Video

1 / 1

W12NC-10x2000 Four Roller Rolling Machine

| Video factory inspection : | Provided |

|---|

Nantong, Jiangsu, China

- Distributor/Wholesaler

- Manufacturer

- Service

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Product description

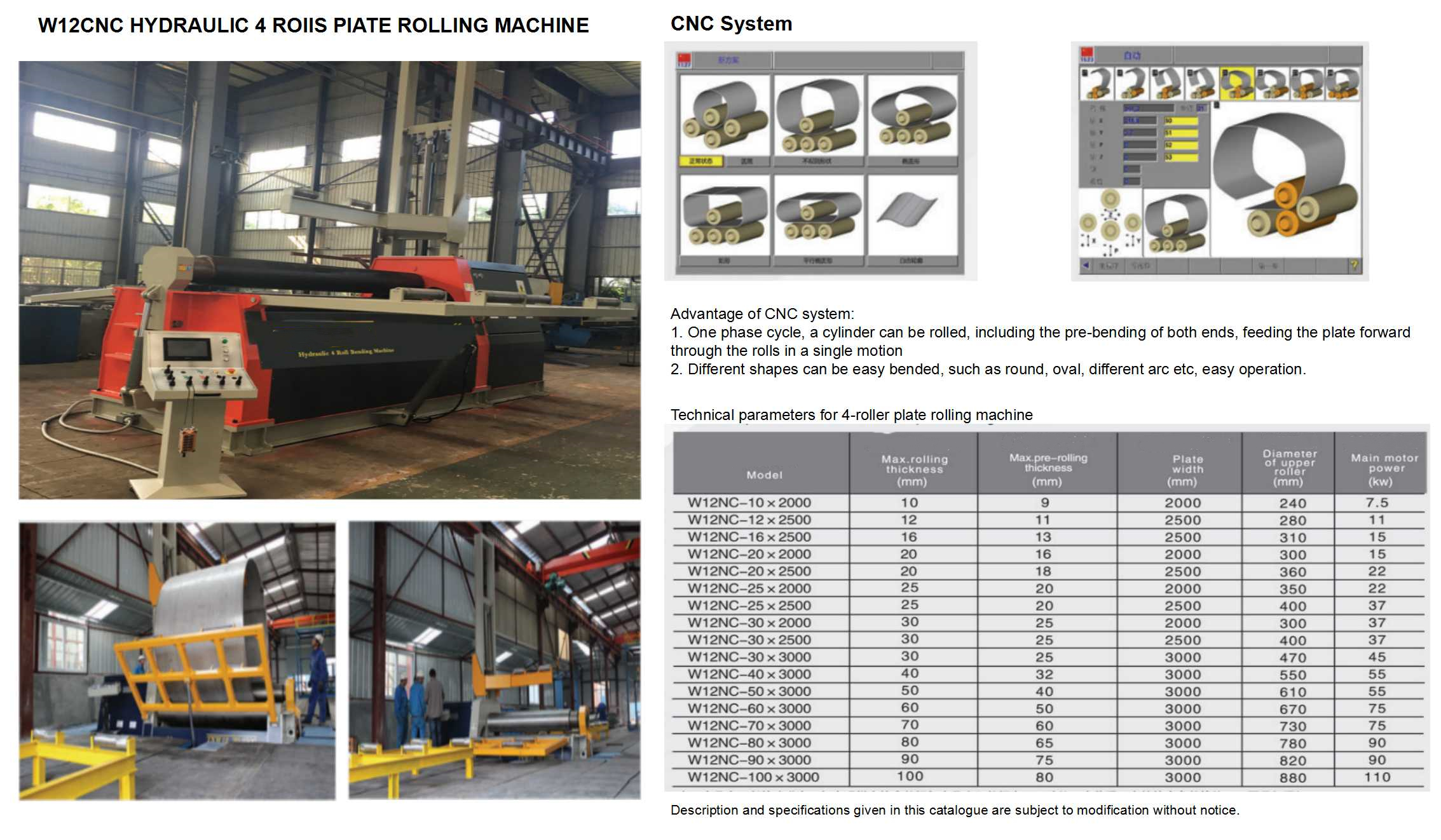

W12CNC HYDRAULIC 4 ROLLS PLATE ROLLING MACHINE

This machine is a hydraulic four -roller bending machine and used to do pre-bending the end of plate, rolling it into round, cone and other shapes.

Main Part and Techniques

No.

Main Machine part

Technical Requirement

1

Top Roller Device

Material

42CrMo

Techniques

forging piece go through rough machining then quenching and tempering treatment at HB260~300

finish turning then medium frequency quenching of surface at HRC48~52

2

Bottom Roller Device

Material

42CrMo

Techniques

forging piece go through rough machining then quenching and tempering treatment at HB260~280

finish turning then medium frequency quenching of surface at HRC48~52

3

Side Roller Device

Material

42CrMo

Techniques

forging piece go through rough machining then quenching and tempering treatment at HB260~280

finish turning then medium frequency quenching of surface at HRC48~52

4

Side Frame and Chassis

Material

Q235 steel

Techniques

Fixed and tipping side frame and chassis are welding pieces of steel plate.

1、welding

2、anneal and vibration

3、the stress shall be eliminated

5

Drive Device

Motor

From china famous supplier

Reducer

From china famous supplier

6

Hydraulic System

hydraulic valve

From china famous supplier

sealing element

From china famous supplier

Oil Cylinder

From china famous supplier

7

Tipping Device

Function

Get bended work piece

8

Control System

Low Voltage Apparatus

SIEMENS GERMAN

PLC

OMRON JAPAN

Touch Screen

TaiWan

Control Console

From china famous supplier

Control program

From china famous supplier

9

Bearing

Double-row Self-aligning Roller Bearing

From china famous supplier

10

Encoder

From china famous supplier

Quality standards

JB/T8796-1998 The precision of plate rolling machine

JB/T 8778-1998 Technical condition of four-roller plate bending machine

JB/T1829-1997 General technical condition of forge and press machinery

GB17120-1997 Safety technical condition of forge and press machinery

JB/T8609-1997 Welding technical condition of forges and press machinery

JB3623-84 Noise measurement way of forge and press machinery

GB3766-83 General technical condition of hydraulic system

GB16754-2008 Urgent stop design principle of machinery safety

GB/T5226.1-2008 Mechanical electric safety mechanical electric equipment

The first part: general technical condition

Video

Nantong, Jiangsu, China

- Distributor/Wholesaler

- Manufacturer

- Service

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier