Video

1 / 6

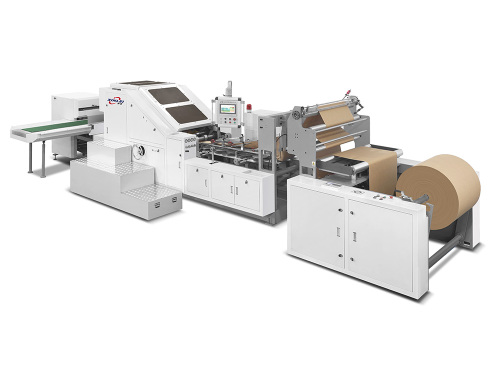

XinLei Automatic Square Bottom Paper Bag Machine

Get Latest Price

Send Inquiry

| Model No. : | XL-FD330 |

|---|---|

| Applicable industry : | Hotels,Garment Shops,Manufacturing Plant,Machinery Repair Shops,Food &Amp; Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Food &Amp; Beverage Shops,Advertising Company |

More

3yrs

Wenzhou, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Zhejiang Xinlei Machinery Co. Ltd

You might also like

Product description

Performance and use:

This machine is used for rolls of primary color paper or printing rolls such as kraftpaper, food paper and other paper rolls. This machine completes the paper bagprocess at one time. DThe window opening part is completed by unwinding,window opening, filming, edge glue, forming, cutting and indentation, bottomopening and bottom gluing, folding bottom forming, and finished bag finishing,The Paige bag part is completed by unwinding, patching, edge glue, forming,punching and cutting, bottom indentation and folding, bottom glue forming, andfinished bag finishing in one time. This machine is more convenient to operate, moreefficient, and more stable. It is an environmentally friendly paper bag machine equipment for producing various paper bags, snack food bags, bread bags, driedfruit bags, etc.

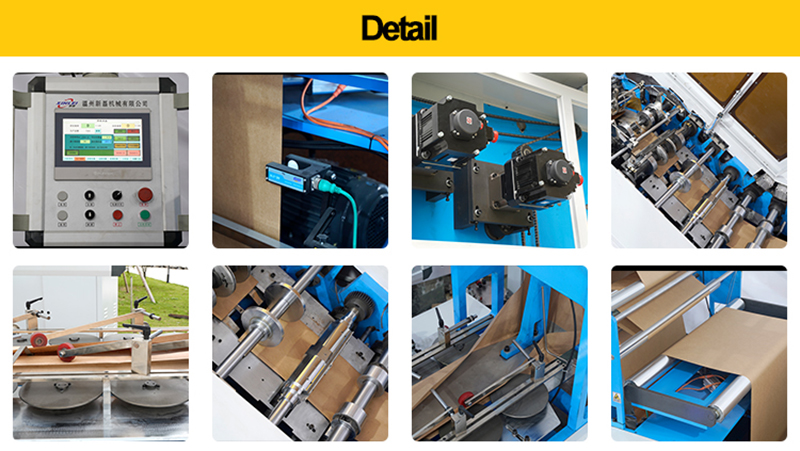

Main feature:

1.Using Willon touch screen man-machine interface, the operation function is clear at a glance, easy to control

2.Adopt the Japanese original Mitsubishi motion controller, through the integration with the optical fiber, operation stability

3.Japanese Mitsubishi servo motor with German Schick color standard eye correction, accurate tracking printing bag size

4.The raw material loading and unloading adopts hydraulic dynamic lifting structure, and the unwinding adopts automatic constant tension control.

5. The raw material correction adopts brushless servo motor to reduce the adjustment time of paper roll alignment.

Technical parameters:

|

Model

|

XL-FD330(W+D)

|

|

Cutting Length

|

270-530mm

|

|

Paper Bag Width

|

120-330mm

|

|

Holation width

|

50-120mm

|

|

Holation height

|

50-120mm

|

|

Bag bottom width

|

60-180mm

|

|

Pky bag width

|

190-330mm

|

|

Pky Bag Wrist hole

|

75/85mm

|

|

Paper thickness of the patch bag

|

80-150g/㎡

|

|

Pky bag film thickness

|

30-60um

|

|

Pky bag roll Widwidth

|

130mm

|

|

Piky Bag Paper Bag Speed

|

30-120pcs/min

|

|

Mechanical speed

|

30-200pcs/min

|

|

Paper bag speed

|

30-150pcs/min

|

|

Paper roll width

|

380-1050mm

|

|

Bar window Size

|

60-150mm

|

|

Paper Material Diameter

|

1200mm

|

|

Complete power

|

380v 3phase 4line 50.4kw

|

|

Operating Machine Weight

|

10000kg

|

|

Complete machine size

|

15500*4200*2000mm

|

Video

3yrs

Wenzhou, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier

Send Inquiry