Video

1 / 6

XD-100 10000L to 15000 liters Sewage Suction Truck Vacuum Pumps for sale

$660.00

≥1 Set/Sets

$640.00

≥10 Set/Sets

$620.00

≥20 Set/Sets

Maximum flow rate:

- 50-120

Options:

- Sump Pumps

- SEWAGE PUMPS

- Effluent Pumps

- Self-Priming Sewage & Trash Pumps

- Circulating Pumps

- 7m

- 10

| Brand Name : | Clw |

|---|

Suizhou, Hubei, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

Product description

XD-100 10000L to 15000 liters Sewage Suction Truck Vacuum Pumps for sale

1, Accessories warranty for 12 months,Besides, we can give assistance in the following days by email or telephone. If necessary, your network engineer could go for technical assistance.

2,We will provide customers with the mos economical design according to the loading equipment and the payload.ODM & OEM customize, professional and technical team provide you the best design , free logo print.Trailer assembled under strict quality control, any process is inspected .

3,With years of export experience along with excellent quality, advanced services and competitive prices, Chengli truck has won numerous customers' trust and support.

4,Packaging Details : nude , covered with wax, small type can be put into 20'GP OR 40'GP container , over sized can be carried by bulk carriers or ro-ro ship , or according to your requirements.

5.Accessories for truck brands:Foton.JAC. FAW .JMC .Dongfeng.Chery.HOWO.Sintruk.Shacman.I-SUZU.I-VECO.etc

6.We offer truck accessories:Wrecker truck, water tank truck, fuel truck, sewage suction truck, aerial work platform truck, fire truck, asphalt spreader truck, garbage truck, dump truck, refrigerated truck, food truck, LED truck, etc.

7. Sample order ,Need to pay shipping.

8. We will reply you for your inquiry in 24 hours.

9. after sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

First, the characteristics and performance of the suction pump suction truck vacuum pump

The XD single-stage multi-rotor series vacuum pump developed by our company adopts advanced foreign technology, high-tech materials and advanced technology. The utility model has the advantages of compact structure, beautiful appearance, high vacuum degree, wide application range, long service life, convenient maintenance, vacuuming and compressed air. Mainly used for large, medium, small-scale dung, sewage-sucking vehicles, industrial and mining enterprises, schools.

Second, the performance parameters

model | Pumping rate | Ultimate pressure Pa | Speed | Power consumption | Inlet and exhaust aperture | Jianyi Applicable models | Maximum pump temperature ( °C ) | |

M3/h | L/S | |||||||

XD-100 | 360 | 120 | -90000 | 950 | ≤13 | ¢ 50 | (8-15)m3 | ≤90 |

XD-80 | 350 | 97 | - 90000 | 950 | ≤10 | ¢ 50 | (4-8)m3 | ≤90 |

XD-63 | 240 | 80 | - 90000 | 950 | ≤8 | ¢ 50 | (3-5) m3 | |

XD-35 | 185 | 52 | - 90000 | 950 | ≤5 | ¢ 50 | (1 - 3) m3 | |

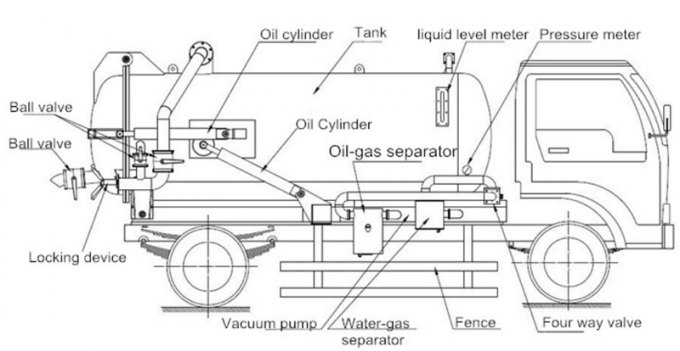

Third, the structure

The XD single-stage multi-rotor series vacuum pump is mainly composed of pump body, rotor, front and rear end covers, rotary vanes, bearings, couplings, etc. The center of the rotor is offset from the center of the pump body.

Fourth, the working principle

When the eccentric rotor rotates, the rotary vane slides against the inner wall of the pump under the action of centrifugal force, and the volume of the suction chamber gradually increases, and the pumped gas is sucked into it until the rotary vane is turned to the end of inhalation, and the inhaled gas is isolated. .

