Video

1 / 6

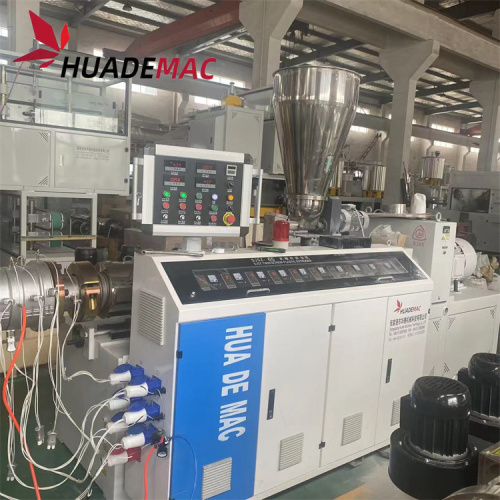

UPVC plumbing tube production machinery

$48000.00

≥1 Set/Sets

$47000.00

≥3 Set/Sets

| Model No. : | 72-200 |

|---|---|

| Brand Name : | HUADE |

| application : | Pipe |

Suzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Product description

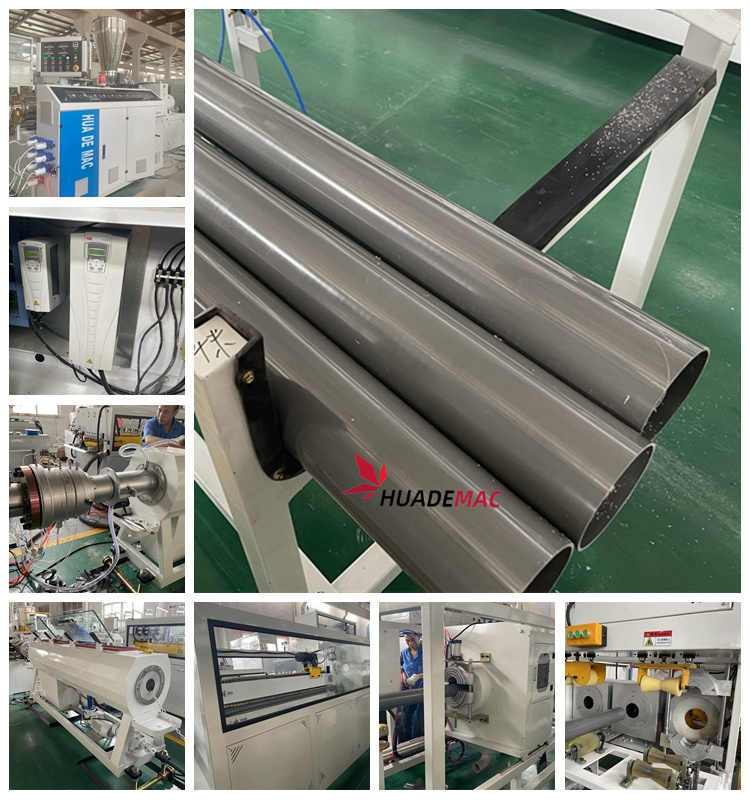

Diameter Range (mm): 50 63 75 90 110 140 160 200mm wall thickness by request

Main Extruder Motor Power: 37kw

Line Space Occupation: 38mx4mx3m

Capacity: 200-250kg/h

Product Description

Application of PVC,UPVC Wall Pipe extrusion production line / UPVC pipe making machine:

Applied for manufacture of caliber PVC,UPVC water supply and drain pipes,electric conduit pipe, etc

Components Of A typical PVC Pipe Production Line

UPVC pipe production line is comprised of a number of machines as following:

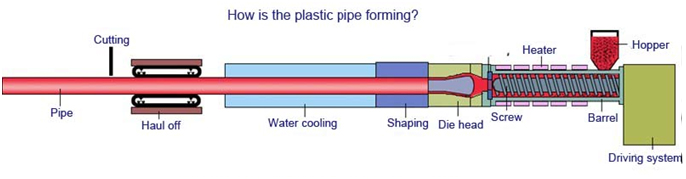

Extruder machine: The starting point and heart of every pipe production line, the extruder machine heats and melts virgin or recycled plastic materials,delivering it to the pipe extrusion die head.

Pipe extrusion die head: Forms the extruded plastic into the desired pipe profile.

Vacuum & Cooling Tank: Cooling of the produced pipe, at a precise temperature range in order to cool and stabilize the pipe in the desired shape.

Haul off/puller: Pulling of the pipe after cooling, ensuring consistent pipe thickness and dimensional stability.

Pipe cutter: Positioned after the haul off machine, for cutting of the extruded pipe in the desired length during production.

Stacking Unit:put after cutter for straight pipe laying for late transportation and use.

Belling machine comes at the end,belling is the process of heating the end of a PVC tube and expanding its diameter using a mold.The enlarged end is called a bell, socket or the male-end.

Working flow of PVC,UPVC Wall Pipe extrusion production line / UPVC pipe making machine

Details Images

Video

Suzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier