1 / 1

wholesale Lifting Pneumatic Mixer

| Brand Name : | HongXin |

|---|---|

| warranty period : | 3months-1year,3years |

Nantong, Jiangsu, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

Product description

Cart Type Pneumatic Lifting Mixer HXDTC-V6-DSP8

Cart Type Pneumatic Lifting Mixer HXDTC-V6-DSP8

IBC barrel Wheeled pneumatic lift mixer

2. product characteristics :

This is mainly composed of an air motor agitator ( vane / piston air motor optional ), bushings , stirring rod and stirring impeller (304 / 316L material optionally ) and pneumatic lifting trolley frame composition , suitable for Stirring of high viscosity solutions in 250 liter buckets . The stirring frame can control the rise and fall of the mixer through the cylinder , and freely adjust the stirring height . The mixer can control the mixing speed by adjusting the intake flow of compressed air to adapt to the requirements of different working conditions , and can work continuously for more than eight hours without temperature rise and heat generation . Under special working conditions, it can realize continuous operation 24 hours a day . It is suitable for chemical , coal mining , papermaking and other industries .

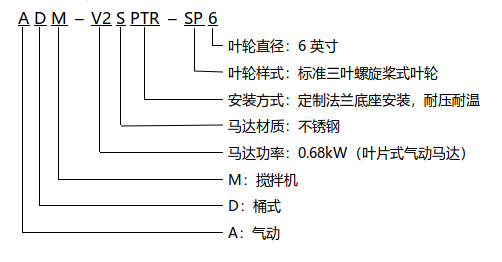

3. Model Description :HXDTC-V6-DSP8

4. Technical parameters

|

mixer model |

HXDTC-V6-DSP8 |

|

Motor model |

HX6AM-ARV-54 Vane Air Motor |

|

Motor power |

3kW (under the condition of 0.69MPa, 3000rpm) |

|

maximum speed |

3000rpm |

|

Recommended speed |

500-2000rpm |

|

316L stirring shaft |

φ19.05×1050mm (material and size can be customized) |

|

316L impeller diameter |

8 inches (impeller material, style, size and surface coating can be customized) |

|

working pressure |

0.4-0.8MPa |

|

Connection size |

1/2" NPT |

|

Trachea diameter |

Outer diameter O.D.=16mm Inner diameter I.D.=12mm |

|

Installation method |

trolley |

|

Maximum air consumption |

3800L/min |

|

Machine quality |

95kg |

|

Applicable viscosity |

≤5000cP |

|

Stirring capacity |

250L |

5. Dimensions

6. Matters needing attention

(1) The mixer must be installed vertically or the installation inclination angle is less than or equal to 15°.

(2) The motor of the pneumatic mixer must be driven by dry, clean and lubricated compressed air, and an air filter, a pressure regulating valve, and a lubricator must be installed in the air system, that is, a joint or a triple piece. The double and triple parts must be installed close to the air motor (within 0.5 meters).

(3) The inner diameter of the nozzle is not less than 6.5mm. Before connecting to the pneumatic mixer, the air path must be ventilated to clean up the debris that may appear inside the air pipe. These foreign objects enter the air motor of the mixer and cause the motor to be stuck.

(4) The motor of the mixer must be lubricated continuously (the lubricating oil enters the air motor with the compressed air after being atomized by the lubricator). Lubrication will reduce the wear of the air motor blades and the corrosion of the internal parts of the motor, and prolong the service life. The lubricating oil label is ISO-VG32 special oil for lubricator or other lubricating oil with the same label. The amount of lubrication is 1-2 drops per minute. If there is no lubricator in the air circuit, 15 drops of lubricating oil can be manually dripped into the motor air inlet before each operation.

Nantong, Jiangsu, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

Send your inquiry to this supplier