The rotor continues to rotate, the isolated gas is gradually compressed, and the pressure is increased. When the pressure exceeds the pressure of the exhaust port, the gas is discharged outside the pump. This cycle is repeated to evacuate the air in the container to form a vacuum.

Five, installation and commissioning

1. Install the pump on the inside of the girders of the car with suitable shelves and angle irons. The position of the pump is high, low, left and right, front and rear, and the axis of the drive shaft of the power take-off is determined. In the case of non-interference with the components of the car girders, try to Close to the power take-off and the girders. Shaft and the PTO shaft is connected to the inclination angle of not greater than . 7 O C .

2. The suction pipe system is strictly prohibited from leaking, otherwise the vacuum degree will be affected. The exhaust pipe should also be free of leakage to avoid vacuum discharge, pollute the environment and waste energy.

3. The installation position of the oil and gas separator should be such that its oil outlet is higher than the vacuum pump inlet joint. In the cold or cold season, change the anti-freeze lubricant to ensure the smooth flow of the oil. After the first50 hours of use , replace the new lubricant and set it into the cleaning.

Sixth, maintenance

1. Always check the oil quantity and oil quality. If it has been emulsified, it must be replaced with new oil.

2. The water separated by the water separator should be stored in it, and it should be discharged at regular intervals, otherwise it will affect the exhaust.

Seven, faults and solutions

When the pump has a malfunction, it can be solved by referring to the following methods or consulting the manufacturer:

malfunction | the reason | Solution |

Not enough vacuum | 1. The oil inlet pipe is blocked or leaking 2 , the intake line leaks 3 , the V-belt is too loose, the pump speed is not enough 4 , the rotor is worn or damaged 5 , skeleton oil seal wear 6 , measuring instrument distortion, indicating error 7 , four-way valve seal wear, helium | 1 , finishing the oil supply pipeline 2 , tighten the intake line 3 , adjust the belt tightness 4 , replace the damaged rotary vane 5 , replace the skeleton oil seal 6 , replace the measuring instrument 7 , replace the damaged seal |

Pump temperature is too high | 1. The oil inlet hole is blocked or the gas supply is insufficient. 2 , there is foreign matter entering the pump 3 , bearing damage | 1. Clean the oil supply line or increase the oil supply 2 , cleaning the foreign body in the pump cavity 3 , replace the bearing |

Pump outlet injection | 1 , too much fuel 2 , too much oil | 1 , drain oil to oil level 2 , adjust the fuel supply pipe |

Hard to start | 1 , there is corrosion in the pump cavity 2 , the rotor is damaged 3 , the motor or circuit is faulty 4 , the air outlet is closed or blocked | 1 , clean the pump cavity corrosion 2 , change the rotary vane 3. Check or replace the motor or circuit 4 , open the air outlet or clear the air outlet foreign body |

Unusual operation and abnormal sound | 1 , the V-belt is too loose 2 , the screw is loose 3 , there is foreign matter entering the pump cavity 4 , the rotor is broken | 1. Adjust the pulley position 2 , tighten the screws 3 , clean the pump cavity 4 , change the rotary vane |

Sewage truck suction truck vacuum pump installation and precautions

1. The bottom surface of the vacuum pump is installed on the bottom of the suction and discharge bottom. The height of the pump is determined according to the axis of the output shaft of the power take-off. The components are installed according to the principle and schematic diagram.

2. The power of the vacuum pump is obtained by the power take-off at the power take-off window of the automobile gearbox. The driver operates the handle in the cab, and combines the power take-off gear with the gearbox gear through the shift fork, and drives the vacuum pump with the drive shaft.

3. The double pump is installed according to the schematic diagram. The intermediate joint of the four-way valve to the two pump suction pipe and the two pump oil and gas separator outlet pipe should be located in the middle of the pipeline to avoid mutual interference.

4. The installation of the oil and gas separator should be high or low, and the oil outlet of the oil separator should be higher than the oil inlet at both ends of the pump.

Precautions

1. Install 1000 ml of clean lubricating oil into the pump . Do not allow impurities to enter.

2. When installing the vacuum pump, it must be matched according to the model and be sure to be consistent with the rotation direction specified by the pump body.

3. During the use process, pay attention to the amount of lubricating oil in the oil separator and whether the oil inlet pipe is smooth. After 20-50 hours of the first work , the lubricating oil should be replaced and cleaned regularly.

4. In the operation, the tank cannot be shipped too full. It is strictly forbidden to enter the water and enter the foreign matter. After entering the water, the water in the pump must be removed and the lubricant should be replaced. Otherwise, it is responsible for damage.

5. In the cold season, and in the cold regions, when the vacuum pump is difficult to rotate, check whether the water in the pump is frozen or not, and use antifreeze lubricants to ensure that the lubricant can flow in the pipeline to avoid damage to the pump or affect the vacuum.

6. In the suction and discharge operation, the operation should be strictly carried out according to the regulations. When the suction operation is carried out, the suction pipe should be put into the sludge water to form a vacuum inside the tank. When the suction operation is finished, the suction pipe should be installed first to pull out the sludge water surface. The tank is connected to the atmosphere to prevent the lubricating oil in the oil separator from being sucked into the tank due to the negative pressure inside the tank after the shutdown. Before the end of the tank discharge, the handle of the four-way valve should be placed in the “ Ø ” position to allow the air in the tank to pass through the atmosphere, otherwise oil drainage will occur.

7. When the vacuum in the tank does not meet the requirements, first check the tank, pipe joints, and whether the valve is sealed (especially in cold areas, the valve will freeze when the valve is opened to cause the closure is not tight). The seal will directly affect the vacuum. .

8. The water gas separator is not installed in the tank. The separated water will be stored in the separator. After a long time, the water surface will increase, causing the float to float, which will affect the separator exhaust or even close. For this purpose, 50-100 hours should be worked. Open the production valve to remove stagnant water.

9. It is strictly forbidden to adjust the operation. The continuous working time should not exceed 15 minutes.

10. When the concentration of sucking and sucking is large, it must be diluted with water, otherwise the suction and sewage suction operation cannot be completed.

11. The vacuum pump is not allowed to be disassembled and assembled at will. I will not bear any responsibility for the quality problems caused by disassembly and assembly.

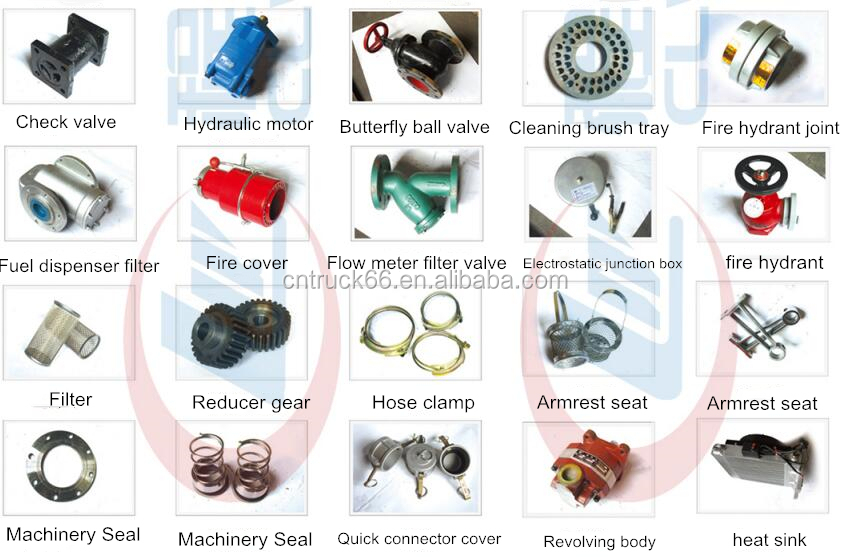

Partial truck accessories picture catalog

1.By cargo bulk shipment or ro-ro shipment .

2.By Flat Rack Container

Trust us

Q1. What is your terms of packing?

A: Generally, we pack the goods in neutral white boxes and brown cartons. Heavy goods will be packed in wooden or wooden pallets.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How about your delivery time?

A: Generally, it will take 5 to 7 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Q9: Accessories include shipping costs?, how to calculate shipping costs?

A:Due to the global sales, the cost of shipping cannot be unified. Therefore, the accessories do not include shipping costs. The cost of shipping costs will be recommended according to the weight of the goods, which is a more suitable transmission channel.

Video

Suizhou, Hubei, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier