1 / 5

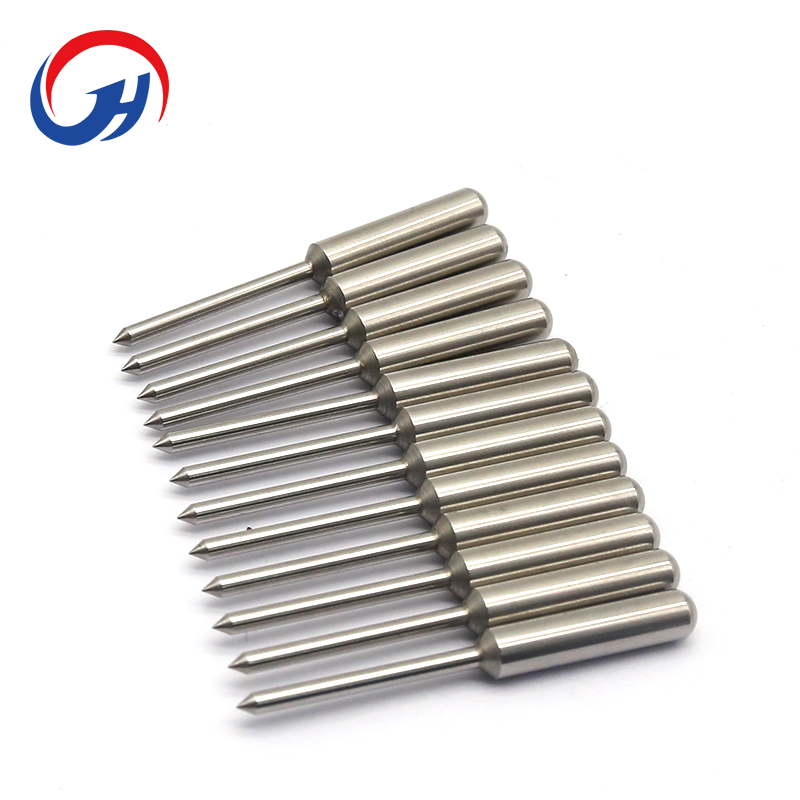

Waterjet cutting machine needle valve repair for KMT

Foshan, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Platform Certification

Product description

Short description

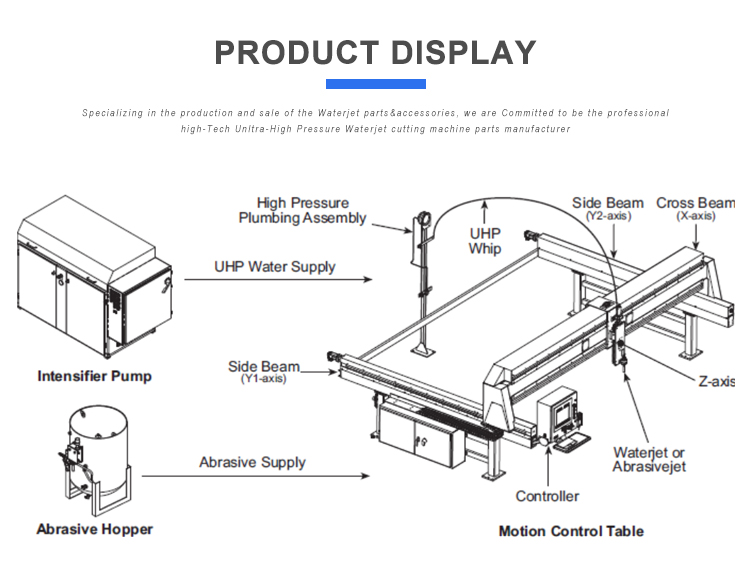

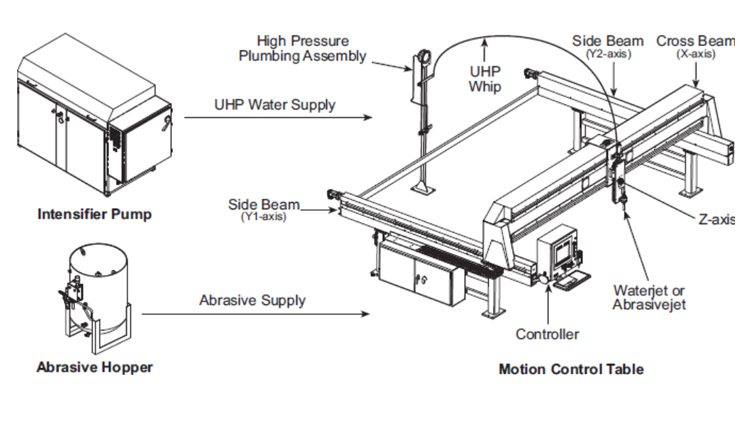

The valve needle is the valve needle in the water switch Maintenance Kit, and the valve needle is installed in the valve body of the water switch. The air cylinder is connected to the air compressor through the air pipe to make it push the rod up and down to control the valve needle in the valve body of the water switch, so as to control the high-pressure water switch.

