1 / 5

10-20% Energy Saving Ball Mill Machine

| Model No. : | GM0912 |

|---|---|

| Brand Name : | Jiangxi Henghong |

| Type : | Ball Mill |

Ganzhou, Jiangxi, China

- Manufacturer

- Service

- Trade Company

- OEM service

- Platform Certification

Product description

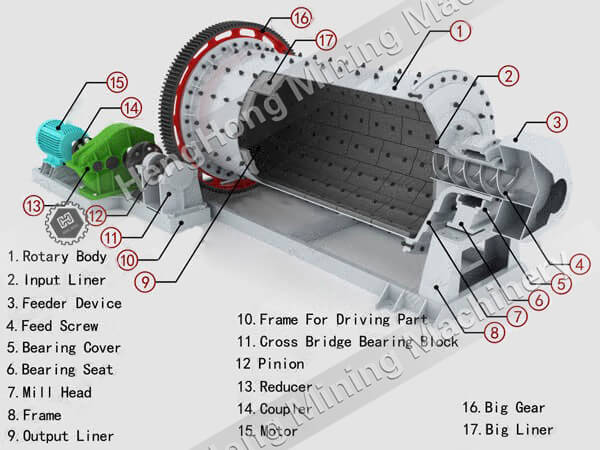

Working Principle

Ball mill is the key equipment for pulverizing materials after crushing. When ball mill start working, the motor drives the gear and cylinder shell to rotate via reduction device. The material and steel balls will be brought to a certain height by centrifugal force. The steel balls will grind the material when they flow down. The finished materials are discharged through the discharging board. The the grinding process is finished.

Ball mill is mainly consisting of motor, reduction device, big gear and small gear, cylinder shell, liner, steel balls, support device, etc.

Application

Ball mill as a key grinding equipment in industries, widely applied to the powder-making production line, such as cement, silicate product, new building materials, refractory materials, fertilizer, ore dressing of ferrous metal and non-ferrous metal, and glass ceramic, etc. It can carry out dry or wet pulverizing of various and other pulverizable materials.

Features

- Low energy consumption

- High working efficiency

- Large processing capacity

Technology Parameter List

| Model | Cylinder Size (mm) | Revolution of cylinder | Weight with balls | Feeding Size | Capacity | Cooperate Motor | Weight | ||

| Diameter | Length | (r/min) | (t) | (mm) | (t/h) | Model | Power (kw) | (kg) | |

| GM0912 | 900 | 1200 | 41.6 | 1.1 | 25 | 0.3~0.9 | Y180L-8 | 11 | 4210 |

| GM0921 | 900 | 2100 | 41.6 | 1.8 | 25 | 0.6~1.5 | Y180L-6 | 15 | 6660 |

| GM1224 | 1200 | 2400 | 35.1 | 4 | 0~25 | 1.6~4.1 | Y280S-8 | 37 | 10020 |

| GM1228 | 1200 | 2800 | 35.1 | 4.6 | 0~25 | 1.9~4.8 | Y280M-8 | 45 | 10935 |

| GM1232 | 1200 | 3200 | 35.1 | 5.3 | 0~25 | 2.2~5.5 | Y280M-8 | 45 | 11230 |

| GM1245 | 1200 | 4500 | 30.2 | 6.8 | 0~25 | 3.3~8.2 | Y315S-8 | 55 | 13210 |

| GM1324 | 1300 | 2400 | 30.2 | 4.5 | 0~25 | 1.5~3.5 | Y280S-8 | 37 | 10210 |

| GM1328 | 1300 | 2800 | 30.2 | 5.2 | 0~25 | 1.7~4.4 | Y280M-8 | 45 | 11290 |

| GM1334 | 1300 | 3400 | 30.7 | 6.2 | 0~25 | 2.0~5.2 | Y280M-8 | 75 | 13111 |

| GM1524 | 1500 | 2400 | 30.7 | 5.8 | 0~25 | 2.3~5.7 | Y315S-8 | 55 | 15430 |

| GM1530 | 1500 | 3000 | 30.7 | 7.3 | 0~25 | 3.1~7.3 | Y315M-8 | 75 | 16843 |

| GM1533 | 1500 | 3300 | 30.7 | 8 | 0~25 | 3.5~8.0 | JR125-8 | 80 | 17849 |

| GM1536 | 1500 | 3600 | 30.7 | 8.7 | 0~25 | 3.9~8.8 | JR125-8 | 80 | 18649 |

| GM1542 | 1500 | 4200 | 30.7 | 10.2 | 0~25 | 4.3~9.4 | JR126-8 | 110 | 19330 |

| GM1545 | 1500 | 4500 | 30.7 | 10.9 | 0~25 | 4.8~10.8 | JR126-8 | 110 | 20000 |

| GM1557 | 1500 | 5700 | 30.7 | 13.8 | 0~25 | 6.1~14 | JR127-8 | 130 | 23597 |

| GM1563 | 1500 | 6300 | 30.7 | 15.3 | 0~25 | 6.5~15 | JR128-8 | 155 | 24390 |

| GM1830 | 1800 | 3000 | 25.04 | 10.8 | 0~25 | 2.4~10 | JR127-8 | 130 | 24490 |

| GM1834 | 1800 | 3400 | 25.04 | 12.3 | 0~25 | 2.6~11 | JR128-8 | 155 | 30390 |

| GM1836 | 1800 | 3600 | 25.04 | 13 | 0~25 | 2.7~12 | JR128-8 | 155 | 31600 |

| GM1842 | 1800 | 4200 | 25.04 | 15.2 | 0~25 | 3.3~15 | JR136-8 | 180 | 33490 |

| GM1864 | 1800 | 6400 | 25.04 | 23.2 | 0~25 | 5.1~23 | JR137-8 | 210 | 42440 |

| GM2130 | 2100 | 3000 | 23.8 | 14.3 | 0~25 | 4.0~30 | JR136-8 | 180 | 41960 |

| GM2136 | 2100 | 3600 | 23.8 | 17.1 | 0~25 | 5.0~37 | JR137-8 | 180 | 44550 |

| GM2140 | 2100 | 4000 | 23.8 | 19.1 | 0~25 | 5.2~39 | JR138-8 | 245 | 46690 |

| GM2145 | 2100 | 4500 | 23.8 | 21.4 | 0~25 | 5.6~42 | JR138-8 | 245 | 49230 |

| GM2170 | 2100 | 7000 | 23.8 | 29.2 | 0~25 | 5.9~80 | JR158-8 | 380 | 59610 |

| GM2265 | 2200 | 6500 | 21.4 | 34 | 0~25 | 6~67 | JR158-8 | 380 | 64800 |

| GM2436 | 2400 | 3600 | 23 | 20.6 | 0~25 | 6.4~81.5 | JR1410-8 | 280 | 63680 |

| GM2445 | 2400 | 4500 | 23 | 25.1 | 0~25 | 7.9~99.2 | JR158-8 | 380 | 72280 |

| GM2464 | 2400 | 6400 | 23 | 36.7 | 0~25 | 11.2~131 | JR1510-8 | 475 | 86180 |

| GM2736 | 2700 | 3600 | 21.7 | 28.4 | 0~25 | 15~115 | JR158-8 | 475 | 88400 |

| GM2742 | 2700 | 4200 | 21.7 | 33.1 | 0~25 | 17.5~135 | JR1512-8 | 570 | 90420 |

| GM3036 | 3000 | 3600 | 19.5 | 32.8 | 0~25 | 11~71.3 | TDMK570-32 | 570 | 10200 |

| GM3070 | 3000 | 7000 | 19.5 | 63.77 | 0~25 | 23~123.2 | TDM1250-36 | 1250 | 15700 |

| GM3230 | 3200 | 3000 | 18.7 | 33.2 | 0~25 | 50~90 | TDMK500-32 | 500 | 12400 |

| GM3236 | 3200 | 3600 | 18.5 | 37.5 | 0~25 | 18~135 | TDMK630-32 | 630 | 13900 |

| GM3245 | 3200 | 4500 | 18.7 | 65 | 0~25 | 100~145 | TDMK630-32 | 630 | 14500 |

| GM3290 | 3200 | 9000 | 18.5 | 93.69 | 0~25 | 28~217 | TDMK140-36 | 1400 | 17100 |

| GM3645 | 3600 | 4500 | 17.3 | 61.8 | 0~25 | 23~197 | TDMK1250-36 | 1250 | 15200 |

| GM3690 | 3600 | 9000 | 17.3 | 123.5 | 0~25 | 31~345 | TDMK1600-36 | 1600 | 22700 |

| GM4070 | 4000 | 7000 | 16.7 | 115.4 | 0~25 | 30~320 | TDMK2000-36 | 2000 | 35000 |

Our Company

Jiangxi Henghong international Mining Machinery Manufacturing Co.,Ltd is the leader of mining processing equipment manufacturer in China. We covers an area of 20,000 square meters and maintain a strong competitive position in the world by professional scientific, above 60 technological personnel and more than 150 staff, having more than 30 sets of heavy processing equipment and with an annual outpurt of more than 2000 sets of mining machinery.

Experienced mining machinery manufacturer

Our distinctive prodcts include Shaking table, Jig, Spriral separator, Gold concentrator, Ball mill, Jaw crusher, Flotation, Magnetic separator, Feeder, Classifier, Ore washing machine and Lab equipment ect. Our machines are popular in separating GOLD, copper, manganes, chrome, tungsten, tin, nickel, iron, titanium, lead, zinc, tantalum and some non-ferrous metals like quart, zircon, barite, ect.

HENGHONG SERVICE

--- PRE-SALE SERVICE ---

1. Based on clients` request and budget, HENGHONG experts will strictly make efficient, reliable solutions accordingly;

2. Mine sample testing is available, we welcome the customer send the sample to us for testing by courier, or, the customer take the sample to our factory for testing;

3. Design and provide the complete processing flowchart;

4. Design & manufacturer products according to clients` demands.

--- AFTER-SALE SERVICE ---

1. Pre-check and test the products before delivery;

2. Deliver the whole plant design for our clients which including infrastructure, electrical system and pipeline system design;

3. Trace the status of the shipping until the products received;

4. Prepare required documents to let clients pass custom clearance;

5. Dispatch experts to carry out below service on site:

1) Installation & debug of the machinery

2) Train the first-line operators & technical personnel

3) Carry out any other service clients may need

6. Provide technical exchanging & spare parts for life-long term

--- ONE STOP SOLUTION ---

1. Starting by running the mineral beneficiation experiment. To provide our clients with the best solution accordingly;

2. Besides supply the flowchart design & equipment, we also provide the infrastructure design; Electrical & pipeline system design, etc. To help our clients complete the design of the whole plant;

3. After the installation, debugging of the equipment, the official production will also be guiding by our experienced engineers on site, to guarantee the output minerals perfectly meet your demands.

Ganzhou, Jiangxi, China

- Manufacturer

- Service

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier