diameter, then passes through the introduction of cable clamping nuts, washers and seals the device connected to the terminal block and tighten clamp nut cable glands, connect the grounding wire, close the lid, fastened good bolt (screw).Available after the above check.

2.Repair, disconnect power from the level before the explosion-proof lights and maintenance opening.

Applicable place:

Apply to chemical, oil-refining, oil exploration, offshore oil platforms, cruise ships, textile, pharmaceutical, oil depots, docks, aerospace, military and other hazardous area lighting applications.

Product type meaning:

Main technical parameter of explosion-proof lights

Main technical parameter of explosion-proof lightsRated voltage: AC176-277V;

Rated power: 20W, 40W, 60W;

Protection class: IP65;

Mark: Excmb II T6;

Anticorrosion class: WF2;

Inlet thread size: G3/4;Cable diameter: φ 10~ 12mm;.

Product dimensions

BHY-LED20 dimensions (mm): L322*W120*H100

BHY-LED40 dimensions (mm): L622*W120*H100

BHY-LED60 dimensions (mm): L922*W120*H100

Explosion-proof lights work reliably in the following conditions

A) ambient air temperature is-20ºC~+40ºC, and the average temperature does not exceed + 24h 35 ºC;

B) installation place the highest temperature is + 40 ºC, relative humidity of air no more than 95%;Lower temperatures can be allowed to have a higher relative humidity.

The main structure

Explosion-proof light shell is made of cast aluminum alloy die casting and molding aluminum melting and molding, casting of aluminum alloy surface is sprayed with plastics, surface matte anodized overall the light sources composed Chamber and the power Chamber.Light source cavity within the main install LED light sources, reflectors, power main installation cavity LED lamp driver power supply, grounding screw, and so on.Within the cable entry device of inlet-outlet from the inside to the outside with seals, gaskets and press nuts, for cable or pipe routing.

Main features:

1.Design of PWM switching power supply using pulse width modulation technique: high reliability, stability, high efficiency and low consumption.Voltage AC176~277V changes, are able to work steadily, LED lights glow effect.

2.Power supply protection: overload, overvoltage, overcurrent, short circuit, ensure the safety of power supply and LED lamps.

3.LED service life of up to 50,000 hours, 5-10 times that of other light sources.

4.LED light sources, high efficiency and energy saving, low power, same illumination than traditional light energy-saving 80%, same 5-7 times more power than traditional light, is the best choice for energy saving;

5.Green;LED light is made from nontoxic materials, unlike fluorescent lamps containing mercury pollution caused by heavy metals.

6.Power supply enclosure made of aluminum alloy materials, and using Super cooling structure, its temperature ≤ 30, explosion-proof light the highest surface temperature at ambient temperature to 40 ºC, does not exceed 70 ºC, are properly secure work.

7.Power supply of electronic components using epoxy resin sealed aluminium casing, completely preventing the effects of moisture and condensation, so as to effectively reduce the incidence of failure.

8.Per 20 LED lamp bead series explosion-proof lights into a group, divided into 3 parallel form.

9.Explosion-proof lights designed light source cavity with threaded flameproof and casting type LED lamp power supply, two-Chamber shell connections using a special seal, mounting screws power cavity prevention measures.

10.Using ultra high light transmission rate and high reflectivity mirrors toughened glass, make illumination higher, brighter lighting and clear.

11.Solid-state lighting, shock well.

Use and maintenance

1.Installation, bringing Chamber cover and the power supply to the device turned on, according to the select the appropriate sealing ring outer diameter of the cable diameter, then passes through the introduction of cable clamping nuts, washers and seals the device connected to the terminal block and tighten clamp nut cable glands, connect the grounding wire, close the lid, fastened good bolt (screw).Available after the above check.

2.Repair, disconnect power from the level before the explosion-proof lights and maintenance opening.

Send your inquiry to this supplier

Send Inquiry