1 / 3

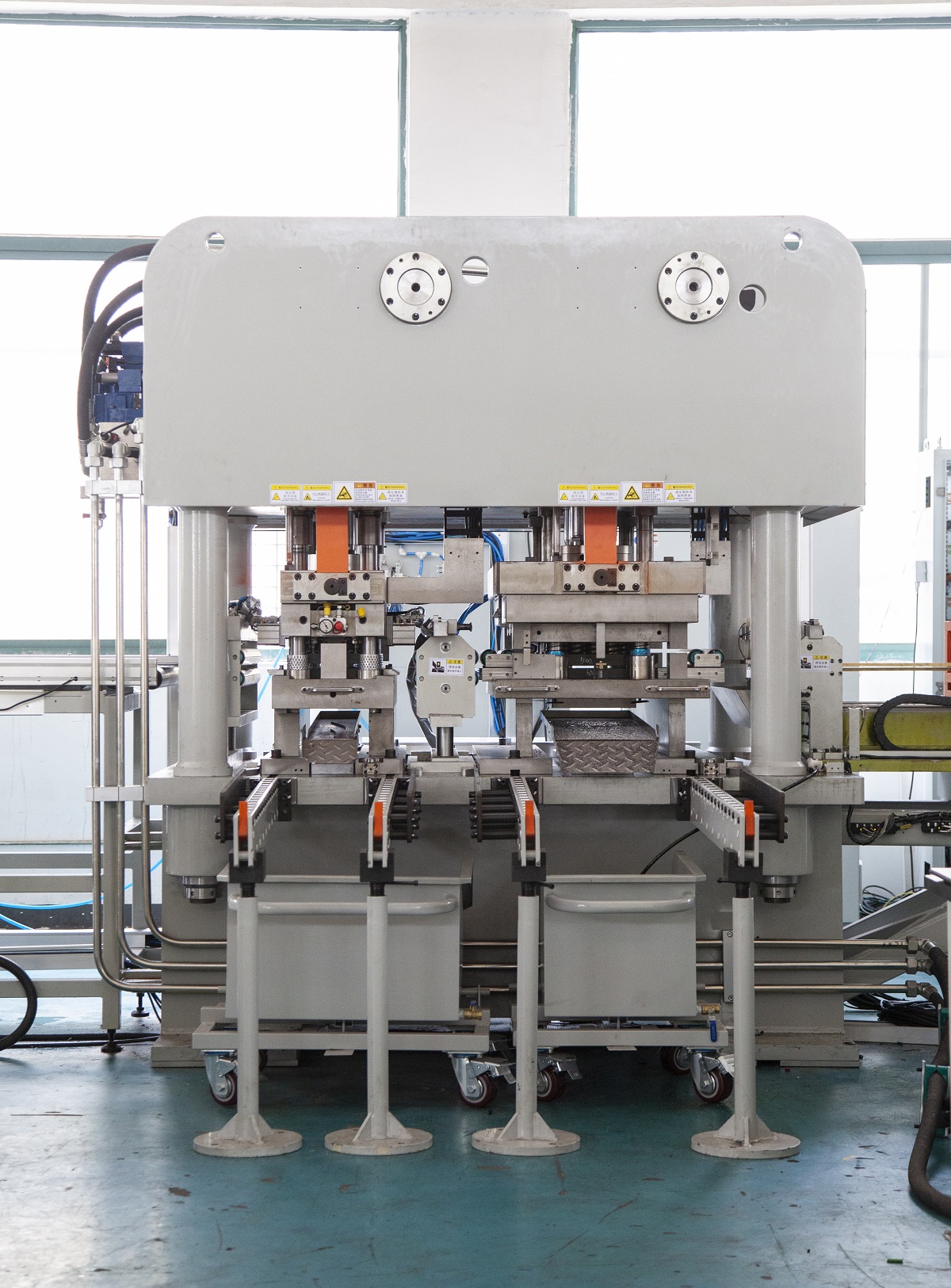

Wash and Dry Station of Drum Blanking Line

| Model No. : | 7580 Washer Drum Line |

|---|---|

| Brand Name : | IDO |

Wuxi, Jiangsu, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Product description

Wash and Dry Station of Drum Blanking Line

The sheet is conveyed from the press through the wash and dry station.And to the weld waiting position via a outfeed conveyed.

Wa

Project Description |

|

| Maximum Loading Capacity | 5000KG |

Internal Coil Diameter Range |

450-550MM |

Coil Widgh Range |

200-500MM |

Maximum Coil Outside Diameter |

1400MM |

Q: Are you a factory or trading company?

A: We are a factory which has been producing metal stamping moulds for more than 10 years.

A: Yes, of course. We can custom make for you based on your drawing or sample

Q: What are your main products?

A: We specialize in designing and manufacturing sheet metal stamping tools/moulds mostly for household appliance and automobile

industry, CNC machining parts and mould supporting facilities etc.

Q: How can I get the quotation?

A: Normally, we can get back to you within 24 hours when getting your detailed 3D drawing and requirements. If the project include

s many different parts, we will try our best to get back asap.In order to quote for you earlier, please provide us the following

information together with your inquiry.

1) 2D and 3D Drawings (DWG, STP, STEP, X_T, IGES, PDF)

2) Material requirement

3) Surface treatment requirement

4) Quantity (per order/per month/annual)

5) Any special demands or requirements, such as packing, labels,delivery,etc.

Q:What technical documentation do you supply?

A:

1)3D Format in STP

2)2D Format in DWG,2D need to be deliver printed as well

3)Parts list complete-compatible with cad data

4)Process map with dimension from the stamped out of every tool step

5)Final design update after final adjustment and final acceptance

6)All standard punching tool who was change must be add to the documentation

7)Manual with photos to explain how assenmbly and disassembly tool

Wuxi, Jiangsu, China

- Manufacturer

- OEM service

- Platform Certification

- Online Expo

Send your inquiry to this supplier