| Rated power motor | 37KW |

| Maximum | 450MPa |

| Power supply | Local voltage |

| Cooling | Water-cooled,oil-cooled |

| Attenuator | Taiwan high pressure material,1.0L |

| Auto alarming system |

Show you some alarm records,for example,lack of water or oil,leak water or oil,over pressure,over temperature,and maintenance |

| Packing size(mm) | 2350*1330*1500 |

| N.W.(kg) | 1200 |

| G.W.(kg) | 1300 |

| Display screen | 19 inch LCD |

| Computer system | Win 7 |

| Compatible software | ASC,IGS,DXF&DWG,etc graphic design software |

| File to send and receive way | Internet TCP/IP,USB port and PC. |

| Cutting software |

AUTO CAD(Computer aided design)/CAM(Computer aided manufacturing)software |

| Packing size(mm) | 830*750*1550 |

| N.W.(kg) | 180 |

| G.W.(kg) | 230 |

| Comtrol mode | Pneumatics technology |

| Supply capacity | Provide sand with 2 water jet cutting machine at the same time |

| Efficiency | When you add the garnet sand,there is no need |

| Storage power | 200kg |

| Packing size(mm) | 1160*670*π |

| N.W.(kg) | 350 |

| G.W.(kg) | 400 |

| Display screen | 17 inch LCD |

| Computer system | WIn XP |

| Servo driver | Japan(Yaskawa) |

| Compatible software | ASC,IGS,DXF&DWG,etc graphic design software |

| File route | Internet TCP/IP,USB port and PC. |

| Cutting software |

AUTO CAD(Computer aided design)/CAM(Computer aided manufacturing)software |

| Packing size(mm) | 830*750*1550 |

| N.W.(kg) | 180 |

| G.W.(kg) | 230 |

| Cutting Table | Models | HR1212 | HR2015 | HR2515 | HR2520 | HR3015 | |

| Structure | Gantry Working Table/Cantiler Working Table | ||||||

| Cutting Stroke | X Axis | 1200mm | 2000mm/1800mm | 2500mm/2300mm | 2500mm/2300mm | 3000mm/2800mm | |

| Y Axis | 1200mm | 1500mm | 1500mm | 2000mm | 1500mm | ||

| Z Axis | 60~80mm | 60~80mm | 60~80mm | 60~80mm | 60~80mm | ||

| A,B-Axis | ±10°(Remark:3-axis cutting head is without A,B-axis | ||||||

| Speed | Cutting Speed | 1000mm/Min(Normal standard straight cutting,depend on cutting effect | |||||

| Rapid positioning | 6500/15000 mm/min | ||||||

| Accuracy | Cutting Accuracy | ±0.1mm | |||||

| Repeating Accuracy | ±0.05mm | ||||||

Q1.Why should I use waterjet cutting over lasers?

A:Laser cutting is a productive,but waterjets have several advantages over lasers:

1)No thickness limitations.

2)No problems with reflective materials like brass& aluminum.

3)No burning or heat-affected zone.

4)Waterjets can cut heat sensitive material, like plastics, rubber or composites, even glass, stone &ceramics etc

5)It has multiple head for high production

6)Less Specialized maintenance is required than Laser.

7)Less Critical stand off distance between nozzle&Material than Laser.

8)Less capital investment than lasers Typically.

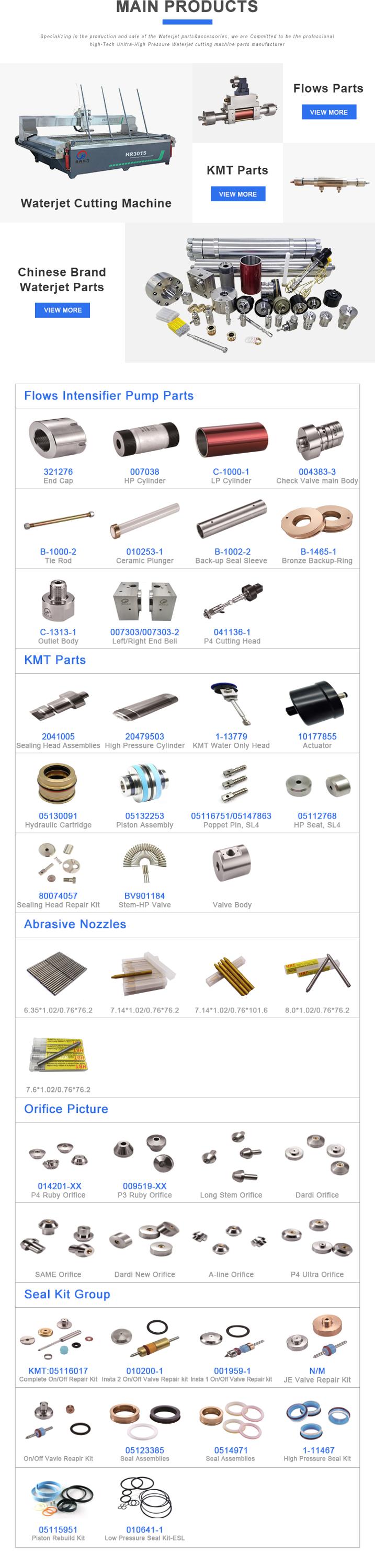

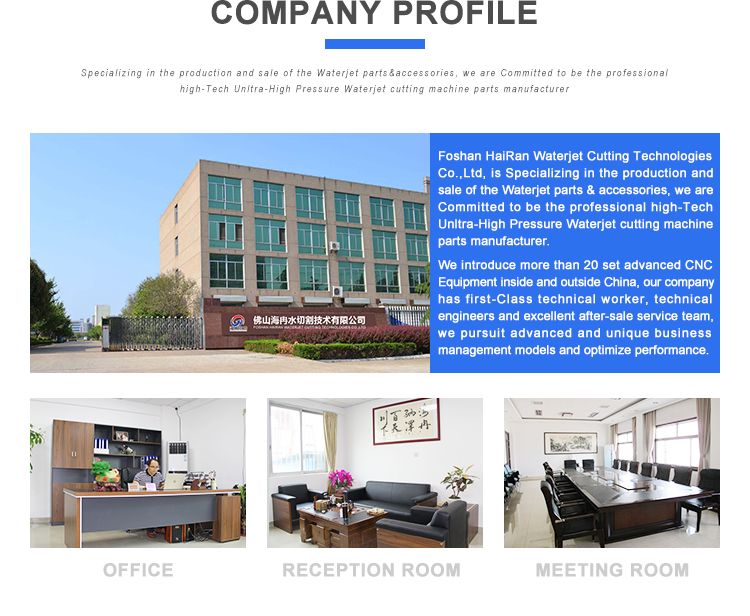

Q2.Are you a factory or trading company?

A:We are factory.We are the professional Manufacturer and produce Ultra-high pressure Waterjet parts and accessories.

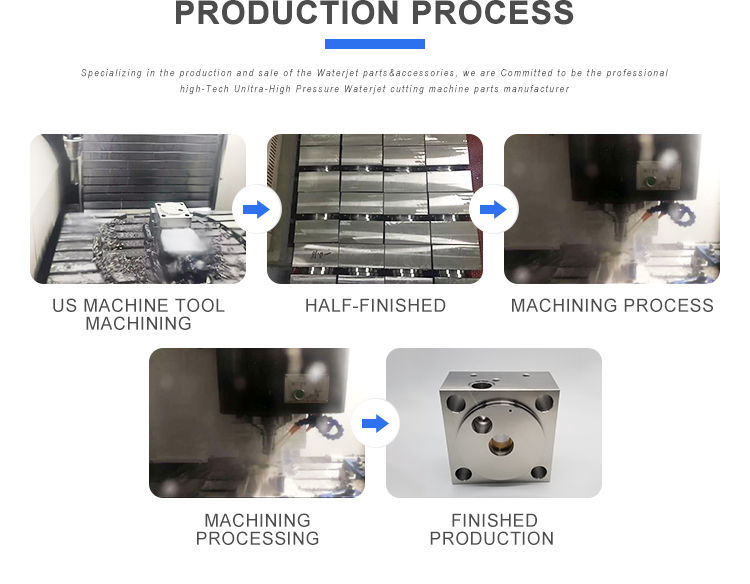

Q3.How about the spare parts quality?

A:Our finished parts and raw materials are from professional and brand name companies. and all the parts have passed the strict quality test and inspection to ensure you the excellent quality waterjet spare parts.

Q4.What about the payment:

A:We accept T/T,Paypal and Western Union, L/C, Credit Card and Alibaba Credit Insurance payment is preferred.

Q5.How thick can it cut?

A:It can cut up to 200mm thick steel& titanium are cut on a production basis.Even 350mm thick material has been cut. Mostly cut between 6mm to 50 thick materials.

Q6.What kind of abrasive are you using?

A:Garnet is the most commonly used abrasive material. Other abrasives include olivine sand, aluminum oxide, and some man-made materials.

Q7.What mesh the abrasive garnet is using?

A:The Abrasive garnet mesh is determined by facts like the nozzles ID,Cutting power,kerf etc, mostly used is 60mesh, 80mesh for Nozzle ID:1.02mm&0.76mm.

Foshan, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Platform Certification

Send your inquiry to this supplier